GRUNDIG Service

3 - 5

k

TVR 3710 …, TVR 5100 …, TVR 5500 …

Adjustment Procedures

GB

Adjustment Procedures

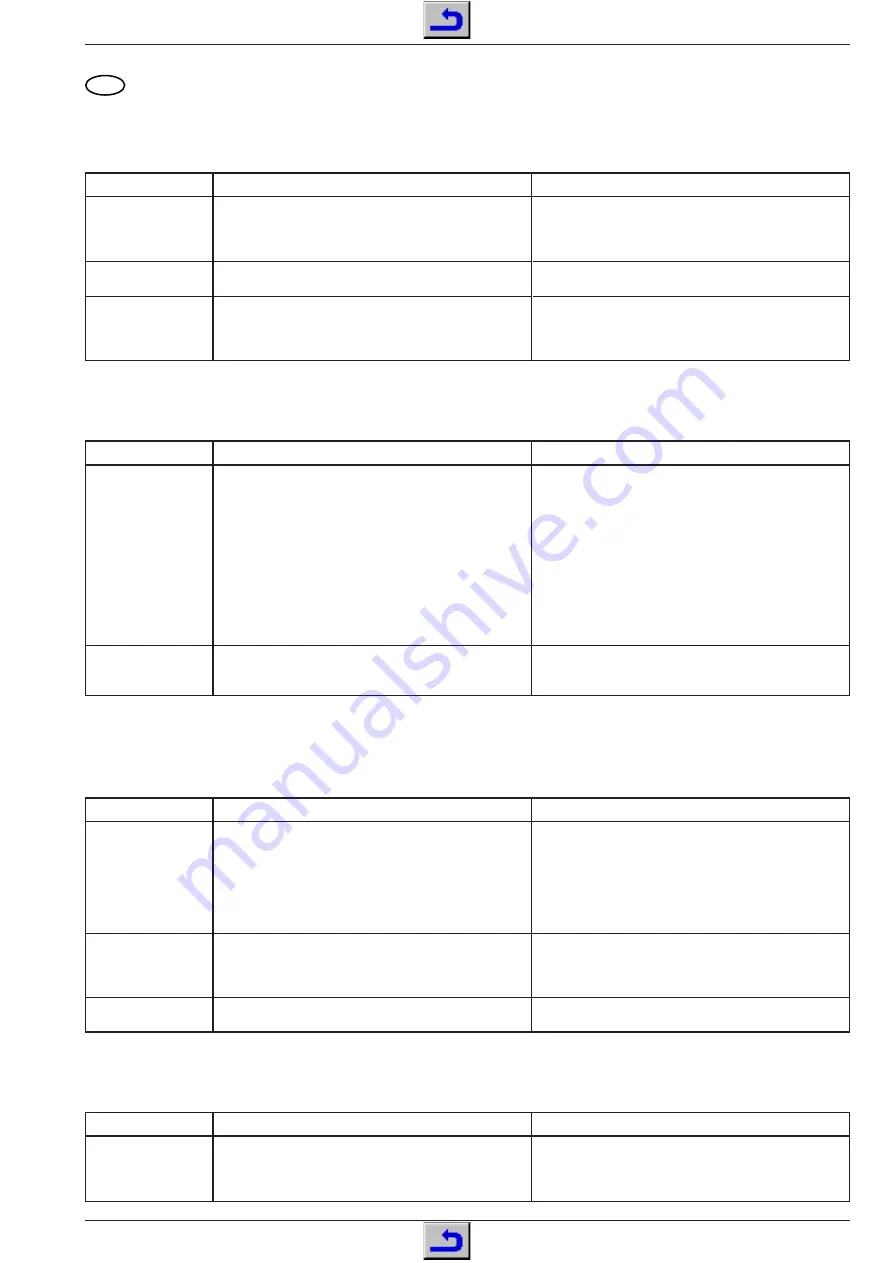

1. Power Chassis (PLSP)

Test Equipment / Aids: Digital Voltmeter, Colour Generator

Select AV programme position without feeding in a signal.

Set contrast and brightness to "minimum".

Digital voltmeter: ................................................. 1925-(2)

Feed in a crosshatch pattern signal.

Feed in a FuBK test pattern.

With R3358

(Ubat)

set the following voltage according to the

different models:

TVR3710...

100.9V

TVR5100...

117.8V

TVR5500...

82.6V

Adjust the focus control (FOCUS) on the line transformer

to obtain the sharpest crosshatch pattern possible.

With the adjustment controls R3523

(V-amp)

and R3524

(V-shift)

adjust the picture to obtain a round circle with half

a square of the pattern being visible at the top and at the

bottom of the circle.

1. 110V operating

voltage

R3358

(Ubat)

2. Focus adjustment

FOCUS

3. Vertical picture

R3523

(V-amp)

R3524

(V-shift)

Alignment

Preparation

Alignment Procedure

2. Tube PCB

Test Equipment / Aids: Digital Voltmeter, Colour Generator

Alignment

Preparation

Alignment Procedure

Turn the screen adjustment control (SCREEN) on the

line transformer until the beam just becomes invisible

again. Repeat this brightness ajdustment at the individual

cathodes using the respective controls R3920

(RED-Cutoff)

,

R3918

(GREEN-Cutoff)

and R3917

(BLUE-Cutoff)

.

Set R3919

(GREEN-Gain)

and R3921

(BLUE-Gain)

so that no

discolouration is visible in the grey scale.

1. Black level

SCREEN

R3920

(RED-Cutoff)

R3918

(GREEN-Cutoff)

R3917

(BLUE-Cutoff)

2. White balance

R3919

(GREEN-Gain)

R3921

(BLUE-Gain)

Allow the set to warm up (for approx. 15 minutes after

switching on) and carry out the following adjustments:

– Contrast "84% = maximum minus 4 divisions on OSD scale"

– Brightness "50%"

– Screen grid adjustment control (SCREEN) "left stop"

– R3919, R3921 "center position".

– Feed a black test pattern into the AV socket.

– With the cutoff controls R3920, R3918 and R3917, set the

following levels at the R, G, and B inputs of the picture

tube dependent on the TVR model:

TVR 3710 … / TVR 5100 …:

115V

TVR 5500 …:

140V

Feed in a grey scale pattern.

3. Signal Chassis (PSSP2)

3.1 Signal Chassis – TV Signal Electronics (TV)

Test Equipment / Aids: Digital Voltmeter, Oscilloscope, Colour Generator

Alignment

Preparation

Alignment Procedure

1. Demodulator

circuit

PAL, L5705

(AFC1)

SECAM-L,

R3729

(L´ADJ1)

2. Start-up of the

tuner control

voltage

R3712

(AGC1)

3. Horizontal position

R3206

(H-SHIFT)

Connect tuner 1701/1702-(5) to GND.

Digital voltmeter: ............ keyboard control – IC7801-(24)

Reception: PAL-BG

Colour generator 38.9MHz, 35mV

rms

to tuner 1701/1702-(17)

Reception: SECAM-L, band 1 (channel 04)

Colour generator 33.95MHz, 35mV

rms

to tuner 1701/1702-(17)

R3712 to "left stop"

Feed in a white test pattern without sound carrier (UHF range,

channel 24, 67dB

µ

V aerial signal) into the warmed up TVR .

Oscilloscope: ................................. tuner 1701/1702-(17)

Feed in a FuBK test pattern.

Adjust the voltage to 2.5V

±

0.2V with L5705

(AFC1)

.

Adjust the voltage to 2.5V

±

0.2V with R3729

(L´ADJ1)

.

Disconnect GND.

With TDA8361/N5 (IC7200) fitted:

With R3712

(AGC1)

set the voltage to 500mV

pp

-1dB.

With TDA8362/N5 (IC7200) fitted:

With R3712

(AGC1)

set the voltage to 400mV

pp

-1dB.

Adjust with R3206

(H-SHIFT)

so that the no longer visible edges

at the right and left of the picture are symmetric to the screen.

3.2 Signal Chassis – Keyboard Control Unit (CO)

Test Equipment / Aids: Frequency Counter

Adjust the period to 122000ns

±

0.035ns with C2814

(CLOCK)

.

Remove the 1k

Ω

resistor and the GND connection.

Connect IC7801-(7) and IC7801-(64) via a 1k

Ω

resistor.

Connect IC7801-(28) to GND.

Frequency counter: ......................................... IC7801-(7)

Connect the TVR to the mains.

Alignment

Preparation

Alignment Procedure

1. Clock,

C2814

(CLOCK)