GHC SERIES

OM-04386

PAGE B-3

INSTALLATION

To flush the pump, use an approved solvent com

patible with the liquid being pumped.

Make cer

tain that the solvent will not attack pump com

ponents, particularly seals and gaskets.

PUMP INSTALLATION

Pump dimensions are shown in the separate

Pump Specification Bulletin.

Never operate the pump without a pres

sure relief valve installed on the pump

or in the discharge piping. Make certain

that pump‐mounted pressure relief

valves are installed with their adjusting

ends toward the suction port. If bi‐rota

tional operation is required, a pressure

relief device must be provided for both

directions of flow. Operation without a

pressure relief valve or with an improp

erly installed relief valve could cause

the pump to explode, resulting in seri

ous injury or death to personnel.

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Positioning The Pump

Locate the pump as close as possible to the liquid

being pumped. Locating the pump below the liq

uid source will help self‐priming and reduce the

possibility of cavitation.

Mounting

The pump may be shipped alone, mounted on a

base, or with pump and motor mounted on a base.

Install the pump and motor on a base before

mounting the base on a foundation.

Mount the base on a foundation that will provide

permanent, rigid support for the pump, and will be

heavy enough to absorb any vibration, strain or

shock.

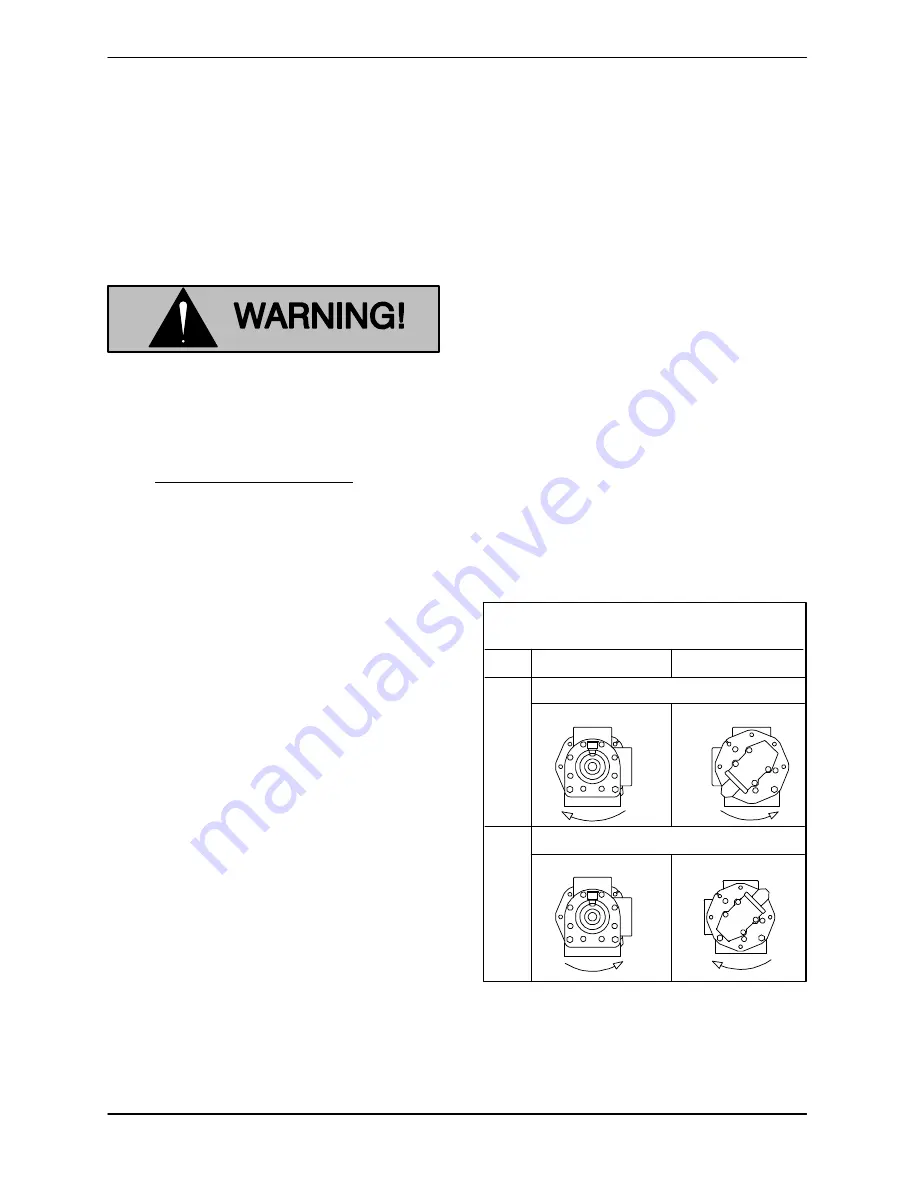

Piping

Before establishing suction and discharge lines,

determine pump port positions and rotation. Fig

ure B‐1 shows typical port positions for the stan

dard 90

housing; if you have selected a 180

housing port option, your port positions will be dif

ferent.

Begin piping layout at the pump, and work toward

the source of supply and the point of discharge.

Either hose or rigid pipe may be used to make con

nections. If rigid piping is used, install expansion

joints to protect the pump from vibration and ther

mal expansion in the piping. Do not use expansion

joints or flexible connectors to adjust misaligned

piping.

Housing Position Std. 90

Pump

(3-12 O'clock) Head Mounted Relief Valve

STD.

OPT.

Rotation Clockwise

Drive End

Rotation Counter‐clockwise

01A

D

S

S

Front End

S

D

D

D

S

Figure B‐1. Typical Port Positions & Rotation

The discharge and suction lines must be inde

pendently supported to avoid vibration and strain

on the pump. For maximum pumping capacity,

keep the lines as short and straight as possible. El