GMS SERIES

OM-04386

PAGE E-11

MAINTENANCE AND REPAIR

HOUSING

ASSY

HEAD

CLEARANCE

CLEARANCE

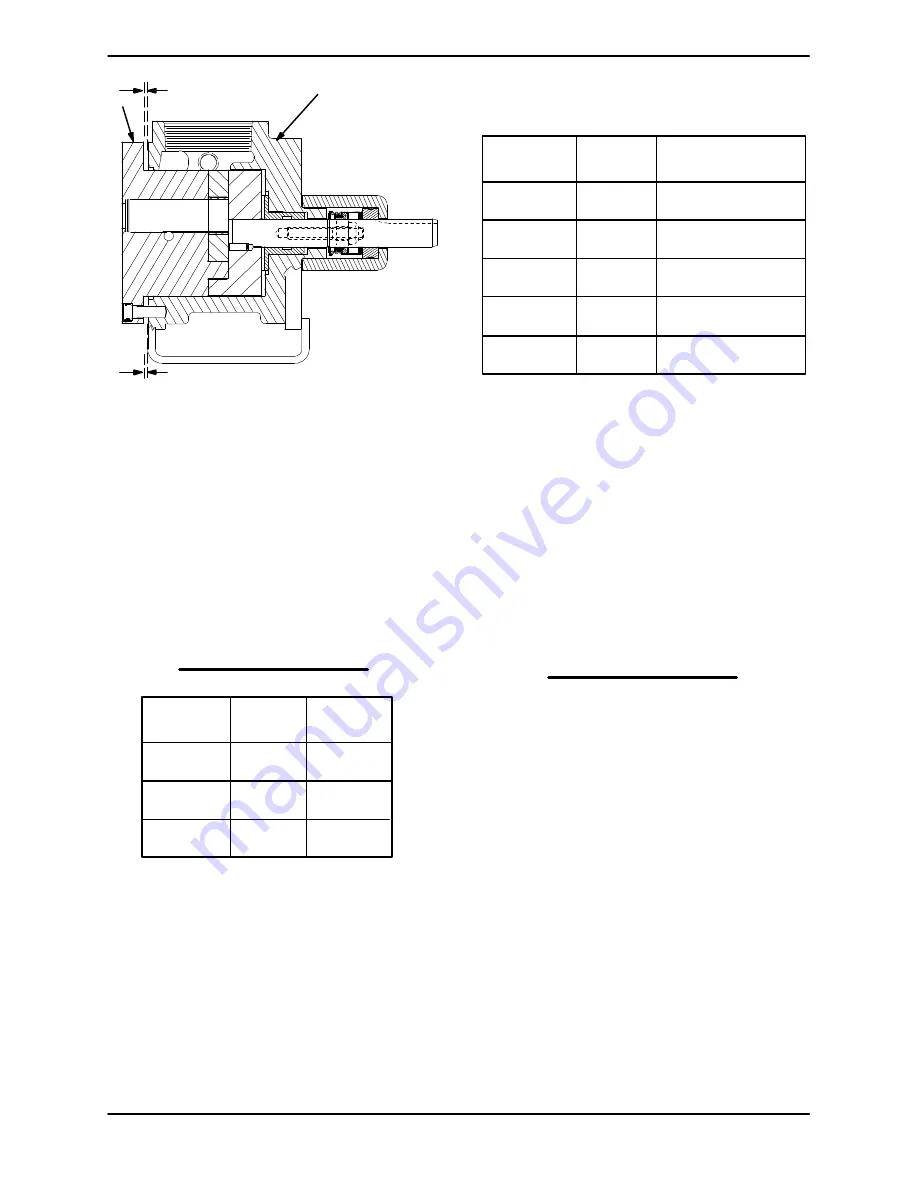

Figure E‐4.

End Clearance Adjustment

See Tables E-1 or E-2 to determine the gasket(s)

(01B) required for the viscosity and temperature of

the liquid being pumped. Remove the head from

the housing assembly and install the gasket(s).

Reinstall the head on the housing assembly (04)

and secure with the capscrews (B).

NOTE

The gasket set (01B) includes (2) 0.006 inch gas

kets and (2) 0.015 inch gaskets

and will accommo

date all standard clearances. If additional clear

ance is required, order two kits.

Notes:

For Special Applications, Consult Your Local

Gorman‐Rupp Distributor or the Factory.

Viscosities and Temperatures are Maximums.

Gasket Quantities Shown in Parenthesis.

Feeler Gauge

Reading

2500 SSU

225

_

F

(107

_

C)

0.000-0.002

0.003-0.006

0.007-0.010

(2) 0.015

250,000 SSU

300

_

F

(149

_

C)

(2) 0.015

(1) 0.006

(2) 0.015

(2) 0.006

(1) 0.015

(1) 0.006

(2) 0.015

(2) 0.015

(1) 0.006

Table E‐1.

End Clearance Gaskets

(Based on Liquid Viscosity)

35C, 35D, 35J, 35L &

35M

Rotor Trims

Feeler Gauge

Reading

Std

Rotor

Trims

0.000-0.002

0.003-0.006

0.007-0.010

0.011-0.014

0.015-0.018

(1) 0.015

(1) 0.006

(2) 0.015

(2) 0.015

(2) 0.015

(1) 0.006

(2) 0.015

(1) 0.006

(2) 0.015

(2) 0.006

Notes:

For Rotor Trim Codes Not Listed or for Special Applications,

Consult Your Local Gorman‐Rupp Distributor or the Factory.

Consult Pump Parts List For Rotor Trim Code.

(2) 0.015

(2) 0.006

(3) 0.015

(1) 0.006

(3) 0.015

(2) 0.006

(3) 0.015

(2) 0.006

Table E‐2.

End Clearance Gaskets

(Based on Rotor Trim Code)

RELIEF VALVE DISASSEMBLY

(Figure E‐6)

NOTE

If the relief valve is low pressure, it will have one in

ternal spring (10AE). If the relief valve is high pres

sure, it will have two internal springs (10AE and

10AF).

Unscrew the cap (10AN) from the bonnet (10AK)

and remove the gasket (10AP). Back off the adjust

ment capscrew (10AM) to relieve pressure on the

spring(s) (10AE and/or 10AF).

Unscrew the bonnet from the valve body (10AA).

Remove the valve (10AD) and spring(s) (10AE and/

or 10AF). The spring guide (10AH) is an O‐ring fit in

the bonnet. Remove and discard the O‐rings.

If the warning plate (10AB) must be replaced, re

move the drive screws (BM), and remove the plate.