Indirect Gas-Fired Heat Modules

14

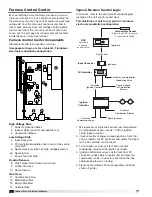

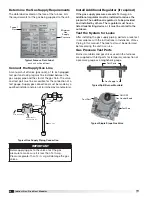

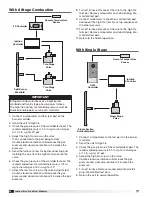

Connect the Supply Gas Line

A manual shut off valve (gas cock), a 1/8 inch plugged

test port and a drip leg must be installed between the

gas supply pipe and the start of the gas train. The valve

and test port must be accessible for the connection of a

test gauge. Supply gas connections must be made by a

qualified installer and are not furnished by manufacturer.

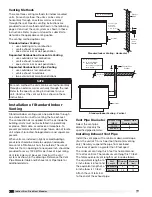

Determine the Gas Supply Requirements

The data label located on the face of the furnace lists

the requirements for the gas being supplied to the unit.

Ground

Joint

Union

8 in. Trap

Gas to

Controls

From Gas Supply

Bleeder Valve or

1/8 in Plugged Tap

Gas Cock

Typical Gas Supply Piping Connection

Type of

Gas

Minimum

Gas

Supply

Pressure

Typical Furnace Data Label

each unit will be different

IMPORTANT

Before applying gas to the valves, test the gas

pressure to make sure it is less than 14 in. wg.

Pressures greater than 14 in. wg will damage the gas

valves.

Install Additional Regulator (if required)

If the gas supply pressure exceeds 14 in. wg, an

additional regulator must be installed to reduce the

pressure. The additional regulator is to be provided

and installed by others. The regulator must have a

listed leak limiting device or it must be vented to the

outdoors.

Test the System for Leaks

After installing the gas supply piping, perform a leak test

in accordance with the instructions in

Installation of Gas

Piping

in this manual. The leak test must be performed

before placing the unit in service.

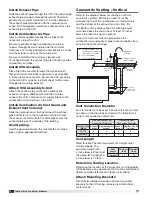

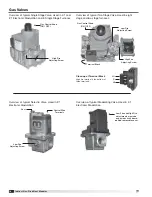

Gas Pressure Test Ports

Burner manifolds and gas valves used in the furnaces

are supplied with test ports for temporary connection of

a pressure gauge or a magnehelic gauge.

Gas Supply In

Typical Split Burner Manifold

Test Ports

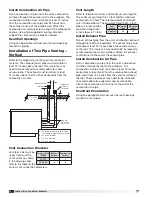

Typical Single Stage Gas Valve

Test Port

Test Port

ON / OFF

Gas Control Knob

®