OM-04386

GMS SERIES

PAGE E-10

MAINTENANCE AND REPAIR

shaft and rotor must be replaced as an assembly.

Small scratches can be dressed with a fine file or

emery cloth. Replace the rotor/shaft assembly or

any other parts if wear or damage is extensive.

Carefully slide the rotor/shaft assembly into the

housing.

Use caution

not to scratch the I.D. of the

housing bushings (04B).

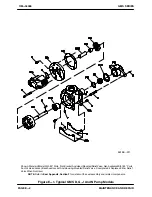

Head/Idler Kit (01/02)

If the idler pin (01AB) was removed, apply Loctite

Pipe Sealant with Teflon No. 565 or equivalent com

pound to the I.D. of the idler pin bore in the head

(01A). Position the pin in the head with the cham

fered side toward the head and the milled flat side

facing the crescent. (If the pin is stepped, position it

with the large chamfered end toward the head.)

Use an arbor (or hydraulic) press to press the pin

into the head until it bottoms out.

NOTE

When properly installed, the pin will be positioned

0.010 inch below the surface of the crescent.

Lightly oil the I.D. of the idler (02A), and use an ar

bor (or hydraulic) press to install the idler bushing

(02B) in the idler. The bushing should be centered

at both ends of the idler.

Place the head (01A) on a flat surface. Lightly oil the

idler bushing (02B) and pin (01AB); install the idler

assembly (02) on the pin. Spin the idler to make

certain that it moves freely on the pin.

See

SETTING END CLEARANCE

and calculate

the number and thickness of gaskets (01B) re

quired for your application and hydraulic pump

size. Position the gasket(s) against the head, and

slide the head into the housing assembly. Rotate

the head (01A) until the groove in the head

matches the groove in the housing. Secure the

head to the housing with the capscrews (B).

Seal Installation (05)

The seal assembly (05) is available in a variety of

configurations. Check the

Parts List

furnished with

your pump to identify the seal, then refer to

Seal

Appendix,

Section F

, for installation of the seal

and related components.

Gland Installation (04N)

NOTE

The seal assembly (5) must be installed with the

gland. Check the

Parts List

furnished with your

pump to identify the seal, refer to

Seal Appendix

,

Section F

for installation of the seal and related

components, then proceed as follows with pump

reassembly.

Install the gland gasket (05P). With the seal and re

lated components installed, slide the gland (04N)

over the rotor shaft assembly (03A) and secure it to

the housing (or backhead) with the nuts (D).

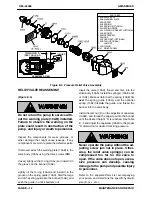

Foot Bracket Kit (08, R Size Only

)

Secure the foot bracket (08A) to the head (01A)

and backhead assembly (06A, Figure 2) with the

hardware (B and D).

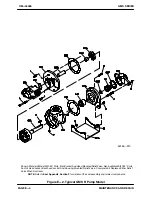

SETTING END CLEARANCE

(Figures E‐1 and E‐4)

The end clearance between the head (01AA) and

the face of the rotor (03A) should be checked and

adjusted as required as part of a regular preventive

maintenance schedule, when performance drops

or the pump is disassembled.

NOTE

The end clearance is established

without

the head

gasket set (01B) in place.

Slide the head assembly into the housing assem

bly. Rotate the head (01AA) until the groove in the

head matches the groove in the housing. Secure

the head to the housing with the capscrews (B).

The head

must

be drawn completely tight against

the housing to establish the correct end clearance.

Use a feeler gauge to measure the clearance be

tween the front of the housing assembly and the

back of the head as shown in Figure E‐4.