3

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

2 OPERA

2 OPERA

2 OPERA

2 OPERA

2 OPERATOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMATION

TION

TION

TION

TION

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

7 F

7 F

7 F

7 F

7 FAUL

AUL

AUL

AUL

AULT FINDING

T FINDING

T FINDING

T FINDING

T FINDING

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

Impor

Impor

Impor

Impor

Important Information

tant Information

tant Information

tant Information

tant Information -----------------------------------------

-----------------------------------------

-----------------------------------------

-----------------------------------------

----------------------------------------- 4

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Introduction

oduction

oduction

oduction

oduction

1-1 Introduction ---------------------------------------------- 5

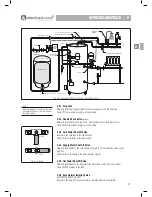

1-2 System Layout ------------------------------------------- 8

1-3 Parts Supplied------------------------------------------- 11

1-4 The Electrastream System ------------------------------- 12

1-5 Tri Core Heater Operation -------------------------------- 13

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Controls

ols

ols

ols

ols

2-1 System Control ------------------------------------------ 14

2-2 Electrastream Control Unit ------------------------------- 16

2-3 Shut Off Valves ------------------------------------------ 20

2-4 Temperature & Pressure Relief Discharge ---------------- 22

2-5 Thermostatic Mixing Valve ------------------------------ 22

2-6 Servicing ------------------------------------------------ 22

Section 3 T

Section 3 T

Section 3 T

Section 3 T

Section 3 Technical Information

echnical Information

echnical Information

echnical Information

echnical Information

3-1 Specifications ------------------------------------------- 23

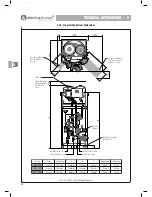

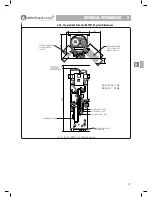

3-2 Dimensions --------------------------------------------- 25

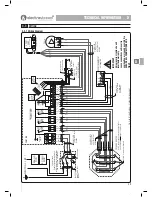

3-3 Wiring --------------------------------------------------- 29

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

4-1 Building Control ----------------------------------------- 31

4-2 Electrical ------------------------------------------------ 31

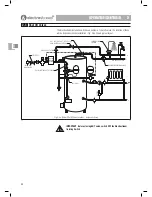

4-3 Hot Water System --------------------------------------- 33

4-4 Heating System ----------------------------------------- 37

4-5 Expansion Discharge ------------------------------------ 40

4-6 System Pressure ---------------------------------------- 43

4-7 Electrastream Connections - ---------------------------- 44

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

5-1 Commissioning ----------------------------------------- 47

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

6-1 Routine Service ----------------------------------------- 50

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

7-1 Fault Finding -------------------------------------------- 52

Health & Safety

Health & Safety

Health & Safety

Health & Safety

Health & Safety ------------------------------

------------------------------

------------------------------

------------------------------

------------------------------ Inside Front Cover

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

4 INST

4 INST

4 INST

4 INST

4 INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

IMPORTANT

BEFORE STARTING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE

BEEN DELIVERED AND ARE IN SATISFACTORY CONDITION - Refer to 1-3 .

HEAL

HEAL

HEAL

HEAL

HEALTH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

15

OPERA

OPERA

OPERA

OPERA

OPERATOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2

TOR CONTROLS 2

If the over temperature cut-out trips more than once, switch off the Electrastream

isolating switch and contact your installer.

2-1.4 Heating Motorised Valve

When the room thermostat is calling for heat and the Electrastream control unit is set for

heat ON, the heating motorised valve will open allowing water to the radiators.

Display icon ‘Valve

’ indicates the valve is open.

2-1.5 Pump

The heating circulating pump is controlled by the Electrastream Control Unit in response

to the room thermostat.

The pump has 3 speeds, it is normally set to speed 2 (II). Consult the Electrastream

installer before changing this setting - see 4-4.3.

Display icon ‘Pump

’ indicates the pump is ON.

2-1.6 Room Thermostat

The room thermostat controls the heat within the property.

When the room thermostat is calling for heat and the Electrastream control unit is set for

heat ON, the heating circulating pump will run, pumping water through the radiators.

Display icon ‘Therm

’ indicates the room thermostat is calling for heat.

2-1.7 Tri-core Heater Elements

The three elements heat the water in the cylinder when the Electrastream control unit is

programmed for a heat cycle. The elements are switched On and Off by the

Electrastream control unit in response to the temperature within the cylinder as detected

by the temperature sensor.

The elements have a staggered On sequence to prevent sudden loads - see 1-5.

Display icons ‘Heat 1

, Heat 2

, and Heat 3

indicate that the elements are

heating.

If either of the Heat icons are displaying an exclamation mark ‘!’

‘!’

‘!’

‘!’

‘!’ this indicates a fault with

an element - see 2-2.3.

2-1.8 Residual Current Device (RCD)

The Electrastream system will be protected by a Residual Current Device, this will

automatically switch Off the electric supply if an earth fault develops.

The RCD must be tested at least every three months, this is done by pressing the RCD

‘Test’ or ‘T’ button, this should switch the supply Off. Reset RCD to On after test.

If the RCD appears not to be working correctly contact your installer or a qualified

electrician.

2-1.9 Alternative Heat Source Controls

For twin coil systems the alternative heat source will have its own controls - refer to

manufacturers instructions.

The alternative heat source would normally be a cost effective method of heating the

cylinder and should be used and controlled for optimum performance thus reducing

heating costs.

Note

Testing the RCD will not cause loss of the

Electrastream Control Unit settings.

Note

Refer to 2-2 for the Electrastream Control

Unit display and settings.

IMPORTANT

When a programmable room

thermostat is used it should only be

set to call for heat when ‘Economy

Tariff’ is available.

22222

Summary of Contents for Electrastream

Page 55: ...55 ...