Jaguar IV User Manual

The Control Panel 3-7

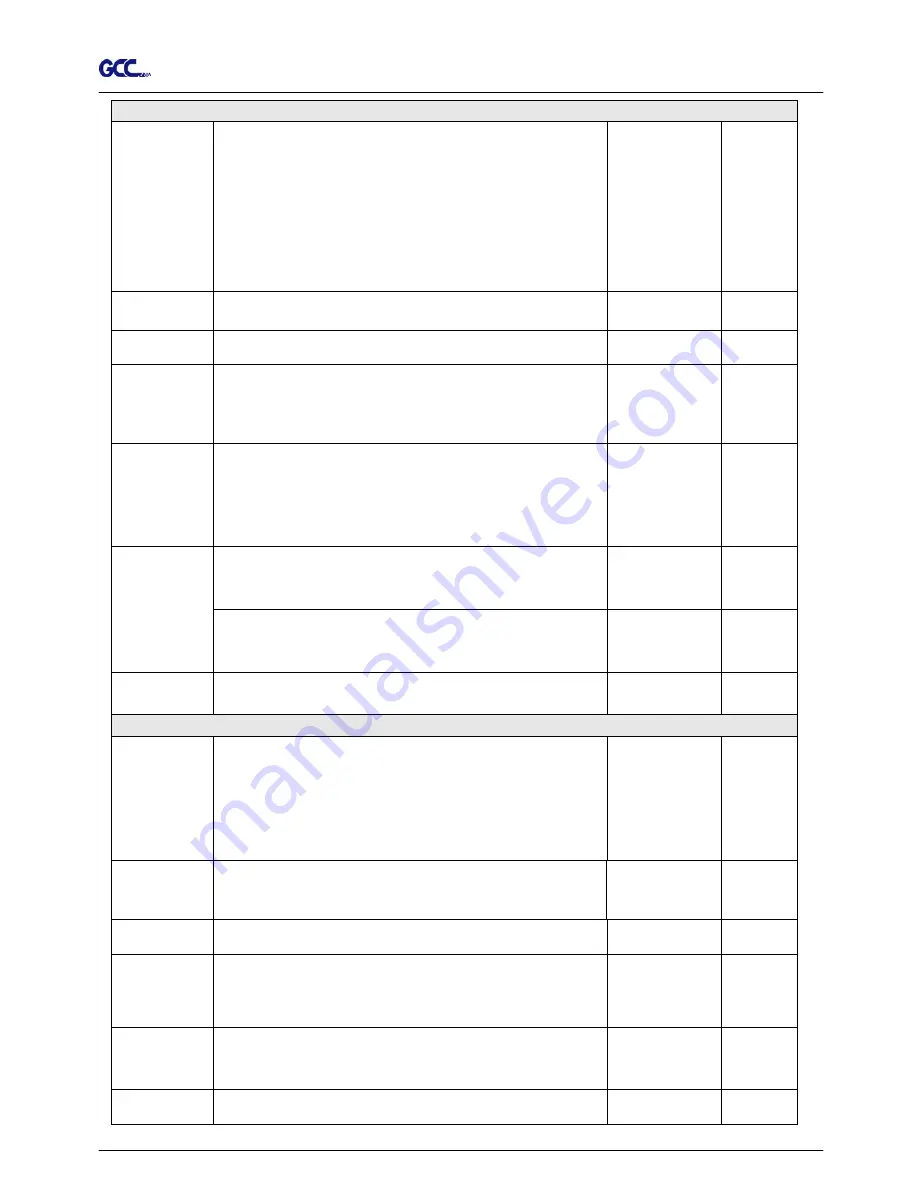

[ TOOL SELECT ]

Save

Parameter

To save pattern(s) of cutting parameters for later use.

There are 4 sets of parameters saved in the panel. Use Page

Up and Page Down keys to select the set of parameters you

wish to adjust, press “Enter” to confirm (the number shown on

the upper left corner will change accordingly). Each set of

parameters includes Speed, Force, Offset, Up Speed and

Quality though the latter two will not be displayed in this

section. To adjust or check individual parameters, go back to

the responding keys on the panel and press “Enter” to

confirm.

Patterns1~4 Pattern

1

Set Smoothing

Cut

To enable smooth-cutting function.

Enable

Over Cut

To generate an overcut to facilitate weeding.

0.00mm-1.00mm

0.05mm/per step

0.00mm

Set Tangential

Mode

To enable the emulated tangential-cutting mode for thicker

media types and small letter cuts.

Note: while the Offset value setting at 0.000 mm, “Set

Tangential Mode” will automatically be disabled.

Enable

Pouncing

To make perforated patterns.

* In order to use this function, Pouncing tool must be installed.

* Before start pouncing, place pouncing strip on top of the

cutting pad to protect the cutting pad.

* Set the value as 0 mm to disable the pouncing mode.

* Pouncing tool is an optional item.

0~200mm 0mm

Accept setup command:

To accept commands of the Force, Speed, Cutting Quality,

and Offset only via software.

Panel Setup

Control panel only:

To accept commands of the Force, Speed, Cutting Quality,

and Offset only via control panel of the cutter.

Restore

Default

To turn all parameters of the menu items to factory-default

settings.

[ MISC ]

Auto Unrolled

Media

To avoid paper jam and motor crash by automatically unroll

media (50cm and up) before cutting while enabled. .

* Auto-unroll only effects on roll/edge media.

* Using Single mode to size media will disable this function

automatically.

* If the length of the rolled media is less than 2 meters or the

weight is light, it is recommended to set this mode disabled.

Enable

Vacuum

To help improve tracking and cutting accuracy by turning on

the fans. If you turn off the vacuum system, the fans

will remain inactive during cutting or plotting.

Enable

AAS Offset

To set or modify AAS offset value.

You can refer to “5.3 Printer Test” for more details.

Media Back

& Forth

To enable to save time on repeated cutting jobs and better

tracking.

After cutting job has finished, the media will move back to the

origin, then move to the end of the plot.

Disable

Paper Saving

Mode

To save media by four different modes:

1. Length expanded mode 2. Width expanded mode

3. Both expanded mode 4. Both unexpanded mode

Both

unexpanded

mode

Set

Communication

To build up the communication between host computer and

cutter.

Summary of Contents for J4-101S

Page 1: ...Jaguar IV Series User Manual http www GCCworld com V 6 2012 Mar ...

Page 22: ...Jaguar IV User Manual Installation 2 11 Figure 2 21 Figure 2 20 ...

Page 90: ...Jaguar IV User Manual SignPal 8 5 Instruction A 4 z 9 ...

Page 93: ...Jaguar IV User Manual SignPal 8 5 Instruction A 4 z 12 4 Select the printer and paper size ...

Page 98: ...Jaguar IV User Manual SignPal 8 5 Instruction A 4 z 17 ...