EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-4

©GreenMech

Ltd

6-4

03/22

6.7 Disc Blade Cleaning - Replacement

Blade design permits relocation in at least two rotated positions before regrinding or replacement is required.

1 Check engine is switched off, and start key removed.

2 Raise engine cover, and check any rotation has stopped.

CAUTIONS for Blade cleaning

•

Blades have sharp edges. Wear protective gloves.

•

Flywheel paddles and vanes create shearing and trapping points at

edges of exposed housing. Do not place hands or fingers on or

near flywheel and housing edges.

•

Flywheel rotation is resisted by engine compression in either

direction. Beware unexpected movement when manually rotating

flywheel between blade positions.

•

Tools can slip if not fully engaged. Clean fasteners thoroughly

before applying tools.

•

Ensure flywheel is prevented from rotating when applying force to

tools on blade fasteners.

Follow procedure as on symbol instructions on machine (Section 3.8):

1) Wear protective gloves.

2) Remove flywheel cover bolts.

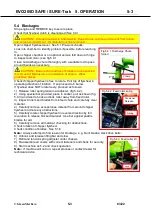

3) Using discharge chute handle as a lever, swing back cover on to stop to expose flywheel and blades. (fig 6.7.1).

4) Locate and retract flywheel locking pin, and carefully turn flywheel until locking pin engages hole (2 positions) in

flywheel to prevent movement).

5) Thoroughly clean debris from nut faces and bolt head socket.

6) Using socket tool, loosen nut anticlockwise. Support blade bolt with hexagon key as required and remove blade

and fasteners (fig 6.7.2).

7) Thoroughly clean debris from flywheel blade housing and all components to be replaced.

Inspect condition of

nuts and bolts and replace if any signs of wear. (Fig 6.7.3

and fig 6.7.4)

8) Replace blade with Nord-Lock washers ensuring that

flywheel is blocked for opposite rotation. Tighten to

correct torque: 200Nm.

Retract locking pin and carefully rotate to next blade and

repeat next blade removal (from 4 above) until all blades

cleaned and replaced securely.

9) Replace all covers.

10) Check all covers are secure.

11) Replace key to start machine.

CAUTION! Blades must only be sharpened by

grinding angled back face on a bench grinder. Grinding of

front face will upset gap, which is factory set. Do not

sharpen with hand held equipment

.

All blades must be sharpened in “sets” with equal amounts

removed to maintain balance. See 6.24

Note. If any blades are worn below flat annular section a complete set should be replaced.

Fig 6.7.3 Blade fastening assembly

Washer pair

Fig 6.7.4 Nord-Lock washer pair

Note fewer teeth facing each other

Fig 6.7.2. Flywheel and blades

Fig 6.7.1 Chipper flywheel cover

Locking Pin

Cover locating

bolts (removed)

Grease nipple