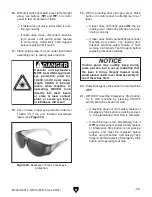

Gases and fumes generated by laser

machines are hazardous to your health. It

is your responsibility to install a dedicated

and rated fume extractor if toxic gases or

fumes are produced during laser cutting

operations.

Dust and embers from laser machines pres-

ent a fire hazard. DO NOT direct exhaust

ports anywhere combustible materials exist,

or combine laser extraction fan with wood-

working dust collection systems.

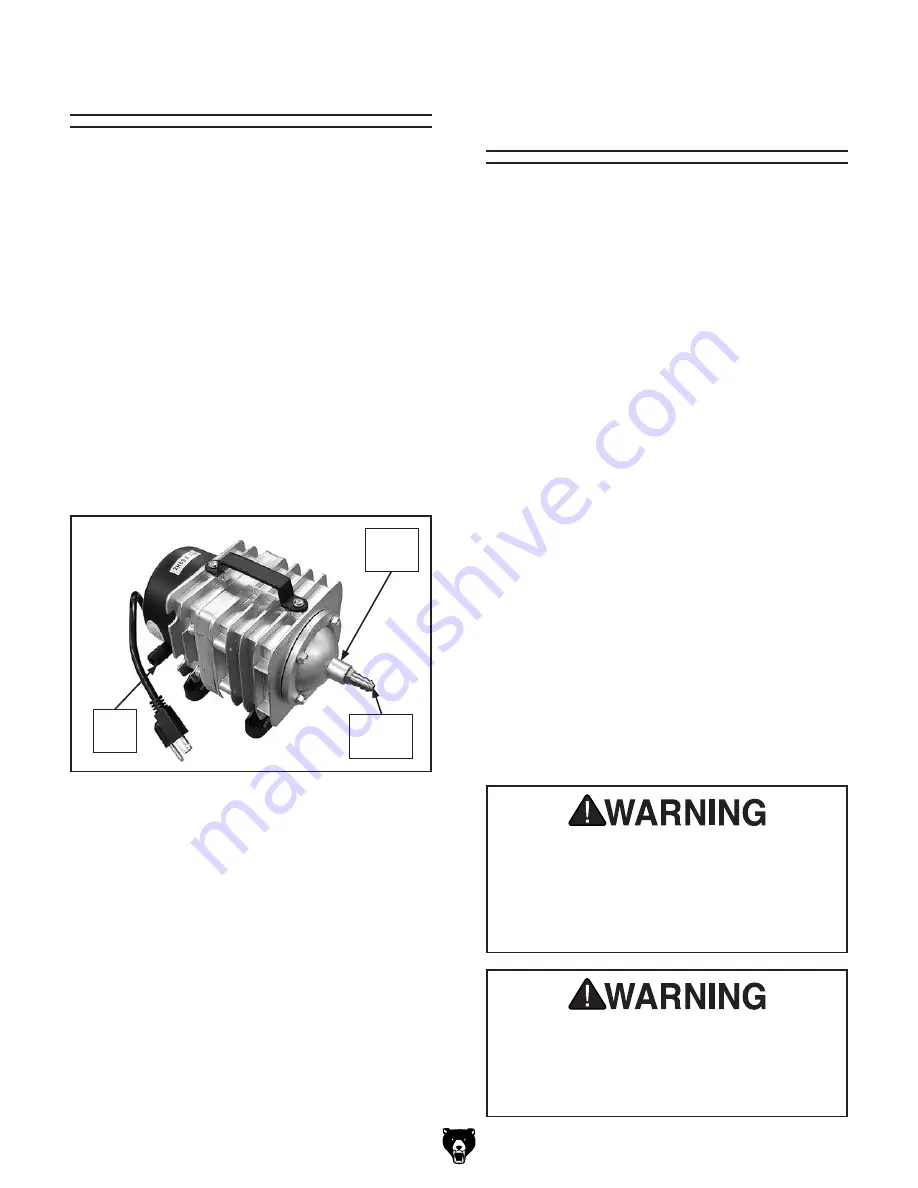

Figure 21. Air pump components.

Model G0911–G0914 (Mfd. Since 05/21)

-25-

Installing Air Pump

The air pump is designed to blow air directly on

the laser focal point. Place the air pump away

from areas where dust can be drawn in through

the inlet port.

Note: A barbed fitting on the inlet port can be

fitted with a hose to draw air from an alternate

source, if required.

The pump has cooling fins to release heat during

operation and should NEVER be located inside of

an unventilated compartment, or any area where

temperature will increase from pump operation.

To install air pump:

1. Thread barbed fitting into air pump outlet port

and tighten (see

Figure 21).

2. Install air pump tubing onto outlet port barbed

fitting and connect to auxiliary systems AIR

IN fitting (see

Figure 18 on Page 24).

3. Place air pump, electrical cord, and hoses

in a location that prevents tripping hazards,

hose kinks, and abrasive damage.

Note:

The air pump generates vibrations

and should be secured to prevent pump from

"walking" during operation.

4. Connect air pump to power supply.

Note:

Air pump can be connected to auxiliary

power connection on rear of machine.

Installing

Extraction Fan

The extraction fan vents debris and fumes cre-

ated during laser operations using a centrifugal-

style fan. The extraction fan should be mounted

in a fixed location that reduces vibration, and the

inlet and outlet ducting should be secured at each

end to prevent separation. Extending ducting over

six feet, or adding multiple elbow connections is

NOT recommended due to reduced extraction

efficiency.

The extraction fan does not remove residual

odors from the machine when not in use. If mate-

rials have an unpleasant odor while being cut,

consider re-locating the machine to an area with

greater ambient ventilation.

If mandated by local fire codes, a spark arrester

may have to be incorporated into the extraction

system. One example of this is when the outlet

duct is connected to a vented container partially

filled with water. Inside the vented container, one

or more baffles are used to direct smoke and

embers toward the water, which will then naturally

rise up and outward from a vent on top of the

container.

IMPORTANT: The machine and extraction fan

are only to be used for laser cutting operations.

DO NOT use machine as a downdraft table for

sanding or other operations.

Outlet

Port

Barbed

Fitting

Inlet

Port

Summary of Contents for G0911

Page 100: ......