Section 11: Servicing

Page 45

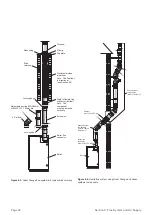

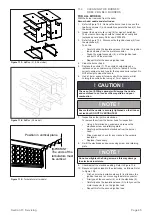

Figure 11-1:

Baffles (21 & 26 model)

Figure 11-2:

Baffles (36 model)

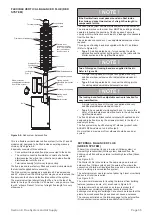

IMPORTANT:

The ends of the

turbulators must

be vertical

Position in vertical plane

Figure 11-3:

Turbulators (all models)

11.4

CLEANING THE BURNER:

RDB2.2 BG BLU BURNERS

FOR ALL MODELS

With the burner removed from the boiler:

Burner head, nozzle and electrodes:

1. Refer to Figure 10-3. Remove the burner head. Loosen the

two fixing screws (1) and carefully separate the head (2) from

the burner.

2. Inspect the burner collar o-ring (8) for signs of perishing.

The burner collar o-ring should be inspected annually and

replaced as necessary. Part code: Z3008878.

3. Refer to Figure 10-3. Disconnect both ignition leads (4) from

the electrodes (5)

To do this:

•

Carefully slide the insulation sleeve (3) down the ignition

lead and away from the metal connector.

•

Grasp the metal connector (4) - not the ignition lead -

and pull it off the electrode.

•

Repeat this for the second ignition lead.

4.

Clean the burner head.

5. Replace the nozzle (7). The nozzle should always be

replaced on an annual service. Refer to Table 2-3 for the

correct nozzle size and type for the required boiler output. Do

NOT attempt to clean the nozzle.

6.

Use a 16 mm spanner to remove/re-fit the nozzle, whilst

holding the nozzle holder using a 17 mm spanner.

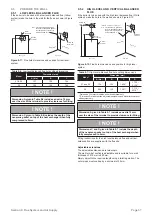

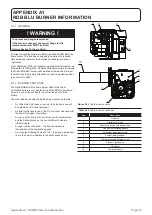

! CAUTION !

The use of an ill-fitting spanner will damage the nozzle

and could lead to an incorrect flame pattern and poor

combustion.

! NOTE !

Ensure that the nozzle is securely tightened so that it does

not leak but DO NOT OVERTIGHTEN!

7.

Inspect/clean the ignition electrodes.

To remove them from the burner head for inspection:

•

Using a 3mm allen key, unscrew and remove the

electrode screw and retaining plate.

•

Carefully withdraw both electrodes from the burner

head.

•

Wipe clean and check for any cracks in the ceramic

insulation.

•

Replace if necessary.

8.

Re-fit the electrodes and secure using screw and retaining

plate.

! NOTE !

Do not overtighten the fixing screw as this may damage

the electrode insulators.

9.

Check/adjust the electrode setting. Refer to Figure 10-4.

10. Reconnect ignition leads to the electrodes, as follows. Refer

to Figure 10-3.

•

First, ensure the insulation sleeve (3) is slid down the

ignition lead and is not covering the metal connector.

•

Firmly push the connector (4) on to the electrode (5).

•

Carefully slide the insulation sleeve (3) to fully cover the

metal connector (4) on the ignition lead.

•

Repeat this for the second ignition lead.