8

SYSTEM EVACUATION

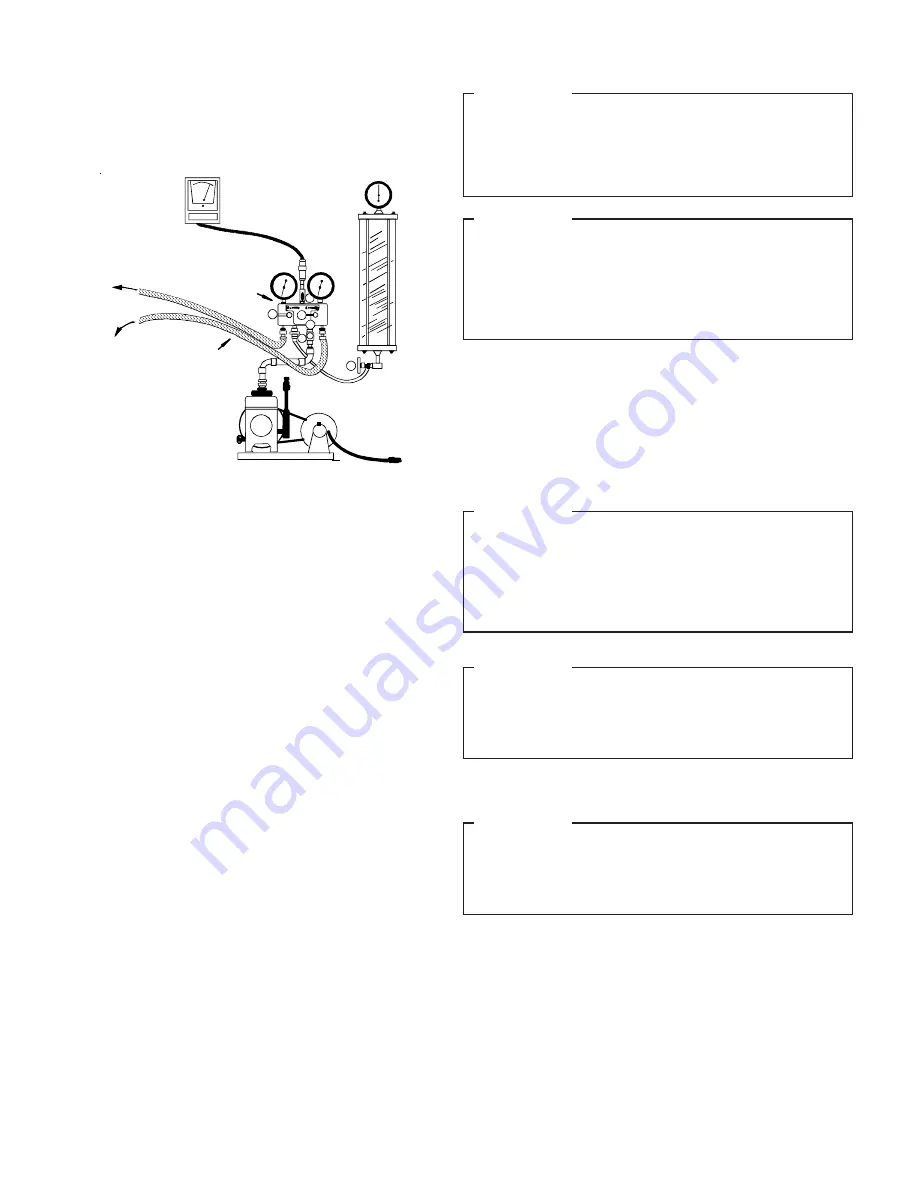

1.

Connect the vacuum pump, high vacuum manifold set with

high vacuum hoses, thermocouple vacuum gauge and

charging cylinder as shown. Begin with all valves fully closed.

2.

If service dill valves are used for evacuation, use a core

remover to lift the valve core. It provides greater efficiency.

3.

Confirm proper pump and gauge operation. Open the shutoff

valve that leads to the high vacuum gauge manifold. Start

the pump. When the compound gauge (low side) reading

drops approximately 29 inches of vacuum, open the valve to

the thermocouple vacuum gauge and evacuate until the

gauge reads 250 microns or less.

4.

Close the valve to the thermocouple vacuum gauge. This

avoids potential gauge damage from “pegging the meter”.

5.

Open the high and low side valves on the gauge manifold.

Keeping the valve on the charging cylinder closed, open the

valve on the gauge manifold that leads to the cylinder.

6.

Evacuate the system to about 29 inches Hg as measured by

the compound (low side) gauge.

7.

Open the valve to the thermocouple vacuum gauge. Evacuate

until the gauge reads 250 microns or less.

8.

Close the valve to the vacuum pump. Wait five minutes, then

check the pressure on the thermocouple vacuum gauge:

¾

If the pressure is not more than 1500 microns, the system is

leak-free and properly evacuated. Proceed to Step 9.

¾

If the pressure rises, but holds at about 5000 microns,

moisture and non-condensibles are still present. Open the

valve to the vacuum pump, and go back to Step 7.

¾

If the pressure rises above 5000 microns, a leak is present.

Go back to “Leak Testing” section above

9.

Close the valve to the thermocouple vacuum gauge. Close

the valve to the vacuum pump. Shut off the pump.

A. LOW SIDE VALVE

B. HIGH SIDE VALVE

C. VACUUM PUMP

D. THERMOCOUPLE GAUGE

E. MANIFOLD GAUGE

F. CHARGING CYLINDER

C

A

B

E

D

HIGH VACUUM PUMP

LARGE DIAMETER

BRAIDED VACUUM

HOSES

TO

RELATED

GAUGE

PORTS OF

COND. UNIT

HIGH VACUUM

MANIFOLD

LOW SIDE

GAUGE

HIGH SIDE

GAUGE

DIAL-A-CHARGE

CHARGING CYLINDER

THERMOCOUPLE

VACUUM

GAUGE

F

PRELIMINARY CHARGE ADJUSTMENT

See the wiring diagram or outdoor unit specification sheet

to determine if this unit has a crankcase heater. If it does,

you must connect electrical power to the unit for four hours

before operating the compressor. Failure to do so could

result in compressor damage.

During all installation and service work, follow all regula-

tions of the Environmental Protection Agency. (This sys-

tem uses R-22 - an HCFC [Hydrogenated Chlorofluoro-

carbon].) It is a violation of EPA regulations to discharge

HCFC into the atmosphere and doing so may result in

fines or other penalties.

Use a male hex head wrench (5/16" for liquid) to carefully open

the liquid valve stem on the unit. Use a service wrench or cres-

cent wrench to open the suction ball valve. The valve is fully

open with a 90

°

turn (i.e. the stem is inline with the valve flow

direction).

The outdoor unit is factory charged with 2 lb. R-22.

IMPORTANT:

IMPORTANT:

IMPORTANT:

Use only refrigerant which is certified to meet ARI Stan-

dard 700. Used refrigerant may cause compressor dam-

age, and will void the warranty. (Most portable machines

cannot clean used refrigerant well enough to meet this ARI

Standard.)

IMPORTANT:

When adding additional refrigerant to a system, add only

refrigerant vapor (not liquid) through the suction valve (low

side) on the outdoor unit. Any other practice may cause com-

pressor damage.

FINAL CHARGE ADJUSTMENT

IMPORTANT:

Never operate the compressor with the suction valve closed

to “test the compressor’s pumping efficiency”. In some cases,

this can result in serious compressor damage and loss of

warranty coverage.

For 25’ of line set the 7-1/2 ton charge is approximately 19 lb.

For 25’ of line set the 10-ton is approximately 26 lb. of R-22.

DO

NOT start

with these amounts

.

Figure 11.