GEK-99044

C-1

Appendix C. Considerations for Operation

APPENDIX C CONSIDERATIONS FOR OPERATION

!

Voltage: 120 VAC and 240 VAC ±15% auto range seeking.

!

Frequency: 48 to 65 Hz.

!

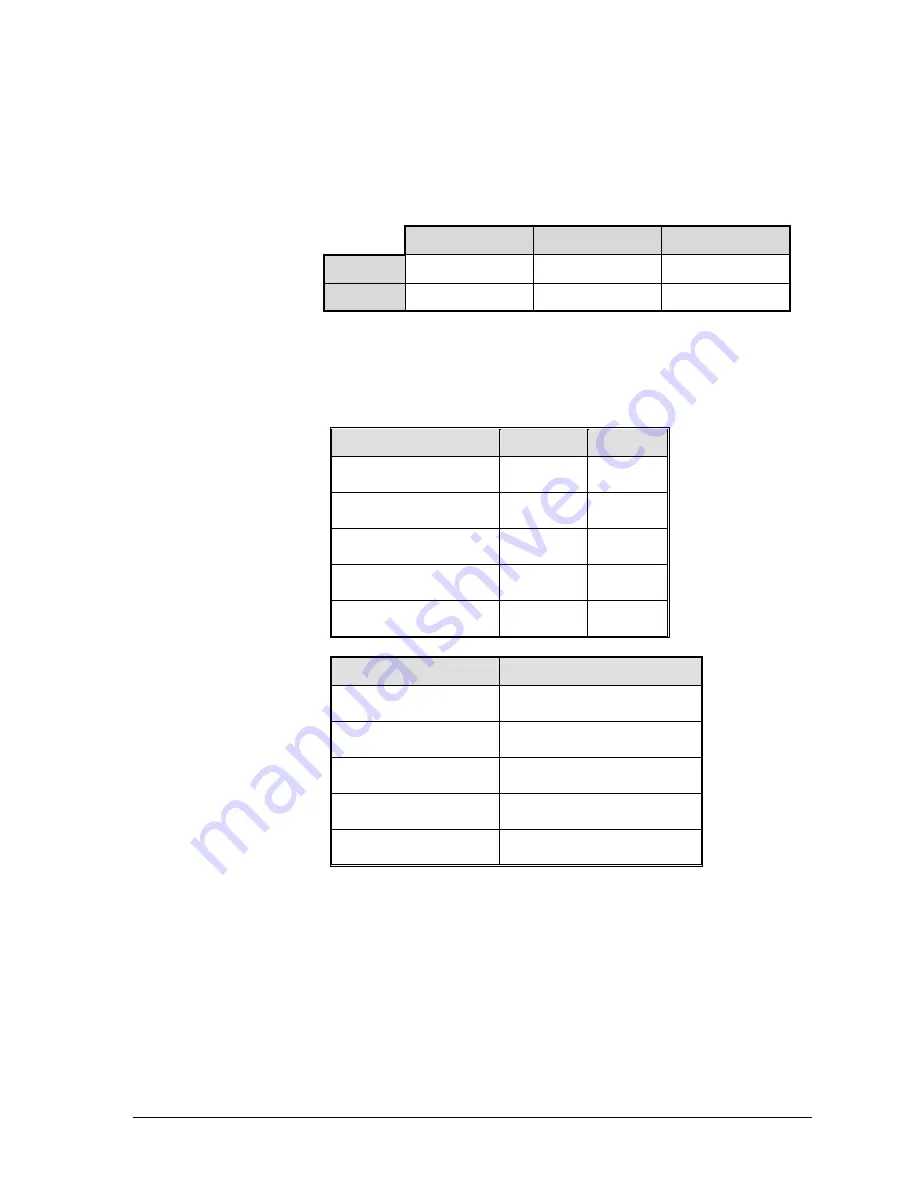

Power Consumption:

500-LPM

1000-LPM

1800-LPM

Idle

35 Watts

35 Watts

50 Watts

Printing

213 Watts

350 Watts

674 Watts

Dissipated Power (maximum):

500-LPM 400 Watts = 1370 BTU/hour

1000-LPM 524 Watts = 1795 BTU/hour

1800-LPM 1167 Watts = 3997 BTU/hour

!

Weight:

Cabinet Model

Unboxed

Boxed

5050/5100 (55 dBa)

175 lbs.

97.3 kg

220 lbs.

99.7 kg

5050/5100 (50 dBa)

295 lbs.

133.8 kg

340 lbs.

154.2 kg

5050/5100 (60 dBa)

169 lbs.

214 lbs.

76.8 kg

97.3 kg

5180 (55 dBa)

320 lbs.

145 kg

404 lbs.

138 kg

5180 (52 dBa)

420 lbs.

191 kg

462 lbs.

210 kg

!

Overall size:

Cabinet Model

Physical Size (HxWxD)

5050/5100 (55 dBa)

42 x 26.5 x 25 in.

1077 x 679 x 635 mm

5050/5100 (50 dBa)

42 x 27 x 29 in.

1077 x 686 x 737 mm

5050/5100 (60 dBa)

39 x 26.6 x 25 in.

991 x 679 x 635 mm

5180 (55 dBa)

48 x 29 x 25 in.

1219 x 737 x 635 mm

5180 (52 dBa)

42 x 30 x 29 in.

1080 x 760 x 725 mm

An additional 20 inches (50.8cm) of clearance is required in front of

the printer to open the pedestal door.

An additional 22 inches of clearance is required in the rear of the

5050/5100 (50 dBa) Cabinet Model printer to open the rear cabinet

door.

An additional 20 inches of clearance is required in the rear of the

5180 (52 dBa) Cabinet Model printer to open the rear cabinet door.