EVO205D SAFE / SURE-Trak 5. OPERATION

5-3

©GreenMech

Ltd

5-3

03/22

5.4 Blockages

Stop engine and REMOVE key to secure place.

Check that flywheel clutch is disengaged (See 5.9).

CAUTION! Chipped material is inflammable. Expect large volume and prevent from falling

into engine compartment. All material must be removed.

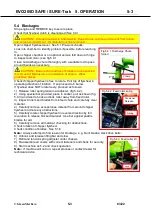

Open chipper flywheel cover. See 5.1 Pre-work checks.

Look into chamber to identify problem if possible, before reaching

in.

Open chipper chamber or on optional version fold down at hinge

to inspect and clear. (see fig 5.4.1

Clean out discharge chute thoroughly with a suitable rod to pass

around bends as necessary.

CAUTION!

Beware sharp edges of blades and unexpected

movement of flywheel due to resistance of engine. Wear

protective gloves.

Check if chipper flywheel is free to rotate. Pull top of flywheel in

operating direction

of rotation. If so proceed to 6 below.

If flywheel does NOT rotate freely, proceed as follows:

1) Release roller spring tension at adjuster. (fig 5.4.2).

2) Using special bar provided, place in socket, pull as shown (fig

5.4.3) and twist to hook and lock roller away from fixed roller.

3) Inspect rollers and blades from infeed chute and carefully clear

material.

4) Carefully remove excess loose material from around chipper

flywheel and note any obstructions.

5) Carefully rotate chipper flywheel in reverse direction by full

revolution to release blocked material. Use bar against paddle

blades for aid.

6) Carefully remove all material, checking for obstructions.

Check rotation of chipper flywheel.

Check condition of blades. See 5.1.6

Note:

Always attempt to find reason for blockage. e.g. blunt blades, slack drive belts.

6) Unhook and release lifting bar and stow.

7) Refit and tension spring adjuster under chassis

8) Re-assemble all covers with correct fasteners and check for security.

9) Start machine as 5.2 and check operation.

Note:

If machine will not run, repeat process or contact dealer for

technical advice.

Fig 5.4.3 Feed roller lift

Bar

Lock

Fig 5.4.2 Feed roller spring

Tensioner

Release

Spring

Fig 5.4.1 Discharge Chute

folded

Clamp