29

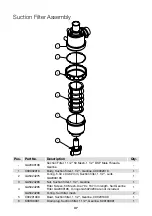

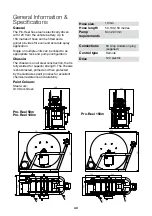

Suction Filter

It is essential to maintain all filters, and filter

screens, in good condition. Filter screens that

are not regularly cleaned can severely impede

the flow and thus affect delivery pressure.

If the screen is in any way damaged, it can

allow foreign material into the pumping

system which can result in damage to the

pump, lines, valves and nozzle tips. If the

screen is not properly fitted, it can allow air

into the pumping lines which will reduce the

performance of the pump. The filter screen

should be cleaned after every spraying

operation. The best way to clean the filter

screen is with a soft brush or compressed air

after washing the entire chemical residue from

the pump.

SAFETY SHUT-OFF VALVE

The safety shut off valve enables the filter bowl

to be removed while automatically shutting off

the supply line to the filter. As the filter bowl

is removed together with the bowl cap, the

valve plunger seats so as to seal off the filter

from the supply line. Replacing the filter bowl

unseats the valve plunger and thus opens the

supply line to the filter.

SUCTION FILTER CLEANING

WARNING:

Appropriate PPE must be worn

when cleaning filters.

1.

Ensure the pump is turned off.

2.

Carefully unscrew filter nut and remove

bowl and avoid contact with residual

chemical.

3. Remove screen and clean (with a soft

brush or compressed air).

4. Check for damage to screen, bowl,body

and O-ring.

5. Place screen back in position.

6. Make sure O-ring is in position for proper

seal.

7. Replace bowl and screw nut on. Do not

over-tighten nut.

Filling

When filling the sprayer it is necessary to use

an external water source.

WARNING

: Operators must wear the

appropriate PPE.

The following steps should be followed when

filling the tank:

1. With sprayer mounted on the vehicle, park

on level ground.

2.

The pump should be turned off.

3. Remove the tank lid.

4. Add 20% of the tanks volume of clean

water, or more, if the chemical is in a

denser form e.g. powder.

5. Add chemical as required. Some agitation

will take place as the rest of the water is

added.

6.

Use external water source to fill main tank

(Do not exceed the tank capacity).

7. Replace the tank lid and ensure that it is

secure prior to switching on pump. You are

now ready to use the sprayer.

WARNING

: When filling tank with water, 1

litre of water will add 1 kg of weight. Some

chemicals have a higher density than water

and will weigh more per litre. Therefore, it

is the operators responsibility to ensure the

loaded weight of the sprayer does not exceed

the towing and / or carrying capacity of the

vehicle.