GENO

®

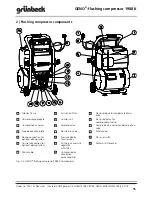

-flushing compressor 1988 K

Order no. 015 151 963-inter Created: KONS-gmei-mrie G:\BA-151963-INTER_GENO-SPUELKOMP-1988_K.DOC

25

Case with flushing fittings, 20 flushing fittings with accessories

In order to use these flushing fittings, the above mentioned closing

plugs are needed. See case with closing plugs or set of closing plugs.

The flushing fitting is connected to the closing plug for flushing and

serves to drain off the flushing water when flushing through piping. It

can also be used to draw off construction water, to fill baths and

showers and bridge piping (for this use a pressure-resistant tube.

The flushing fittings are made up of 2 parts, a shut-off ball fitting and

screw-off tube connection, both of which are made of chrome-plated

brass. Thanks to the ball-type shut-off valve, a large and free cross

section for the flushing is available. The screw-off tube connection

allows the tube to stay fitted to the nozzle.

As the closing plug and the flushing fitting are two separate entities,

only the closing plug remains behind at the construction site for the

time between installation and start-up. Thus, the flushing fitting can be

used at several construction sites - just like a tool. Furthermore, the

introduction of impurities due to unauthorised access is prevented.

Consisting of:

20 flushing fittings.

20 hose clamps.

1 roll of tubing, 15 m

Mounting instructions.

Complete in 130 mm Sortimo case, suitable for

Sortimo vehicle equipment.

151 180

Hose for flushing fittings

50 m roll

151 648e