19

Sprayer Transport

Make sure the vehicle has sufficient lifting and

braking capacity to carry the sprayer.

All relevant transport regulations must be

adhered to when transporting the sprayer i.e.

speed regulations, oversize signs, flashing

light, etc. It is the operator’s responsibility to

know the relevant regulations. Make sure the

sprayer is securely attached to the vehicle as

shown below.

CAUTION:

Take care when reversing the

vehicle with the sprayer attached. If driver

visibility is restricted use another adult, with

a clear view to the rear of the sprayer, to give

reversing directions.

CAUTION:

It is the operator’s responsibility to

know the tare weight and gross weight of the

sprayer.

Contact Goldacres dealer to ascertain a more

precise tare weight for your sprayer if unsure.

If any alterations are made to the sprayer, it is

the operator’s responsibility to know the tare

weight and the gross weight of the modified

sprayer at all times.

Vehicle Mounting

The Traymount sprayers have been designed

for carrying by a suitably rated vehicle.

WARNING:

Read and understand the vehicle

mounting safety section at the beginning of

this manual.

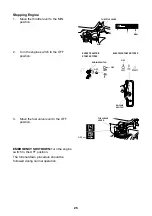

1. Remove from pallet (if attached) and

position on a solid, flat surface.

2. Use a forklift, or other suitably rated lifting

device, to lift the sprayer to a height

suitable for the vehicle. Use support legs

to fix the unit at this height.

3. Mount the Tray Mount to your vehicle.

Use the reverse of the procedure above to

remove the Tray Mount from the vehicle.

First Time Start Up

CAUTION:

Before using this equipment with

a chemical mix, read and understand, the

instructions on the chemical label. A first time

start up procedure should be carried out as a

water test only without any chemical present

in the tank.

1. Inspect the sprayer to ensure there is no

damage or wear which could lead to injury,

further damage or reduce its performance.

2. Check all bolts and nuts to make sure they

are tight and secure.

3. Carry out scheduled lubrication.

4. Make sure the sprayer is securely attached

to the vehicle

6. Ensure all filters and nozzles are clean.

7. Fill main tank with approximately 10% of

total tank volume of fresh water.

8. Move the bypass unloader lever on the

pressure control unit outwards to allow the

engine to start with no load.

9. Start the engine at the lowest revs

possible and then gradually increase

revs until the pump reaches your desired

operating speed.

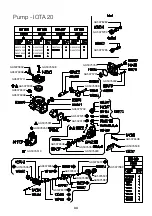

IMPORTANT:

The reduction gearbox operates

at 6:1 ratio from engine to pump. The spray

pump speed should not exceed 540 RPM.

Engine speed should not exceed 3250 RPM.

10. Move the bypass unloader lever inwards to

allow spray pressure to reach the gunjet.

Ensure that the spray gun outlet valve on

the pressure control unit is open.

11. Check spray gun operation. If there are

irregularities, clean the nozzle or tighten

fittings as necessary.

12. Check all other components are operating

correctly and make any adjustments as

necessary.

NOTE

: For optimal sprayer set-up, the

operator needs to be aware of the correct

nozzle and correct speed at which to travel

when spraying. For this information, refer

to the TeeJet catalogue and your chemical

manufacturer’s information for determining

appropriate spray rates or consult an

agronomist for further help.