! WARNING !

Ensure that the electrical supply has been isolated before

making any connections to the boiler.

8.1 GENERAL

Grant VortexBlue models require a ~230V 1ph 50Hz supply, which

must be protected by a 5 Amp fuse.

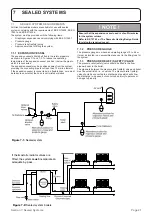

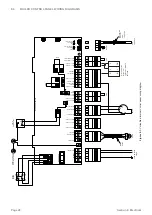

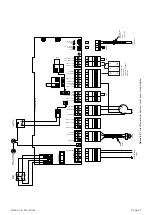

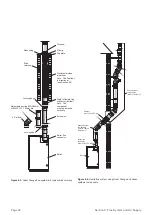

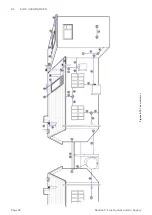

Refer to Figures 8-1 and 8-2 for control panel wiring diagrams.

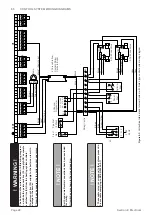

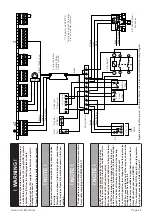

Refer to Figures 8-3 and 8-4 for typical control system wiring

diagrams for all models.

! WARNING !

The Vortex boiler contains electrical switching equipment

and must be earthed.

The supply must be fused at 5 Amp and there must only be one

common isolator for the boiler and control system, providing

complete electrical isolation.

A fused double pole switch or a fused three pin plug and shuttered

outlet socket should be used for the connection.

The power supply cable should be at least 0.75 mm

2

PVC as

specified in BS 6500, Table 16.

All the wiring and supplementary earth bonding external to

the boiler must be in accordance with the current IET Wiring

Regulations.

Any room thermostat or frost thermostat used must be suitable for

use on mains voltage.

In the event of an electrical fault after installation of the boiler, the

following electrical system checks must be carried out:

•

Short circuit

•

Polarity

•

Earth continuity

•

Resistance to earth

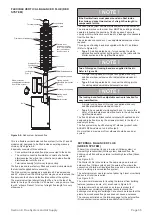

! NOTE !

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

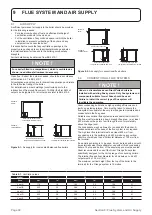

8.2

CONNECTING THE POWER SUPPLY

8.2.1 CONNECTING POWER SUPPLY, PUMP

AND CONTROL SYSTEM

The boiler requires both a switched live, from an external

programmer or control system AND a permanent live power

supply.

This permanent live supply is essential for the fan post purge

operation.

Failure to fit BOTH a switched live and permanent live may cause

damage to the burner.

! NOTE !

Do not interrupt the permanent mains supply to the boiler

with any external control, e.g. a timer, programmer, or

room thermostat.

! WARNING !

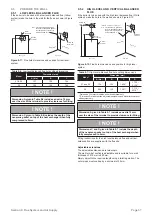

The boiler must be wired as shown in Figures 8-3 and

8-4, i.e. with both a permanent live supply AND a separate

switched live (from the heating system controls).

No permanent live supply to the boiler can result in

damage to the burner.

This will not be covered by the boiler product guarantee.

There is no facility in the Grant VortexBlue Internal and Internal

System boilers for the fitting of a plug-in timer or programmer.

A 4-core cable (3-core and earth) is required to connect the power

supply and heating controls to the boiler.

On non-system models a 3-core cable (2-core and earth) is

required to connect the circulating pump to the boiler.

For typical control system wiring diagrams, please refer to Figures

8-3 and 8-4.

! NOTE !

Ensure that the route and length of the supply and pump

cables are such that the boiler control panel can be fully

hinged down without needing to disconnect them from the

terminal block.

The procedure to connect the power supply is as follows:

1.

Lift off the boiler top front casing panel, if it has not already

been removed.

2. Loosen (do not remove) the four screws securing the control

panel to the side panels, hinge the panel forward and allow it

to drop down to gain access to the top of the panel.

3. Remove the two screws securing the terminal block cover

and lift off the cover.

4. Remove the screws securing the cable clamp and open the

clamp.

5. Route the supply cable through the hole in the rear panel

(using the grommet supplied) and up the control panel.

6.

Pass the 4-core cable through the cable clamp and connect

to the boiler control panel terminals as follows:

•

Green/Yellow to mains earth (terminal 1)

•

Grey* to mains neutral (terminal 2)

•

Brown to mains live (terminal 3)

•

Black* to switched live (terminal 19)

On non-system models - pass the 3-core cable from the

pump through the cable clamp and connect to the boiler

control panels as follows:

•

Green/Yellow to pump earth (terminal 4)

•

Blue to pump neutral (terminal 5)

•

Brown to pump live (terminal 6)

7.

Make the remaining required connections to the control

panel, as detailed in this section.

8. Secure the cable(s) in the cable clamp

9.

Place the terminal block cover in position over the terminal

block, taking care not to trap any wires and secure in position

with the two M4 screws provided.

10.

Close the hinged panel and tighten the four screws securing

the control panel to the side panels.

11. Replace the top casing panels.

12.

Ensure that all external wiring is adequately supported.

Section 8: Electrical

Page 24

8 ELECTRICAL