Frankenrunner User Manual

Rev 1.0

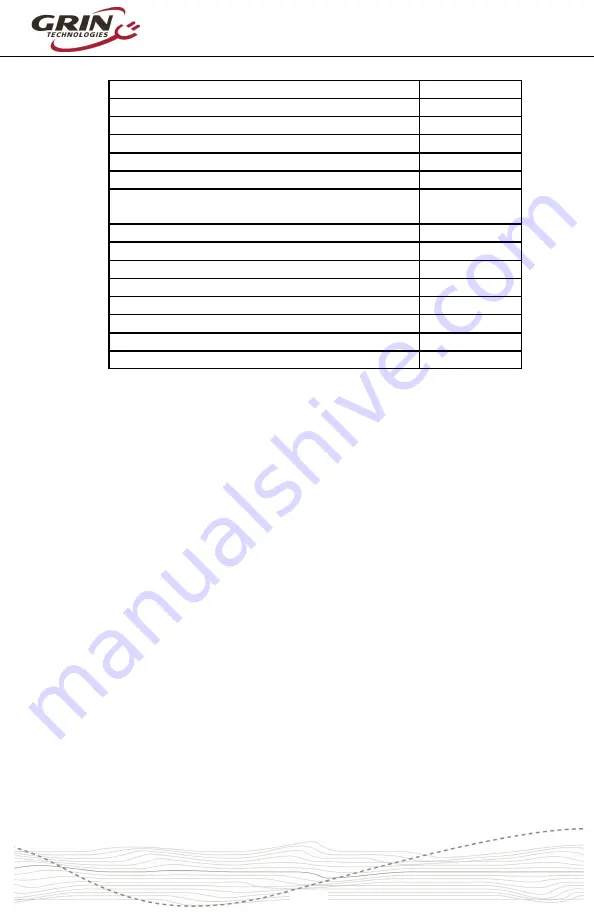

Table 1: Effective Pole Pairs of Common DD and Geared Hub Motors

Motor Family

# Pole Pairs

Crystalyte 400, Wilderness Energy

8

BionX PL350

11

Crystalyte 5300, 5400

12

TDCM IGH

16

Crysatlyte NSM, SAW

20

Grin All Axle, Crysatlyte H, Nine Continent,

MXUS and Other 205mm DD Motors

23

Magic Pie 3, Other 273mm DD Motors, RH212

26

Bafang BPM, Bafang CST

40

Bafang G01, MXUS XF07

44

Bafang G02, G60, G62

50

Shengyi SX1/SX2

72

eZee, BMC, MAC, Puma, GMAC

80

Bafang G310, G311

88

Bafang G370

112

For motors not listed, either open the motor to count the magnets pairs (and gear

ratio), or count the number of Hall cycles that take place when you manually turn

the wheel one revolution. You can monitor the number of Hall transitions via the

“Dashboard” tab of the software suite.

Once the “kV” and the “Number of Pole Pair” values are entered, launch the

“Static Test.” This test will produce three short buzzing sounds, and determine

the inductance and resistance of the motor windings. The resulting values will be

shown on the screen.

Next, launch the “Spinning Motor Test” which will cause the motor to rotate at

about half speed for 15 seconds. During this test, the controller will determine the

actual kV winding constant for the hub, as well as the pinout and timing advance

of the Hall sensors if they are present. If the motor spins backwards during this

test, check the box “Flip Motor Spin Direction on Next Autotuning?” and relaunch

the “Spinning Motor Test.”

During the spinning test, the

Frankenrunner

will start the motor in sensorless

mode. If the motor fails to spin and just starts and stutters a few times, adjust the

sensorless starting parameters as described in section 5.5, “Tuning the

Sensorless Self Start,” until the motor is spinning steadily. If the spinning test

detects a valid Hall sequence, the final screen will show the hall offset, and that

the “Position Sensor Type” is “Hall sensor start and sensorless run.”

-11-