2

Important Health and Safety Information for Installers and Service Engineers

Health and Safety at Work Act 1974

Consumer Protection Act 1987

COSHH Regulations 1988

The following information is given as a requirement of the

above legislation.

Great care is taken by GAH (HEATING PRODUCTS) LIMITED

to ensure that Electrastream systems are designed and

manufactured to meet general safety requirements when

properly used and installed as recommended in this manual.

It is the responsibility of Users and Engineers to ensure that

adequate protective clothing and glasses are worn when

working with the Electrastream system.

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

Insulation and sealing materials are used in the construction

of the Electrastream cylinders. Units are sealed and when

used in the manner for which they are intended the insulating

and sealing materials do not present any known hazard.

However always observe the following recommendations:-

1. Avoid inhalation of fibres or dust, wear face mask.

2. Avoid eye contamination by fibres or dust - wear eye

protection.

3. As far as possible avoid any skin contact with Fibreglass

Insulation, Glass Rope, Mineral Wool, Insulation Pads and

Ceramic Fibre.

PPPPPatent application 01514800.2

atent application 01514800.2

atent application 01514800.2

atent application 01514800.2

atent application 01514800.2

©

©

©

©

©

2010 GAH (HEATING PRODUCTS) L

2010 GAH (HEATING PRODUCTS) L

2010 GAH (HEATING PRODUCTS) L

2010 GAH (HEATING PRODUCTS) L

2010 GAH (HEATING PRODUCTS) LTD.

TD.

TD.

TD.

TD.

Electrastr

Electrastr

Electrastr

Electrastr

Electrastream is a T

eam is a T

eam is a T

eam is a T

eam is a Trademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) LTD.

TD.

TD.

TD.

TD.

Manual by Harber Technical Services Tel/Fax 01263 515444

E-mail:[email protected] www.harbertech.co.uk

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Products) Ltd.

oducts) Ltd.

oducts) Ltd.

oducts) Ltd.

oducts) Ltd.

Building 846

Bentwaters Parks

Rendlesham

Woodbridge

Suffolk IP12 2TW

TTTTTel:

el:

el:

el:

el: 01394 421160

01394 421160

01394 421160

01394 421160

01394 421160

Fax:

Fax:

Fax:

Fax:

Fax: 01394 421170

01394 421170

01394 421170

01394 421170

01394 421170

email: [email protected]

www.gah.co.uk

In pursuance of a policy of constant development, GAH (HEATING PRODUCTS) LIMITED

reserve the right to change Electrastream parts or design without notice, therefore

certain details included in this manual may not be correct at the time of printing. Any

modification and improvements detailed in this manual does not commit GAH to update

any system previously supplied.

Manual Part No. ...................MAN1019

Manual Ref ..........................ES02

Issue ...................................13

Date ....................................25/02/13

GAH (HEATING PRODUCTS) LIMITED will not accept

responsibility for any damage or personal injury caused

by not giving due consideration to the above safety

recommendations.

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

SEALANTS, ADHESIVES AND PAINTS

Sealants, Adhesives and Paints are used in the construction of

the Electrastream components. When used in the manner for

which they are intended they do not present any known hazard.

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

The Cylinder Tri-Core Heater, Pump, Thermostats and Contactor

Box all have electrical supply of 230V (enough to endanger

life).

Always isolate before connection, adjustment, servicing and

repair.

When the Tri-Core Heater cover is removed high power live

electrical terminals are exposed.

ISOLATE THE TRI-CORE HEATER BEFORE REMOVING ITS

COVER.

Earth protection - Earth Continuity Conductors must be fitted

and must comply with IEE Wiring Regulations.

HTS REF GAH ELECTRASTREAM 25/02/13

HEAL

HEAL

HEAL

HEAL

HEALTH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

12

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

Note

All installations must comply with relevant

regulations - refer to section 4-1.

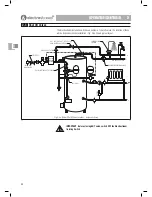

1-4.1 Hot & Cold Water Supply

Refer to fig. 1-2a for Electrastream.

Refer to fig. 1-2b for Electrastream Twin Coil

The incoming mains water supply is connected to the combination valve which is

assembled to the unvented indirect hot water cylinder. The combination valve has an

integral check valve. A single check valve is supplied, this is only required to be fitted if

back syphonage is possible from any item fitted prior to the combination valve.

Provision should also be provided in the cold supply for:-

1. Heating system fill.

2. Drinking water.

3. Water softener (when applicable).

4. Outside tap (when applicable).

The combination valve limits the incoming pressure to 3.5 Bar, it has an integral non-

return valve and pressure relief valve (PRV).

Supply to the hot outlets is taken from the cylinder and mixed with cold water by the

thermostatic mixing valve, this ensures that a safer lower temperature hot water is

available at outlets.

Cold supply to all outlets is taken direct from the main supply. If the mains pressure is

high (over 3.5 Bar) a 3.5 Bar pressure reducing valve is recommended.

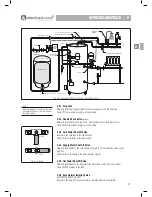

1-4.2 Twin Coil - Alternative Heat Source

Twin Coil Cylinders have two coils, the upper coil is connected to the Electrastream

heating system. The Electrastream high powered titanium electric tri-core heater is

positioned about halfway up the cylinder so that it is only used to heat the water in the

upper part of the cylinder.

The lower coil is heated by the chosen alternative heat source (e.g. solar), this will heat

the water in the whole cylinder when ‘energy’ is available resulting in optimum efficiency.

1-4.3 System Control

The Electrastream system is controlled by a purpose designed Electrastream Control

Unit, this controls the hot water and heating ON/OFF times together with the heating

pump and valve. The control also has a dedicated programme that ensures efficient use

of electricity by selecting how many of the three immersion heater elements are required

to meet the current demand for heating or hot water.

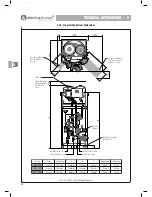

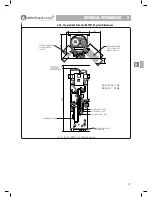

1-4.4 Heating System

The heating system is for water filled radiators on a standard ‘sealed system’. The water

for the heating is heated by being pumped through the indirect coil of the cylinder. A

room thermostat and the Electrastream Control Unit’s programmable timers control the

circulating pump and motorised valve.

1-4.5 Electric System

The unvented cylinder is heated by a 240V, 9kW (combined 3 x 3kW) titanium tri-core

heater. This is controlled by the cylinder temperature sensor and the Electrastream

Control Unit.

Electrastream is designed to make full use of economy tariff electricity supplies and the

wiring must be arranged to make full use of this.

Note

The final fill of the heating system should

include the correct percentage of suitable

scale/corrosion inhibitor.

1-4

The Electrastream System

Note

The alternative heat source must be

configured correctly to be used with the

GAH Electrastream system.

11111

Summary of Contents for Electrastream

Page 55: ...55 ...