GMS SERIES

OM-04386

PAGE B-4

INSTALLATION

bows and fittings used in the lines increase friction

losses; minimize their use. Reducers used in suc

tion lines should be the eccentric type installed

with the flat part uppermost to avoid creating air

pockets.

Before tightening a connection or flange, align it

exactly with the pump port. Never pull a pipe line

into place by tightening the flange bolts and/or

couplings.

Strainers

Because of the close‐tolerance moving parts of

this pump, it is recommended that a strainer be in

stalled in the suction line. The strainer should be

large enough to prevent excessive vacuum, and

capable of operating under high vacuum without

collapsing. The net open area of the strainer

screen depends on liquid viscosity and desired

flow rate; in any case, the sum of the area of all the

holes in the screen should be three to five times the

area of the suction pipe.

Gauges

To monitor operation and assist in troubleshooting,

a vacuum gauge and a pressure gauge should be

installed on the pump.

Sealing

Even a slight leak will affect priming, head, and ca

pacity, especially in a suction lift application. Seal

all piping joints, valves and gauges with pipe dope

or teflon tape. The sealing material should be com

patible with the liquid being pumped.

Valves

To avoid air pockets, install piping valves with the

stem horizontal.

To prevent leakage during shutdown, install a shut

off valve in the discharge line, particularly on a

flooded suction application. Shutoff valves are not

recommended for suction lines.

It is

not

recommended that a foot valve be installed

at the end of the suction line. If desired to install a

foot valve, consult the factory.

When handling very hot or cold liquids, install a

pressure relief valve in any part of the system that

can be valved off or isolated; this will protect piping

against damage from liquid thermal expansion or

contraction from temperature changes during

shutdown.

Barrier Liquids for Optional Double Lipseal

In general, a barrier liquid is

always

recommended

for these seals. This requirement may be satisfied

by a simple oiler, or it may become more compli

cated based on the application. The following bar

rier liquid guidelines are offered for maximum per

formance;

1.

Select a clean, lubricating liquid that is

compatible with the pumped product

and with the pump construction (iron or

316 SST).

2.

Depending upon pump shaft speed, a

pressurized barrier liquid may not be re

quired. Consult the factory for your spe

cific application.

ALIGNMENT

Make certain that power to the drive unit

is disconnected before attempting to

connect the pump drive; otherwise, per

sonal injury may result.

NOTE

See

ROTATION

in Section C before mounting the

pump on the base.

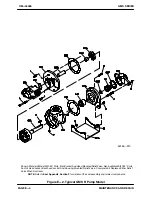

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Most couplings require a specific gap or clearance

between the driving and the driven shafts. Refer to

the coupling manufacturer's service literature.

Align spider insert type couplings by using calipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90

.