Frankenrunner User Manual

Rev 1.0

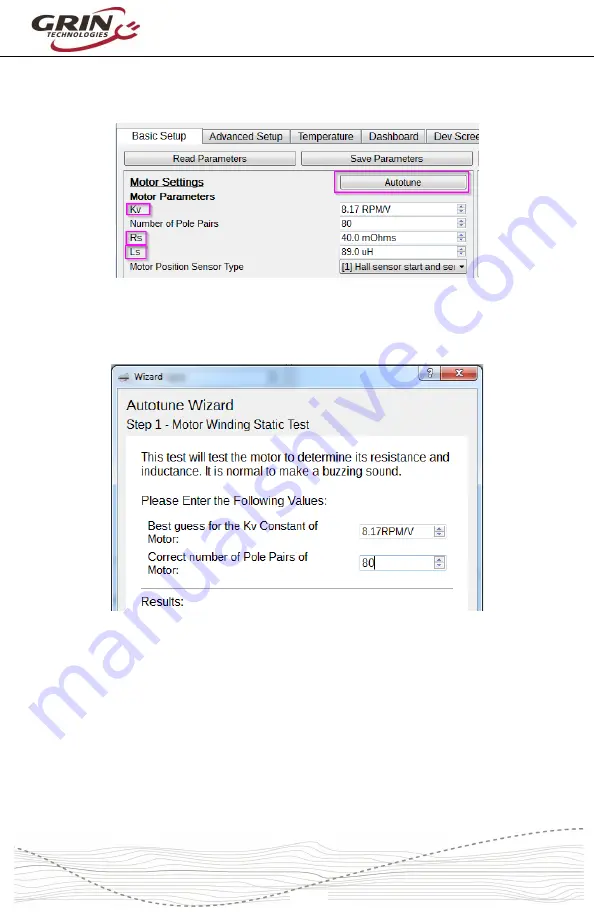

The Autotune routine can automatically detect motor parameters like the motor

speed constant (kV), resistance of one motor phase to neutral (Rs), and the

inductance of motor phase to neutral (Ls).

The start of the Autotune process asks for your best guess of the motor’s kV in

rpm/V, as well as the number of pole pairs in the motor. The firmware uses these

initial parameters for determining the test current frequency.

The Autotune routine will usually work fine even if your initial guess for the kV

value is incorrect. Most ebike hub motors fall within 7-12 rpm/V and an initial

guess of 10 will usually work.

The effective pole pairs is a count of how many electrical cycles corresponds to

one mechanical revolution of the motor and must be set correctly. The

Frankenrunner

needs this information to correlate it’s electrical output frequency

with the wheel speed. In a direct drive (DD) motor, it is the number of magnet

pairs in the rotor, while in a geared motor you need to multiply the magnet pairs

by its gear ratio. The following table lists the effective pole pairs for many

common motor series.

-10-