English (GB)

4

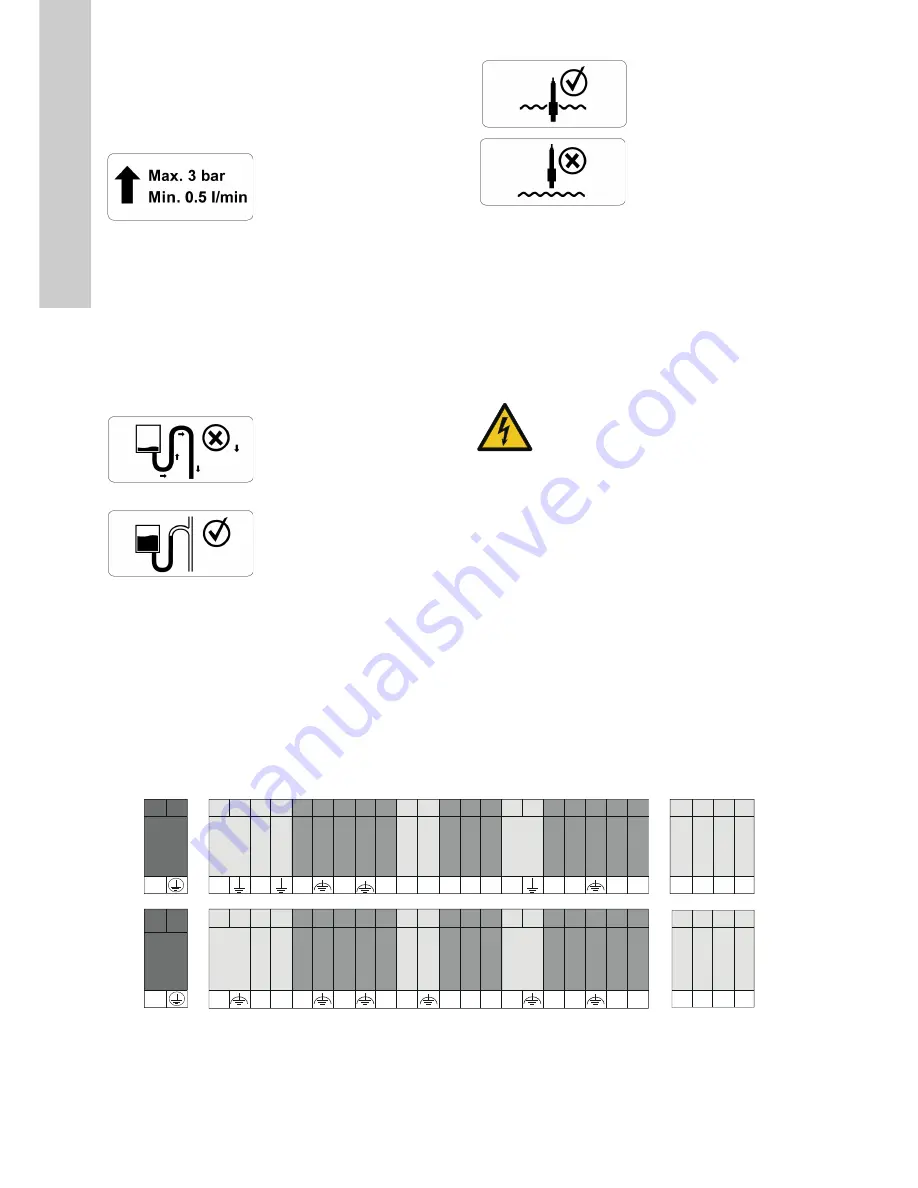

Please note the pressure and flow limitation of the DID as

explained in the technical data on the warning label. Independent

of the inlet discharge the flow within the DID will be reduced by

the flow restrictor to the correct amount.

• Mount the customer outlet tube onto the 1/2" outlet fitting

• Ensure proper layout of the outlet tube to avoid soaking

The tubing on the outlet has to be designed in that way that a

draining of the flow cell is not possible. To ensure this a vented

outlet has to be used. Furthermore no shut-off valve should be

used to avoid back pressure within the flow cell.

• Install strain-relief in case of long / heavy outlet tubes to avoid

mechanical load of the flow cell.

• Due to sealing plugs on in- and outlet, proper 1/2" fittings have

to be mounted by the costumer (part of delivery).

• High loads due to heavy tubes on the outlet port of the flow

cell can damage the mounting of flow cell. Therefore it is

recommended to install a strain-relief for the outlet tubing.

4.4 Installing of sensors

All sensors used in the DID are packed separately to avoid any

damage. They have to be prepared before installation according

to the section Installation in the sensor manual. Within this

manual you will also find a detailed explanation how to mount the

sensors into the flow cell.

As soon as the sensors are ready for operation they should be

wetted all the time. All sensors equipped with electrolyte and

membrane cap have to be powered all the time.

4.5 Checking of tightness

Carefully open the inlet valve on the inlet and check for any

leakage of the DID. Check if any air bubbles are visible within the

tubes and spill them out by temporary increase of the discharge.

5. Starting up the product

5.1 Initial startup

Once the mounting and installation have been completed and

checked, the initial start up of the DID will require the following

actions, in the order presented below:

Described below are the steps that are specific for the DID and

that are not covered in the specific manuals of the sensors

included in your DID. The DID specific actions are to be

performed in the following order:

1. Connect all sensors to the control unit CU 382

2. Open inlet valve slowly

3. Check for leakage in the hydraulic system of the DID

5.2 Terminal connection

Once the cover has been opened (two cross head screws

removed) you have access to the cable terminal compartment of

the control unit CU 382.

Be aware that cable clamps of relay contacts you have connected

to the device might also have power supply (230 VAC),

depending on how they have been interconnected!

Fig. 2

Plan of terminal connections within control unit CU 382

WARNING

Electric shock

•

Switch off the power supply before installing!

Enclosure class IP65 is only guaranteed if the

terminal cover is correctly sealed, if the front

panel of the terminal enclosure is closed and the

appropriate cable glands or dummy caps fitted.

•

This type of work must be carried out by

authorized persons only and after disconnecting

the power supply!

T

M

06

59

58

03

1

6

1 3

5 7 9

RS485

11 13 15 17

21 23 25 27 29 31 33 35 37 39 41 43 45

47 49 51 53

2 4

6 8 10 12 14 16

20 22 24 26 28 30 32 34 36 38 40 42 44 46

48 50 55 54

18

19

12 V Out

GND

4/20 #1

4/20 #2

4/20 #3

4/20 ln #1

4/20 ln #1

ln #1

ln #2

Flow #1

RS485

MOD 1

MOD 1

MOD 2

MOD 2

Relay 1

Relay 2

∑ Err

∑ Err

RS485

Valve

Clean in

4/20 #1

4/20 #2

4/20 #3

4/20 ln #1

ln #1

ln #2

Flow #1

RS485

MOD 1

MOD 1

MOD 2

MOD 2

Relay 1

Relay 2

∑ Err

∑ Err

90...240 V

A

C

90...240 V

A

C

P

A-

A-

PS

+

+

+

+

+ + +

NO NO NO NO

N

B+

B+

-

+

-

-

-

-

-

C C C C

+