Indirect Gas-Fired Heat Modules

18

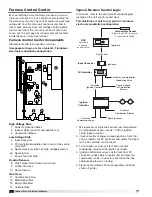

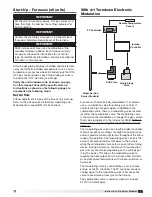

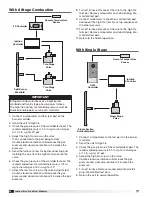

At start-up, remove the cover from the circuit board

housing by loosening the two Phillips head retaining

screws. Identify Button #1 and Button #2 and also

locate the LED indicator light.

Send the furnace to High Fire by following the

instructions below:

• Set the regulator screw on the combination valve

as high as it goes — all the way in.

• Set the High Fire set point on the modulating

valve to 3.5 in. wg for natural gas or 10.0 in. wg

for LP gas.

• Set the Low Fire set point on the modulating gas

valve at 0.3 in. wg for natural gas or 1.0 in. wg for

LP gas.

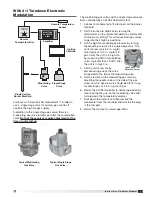

The modulating valve has four electrical connections

on-board. Two are for the 24 VAC needed to power

the valve and two are for the input signal from the FX

controller. The location of the 24 VAC power source

varies, see the unit-specific wiring diagram. The input

signal that causes the modulating valve to change gas

volume is always provided by the FX controller and

varies from 2 - 10 VDC.

When a call for heat is provided to the FX controller,

the controller will first provide a 10 VDC signal to the

modulating valve so that it will always start in a high fire

condition. After ignition, the controller will change its

output signal, causing the volume of combustion gas to

be reduced to as little as 25% of full flow (4:1 turndown)

based on demand.

Adjust High Fire and Low Fire Settings

EXA Modulating Gas Valve

(with cover removed)

Terminals 3 & 4

(power)

Button #2

LED Light

Button #1

Terminals 1 & 2

(signal)

NOTE

Before setting the modulating valve, make certain the

combination valve is set to the maximum setting. Turn

the regulator screw all the way in.

Modulating Valve High Fire Setting

1. Connect a manometer to the test port on the burner

manifold.

2. Press and hold button #1 until the LED lights solid

red. Release the button. Observe the gas pressure

on the manometer.

3. Adjust the modulating

valve by pushing

button

#1 to increase the

pressure

or by pushing

button #2 to decrease

the pressure

.

4.

Save the High Fire setting by simultaneously

holding down buttons #1 and #2 until the LED

turns off.

If the new setting is not saved within five

minutes, the modulating valve will default back to its

last saved setting.

Modulating Valve Low Fire Setting

1. With a manometer installed at the burner manifold

test port, press and hold down button #2 until the

LED blinks red. Release the button. Observe the gas

pressure on the manometer.

2. Adjust the Low Fire

setting by pushing

button #1 to increase

the pressure

or by

pushing

button #2 to

decrease the pressure

.

3.

Save the Low Fire setting by simultaneously

holding down buttons #1 and #2 until the LED

turns off

. If the new setting is not saved within five

minutes, the Modulating Valve will default back to its

last saved setting.

Restore normal operation and shut off the furnace.

Reinstall the cover on the modulating valve, remove the

manometer and reinstall the plug in the manifold test

port.

NOTE

During the adjustment process, each push of either

button will increase or decrease the pressure in steps.

Holding down either button auto-steps and eliminates

the need to repeatedly push the button. Use this

feature to rapidly increase or decrease the gas flow.

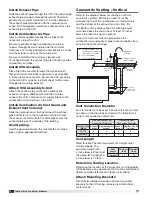

High Fire Settings

Natural Gas

3.5 in. wg

LP Gas

10.0 in. wg

Low Fire Settings

Natural Gas

0.3 in. wg

LP Gas

1.0 in. wg

®