-62-

Model G0899 (Mfd. Since 10/20)

Lubrication

It is essential to clean components before lubri-

cating them because dust and chips build up on

lubricated components and make them hard to

move. Simply adding more grease to them will not

yield smooth moving components.

Clean the components in this section with an oil/

grease solvent cleaner and shop rags.

If you thoroughly clean the components in this

section before lubricating them, the result will

be silky smooth movement when turning the

handwheels, which will result in much higher

enjoyment on your part!

Figure 110. Worm and bull gear location.

Worm Gear

Figure 111. Leadscrew location.

Clean away any built up grime and debris from the

worm gear, bull gear, and leadscrew (see

Figures

110–111) with a wire brush, rags, and mineral spir-

its. Allow the components to dry, then apply a thin

coat of grease to them.

Worm Gear, Bull Gear & Leadscrew

Items Needed

Qty

NLGI#2 Grease or Equivalent ........... As Needed

Mineral Spirits .................................... As Needed

Clean Shop Rags .............................. As Needed

Lubrication Type ... T26419 or NLGI#2 Equivalent

Amount ..........................................................Dab

Lubrication Frequency .....................6–12 Months

Trunnion Slides

Lubrication Type ... T26419 or NLGI#2 Equivalent

Amount ..................................................1-2 Dabs

Lubrication Frequency .....................6–12 Months

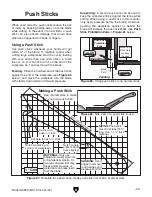

Clean out the front and rear trunnion slides with

mineral spirits and a rag, then apply grease into

each groove. Move the blade tilt back-and-forth to

spread the grease (see

Figure 109).

Leadscrew

Figure 109. Trunnion slide locations.

Trunnion

Slides

Bull Gear

Summary of Contents for G0899

Page 92: ......