Indirect Gas-Fired Heat Modules

21

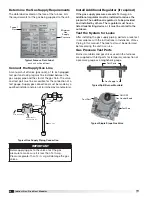

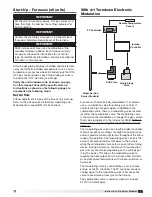

1. Connect a manometer to the test port on the burner

manifold.

2. Send the unit to high fire.

3. Check the gas pressure at the manifold test port. The

recommended pressure is 3.5 in. wg for natural gas

or 10.0 in. wg for LP gas.

4. Adjust the high fire screw on the valve.

Counterclockwise rotation will decrease the gas

pressure and clockwise rotation will increase the

pressure.

5. Send the furnace to low fire by disconnecting and

isolating the wire from the high fire terminal on the

valve.

6. Check the gas pressure at the manifold test port. The

recommended low fire manifold pressure is 7/8 in.

wg for natural gas or 2.5 in. wg for LP.

7. Adjust the low fire screw on the valve.

Counterclockwise rotation will decrease the gas

pressure and clockwise rotation will increase the gas

pressure.

8. Turn off furnace. Reconnect the wire to the high fire

terminal. Remove manometer and reinstall plug into

manifold test port.

9. Return the unit to normal operation.

IMPORTANT

Confirm that the discharge air sensor is installed in the

duct at least three duct diameters downstream of the

furnace.

Single Section

Burner Manifold

Two Stage

Valve

Remote Temperature

Sensor

A350

Controller

A350

JOHNSON

CONTROLS

Ignition

Controller

With 2 Stage Combustion

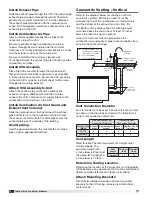

With Combination Turndown

Configurations

There are several different turndown options that may

be used in the units that are simply combinations of

basic configurations.

In all cases, all gas valves must be set for high fire

and low fire as part of the Start-Up process.

Inspect the furnace(s) and verify the type of valve(s) and

manifold used. Refer back to the previously described

configurations and find the one that most closely

matches the valve and manifold types present in this

unit. Adjust the high fire and low fire settings on all

valves before placing the unit in service.

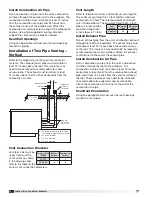

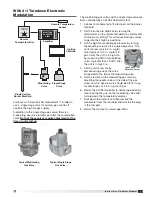

p

Sensor

A350

JOHNSON

CONTROLS

A350

Controller

S350

JOHNSON

CONTROLS

S350

Controller

OR

OR

Eight Stage

Furnace

Single Stage

Furnace

Provides

16 Stages

Two Stage

Furnace

Two Stage

Furnace

Provides

4 Stages

Single Stage

Furnace

Single Stage

Furnace

Provides

2 Stages

Electronically

Modulated

4:1 Turndown

Furnace

Single Stage

Furnace

Provides

8:1 Turndown

FX Controller

Lead Furnace

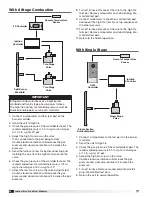

A modulating furnace can also be combined with a

single stage furnace. Both furnaces are then controlled

by an FX controller.

In some cases, two furnaces may be installed in parallel

in one ventilating unit. In that case, the turndown is the

same as just a single furnace.

®