GRUNDIG Service

2 - 11

k

TVR 3710 …, TVR 5100 …,TVR 5500 …

Descriptions

Beam Spot Suppression and CRT Discharge

When switching off a TVR the line output transformers 5550 of which

are not provided with a bleeder resistor, the picture tube must be

discharged separately and afterglow of the screen must be prevented.

For this, the rectified heater supply for the emitter stage T7902 is

stopped. The transistor stage T7901 which follows will conduct and

pulls the reference voltage of the RGB amplifier stage to chassis

potential. As a result, the picture tube is fully driven and discharged.

Because there is no focusing voltage, there is only a diffuse spot to be

seen on the screen.

In line output transformers 5551 with integrated bleeder resistor, this

resistor takes over the function of discharging the picture tube. To

ensure that the electron beam is immediately cut off when the TVR is

switched off, grid 1 of the picture tube is also cut off. For this, C2911

is charged up to +180V during operation. When the TVR is switched off,

so does T7902 and T7903 conducts. Consequently, the positive plate

of C2911 receives chassis potential via T7903 and grid 1 of the picture

tube is driven at reverse polarity.

3. Signal Chassis (PSSP2)

3.1 Signal Chassis – Deck Control /

Deck Electronic (DE)

Function Overview

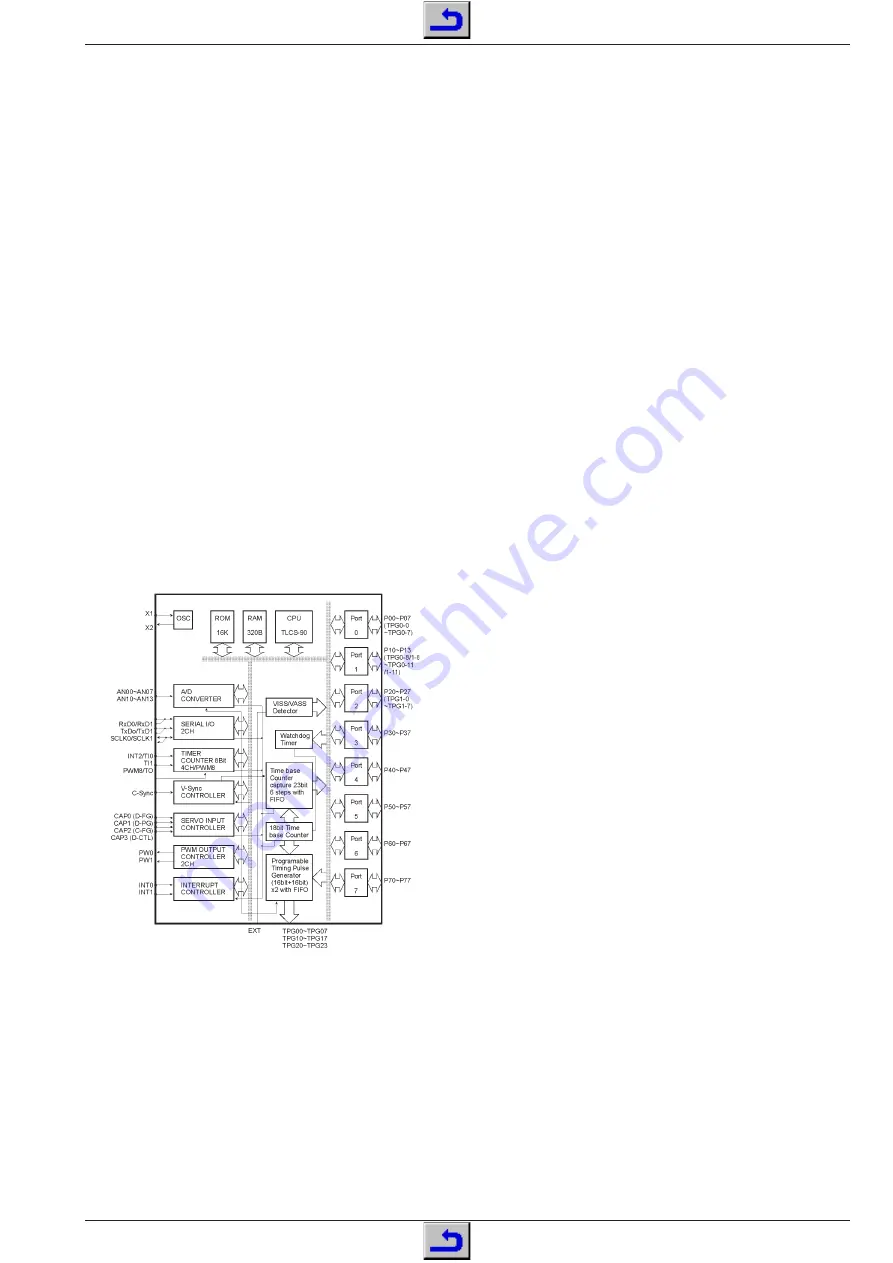

Deck control is effected by the deck computer IC7410, TVC (Toshiba

Video Controller) together with the microcomputer IC7801 on the

keyboard control unit. Data communication between the two micro-

computers takes place via the bidirectional serial interface DATD1 /

DATD2 / CLKD1.

The deck computer is a microcomputer especially developed for video

recorders. The operating system stored in the integrated mask-

programmed ROM of the

µ

C is defined by the VCR option code in the

EEPROM (see Service Test Programme - Option Code). The comput-

ing speed is determined by quartz Q1400.

The deck computer is responsible for driving and checking the tape

deck including the servo systems for the tape transport and headwheel

control. It also controls the record/playback switching process and the

release of the recording currents.

The deck control consists of the following function groups:

3.1.1 Reset

3.1.2 Threading Motor Control

(cassette compartment / threading mechanism)

3.1.3 Winding Tachopulse Processing

3.1.4 Beginning of Tape / End of Tape Detection

3.1.5 Head Servo Control

3.1.6 Tape Servo Control

3.1.7 Tracking / Autotracking

TMP91C642

3.1.1 Reset

When connecting the video recorder to the mains, the IC7411 gener-

ates the switch-on reset pulse with the reset capacitor C2454 on pin 4.

The resulting "POR" (Power On Reset) on IC7411-(17) is applied once

as a HIGH pulse (approx. 30ms) via T7405 to the deck computer

IC7410-(46) "IPOR". On another path, this "POR" pulse is also fed via

the phase-shifting delay circuit T7805 on the keyboard control unit to

the control computer IC7801-(47) as a negated pulse.

3.1.2 Threading Motor Control (cassette compartment /

threading mechanism)

The cassette compartment and threading mechanism is driven by the

threading motor. For driving the threading motor, the deck computer

IC7410 feeds out the control signals TMO (Pin 53) and THIO (Pin 16).

These signals drive the threading motor via the threading motor driver

IC7402-(5/6, 7/8) and plug contact 1903-(1/3).

The

µ

C detects the position of the tape deck by counting the threading

tachopulses (FTA) in connection with the INIT switch and the identifi-

cation "TAS" for the beginning of the tape, and "TAE" for the end of the

tape. The threading tachopulses (FTA) are supplied to the

µ

C via plug

contact 1905-(11) and IC7411-(5/15) (FTAD). The tape deck is fitted

with a switch for initialisation of the threading tacho (INIT) and another

for erase protection (RECP). The voltages resulting from the switch

settings are coupled via the plug contacts 1905-(14/10), R3471 (INIT)

and R3472 (RECP) and fed to the IC7410-(56).

The cassette compartment is mechanically connected with the thread-

ing tacho generator (vane wheel). When loading a cassette into the

cassette compartment, the cassette must be inserted as far as is

necessary to generate three threading tachopulses. Afterwards, the

deck computer activates the threading motor which then takes over the

loading of the cassette.

When ejecting the cassette, the phototransistor detecting the begin-

ning of the tape is released mechanically a short time before the lift

reaches the end position. A short time later, the threading motor is

automatically switched off by the sequence control computer.

3.1.3 Winding Tachopulse Processing

The optocouplers on the left (WTL) and right (WTR) reels produce 8

pulses per revolution. These pulses are formed into rectangular

signals by IC7411 (pins 7/6 –> pins 13/14) and applied to pins 15

(WTLD) and 14 (WTRD) of IC7410. This IC calculates the instantane-

ous tape position and the total length of the cassette from the ratio of

these two frequencies.

3.1.4 Beginning of Tape / End of Tape Detection

To identify the beginning of tape and end of tape, the VHS cassette has

a clear foil, 13 -19cm long, on each end of the tape. The beginning and

end of tape is identified by two optocouplers. For this purpose, the

transmitting diode which is triggered by T7490 is inserted into a hole

in the middle of the cassette. The phototransistors are located at the

outside, left and right, of the cassette.

The phototransistors "TAS" (beginning of tape) or "TAE" (end of tape)

supply pulses as soon as they detect the beginning or end of tape. The

output voltages of the phototransistors are fed via the plug contacts

1905-(15/7) to the analog inputs of the

µ

C IC7410-(55/57).

3.1.5 Head Servo Control

The head servo control ensures that the rotational speed and the

phase of the headwheel drive are correct. The complete control is

carried out in the

µ

C (IC7410). The actual values are derived in the

headwheel motor driver (IC7301) on the head amplifier board from the

information given by the Hall generator or the position coil located in the

headwheel motor (threephase motor) in connection with the phase

voltages. At the output IC7301-(6) there are the PG (phase generator)

pulses of 25Hz for the phase control and also the FG (frequency

generator) pulses of 450Hz for the speed control. From the connector

1904-(1) the PG/FG pulses are fed to the deck computer IC7410-(18).

On IC7410-(30) the

µ

C feeds out a pulse-width-modulated square-

wave signal (REEL) containing information on the speed and the

phase. This signal is fed via the plug contact 1904-(6) to the headwheel

motor driver IC7301 located on the head amplifier board and is used

as a control voltage.

3.1.6 Tape Servo Control

The capstan motor is a three-phase motor which is fitted with Hall

generators. These generate signals which are fed to the capstan motor

driver IC (LB1897) in the capstan motor assembly via the pins 8…13.

Depending upon these signals the IC commutates the individual

phases of the capstan motor.

Switching over of the sense of rotation (CREV) is carried out via pin 26

of the LB1897. For this the

µ

C (IC7410) feeds out from pin 44 a LOW