3

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

1 INTRODUCTION

2 OPERA

2 OPERA

2 OPERA

2 OPERA

2 OPERATOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

TOR CONTROLS

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMA

3 TECHNICAL INFORMATION

TION

TION

TION

TION

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

5 COMMISSIONING

7 F

7 F

7 F

7 F

7 FAUL

AUL

AUL

AUL

AULT FINDING

T FINDING

T FINDING

T FINDING

T FINDING

CONTENTS

CONTENTS

CONTENTS

CONTENTS

CONTENTS

Impor

Impor

Impor

Impor

Important Information

tant Information

tant Information

tant Information

tant Information -----------------------------------------

-----------------------------------------

-----------------------------------------

-----------------------------------------

----------------------------------------- 4

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Intr

Section 1 Introduction

oduction

oduction

oduction

oduction

1-1 Introduction ---------------------------------------------- 5

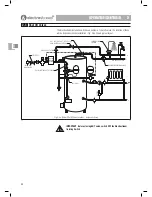

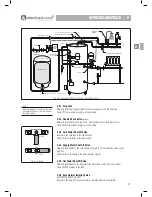

1-2 System Layout ------------------------------------------- 8

1-3 Parts Supplied------------------------------------------- 11

1-4 The Electrastream System ------------------------------- 12

1-5 Tri Core Heater Operation -------------------------------- 13

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Contr

Section 2 Operator Controls

ols

ols

ols

ols

2-1 System Control ------------------------------------------ 14

2-2 Electrastream Control Unit ------------------------------- 16

2-3 Shut Off Valves ------------------------------------------ 20

2-4 Temperature & Pressure Relief Discharge ---------------- 22

2-5 Thermostatic Mixing Valve ------------------------------ 22

2-6 Servicing ------------------------------------------------ 22

Section 3 T

Section 3 T

Section 3 T

Section 3 T

Section 3 Technical Information

echnical Information

echnical Information

echnical Information

echnical Information

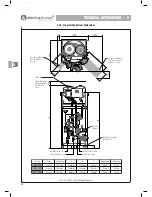

3-1 Specifications ------------------------------------------- 23

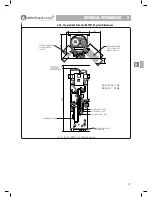

3-2 Dimensions --------------------------------------------- 25

3-3 Wiring --------------------------------------------------- 29

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

Section 4 Installation

4-1 Building Control ----------------------------------------- 31

4-2 Electrical ------------------------------------------------ 31

4-3 Hot Water System --------------------------------------- 33

4-4 Heating System ----------------------------------------- 37

4-5 Expansion Discharge ------------------------------------ 40

4-6 System Pressure ---------------------------------------- 43

4-7 Electrastream Connections - ---------------------------- 44

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

Section 5 Commissioning

5-1 Commissioning ----------------------------------------- 47

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

Section 6 Servicing

6-1 Routine Service ----------------------------------------- 50

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

Section 7 Fault Finding

7-1 Fault Finding -------------------------------------------- 52

Health & Safety

Health & Safety

Health & Safety

Health & Safety

Health & Safety ------------------------------

------------------------------

------------------------------

------------------------------

------------------------------ Inside Front Cover

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

6 SERVICING

4 INST

4 INST

4 INST

4 INST

4 INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

IMPORTANT

BEFORE STARTING THE INSTALLATION OF THE ELECTRASTREAM CHECK ALL COMPONENTS HAVE

BEEN DELIVERED AND ARE IN SATISFACTORY CONDITION - Refer to 1-3 .

HEAL

HEAL

HEAL

HEAL

HEALTH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

TH & SAFETY

13

1-4.6 Output

The tri-core heater provides 9kW (30,000 Btu) for heating and hot water.

1-4.7 Scale Protection

IMPORTANT All installations should have a scale protection device fitted

and in areas known to have hard water, a water softening device is

strongly recommended. The cylinder is not guaranteed against damage

caused by scale. Higher water temperatures of 65°C and above can

cause excessive scale.

GAH recommend and promote the use of scale prevention devices and water softeners in

areas that are known to have hard water. Installed correctly they prolong the life of

equipment and help prevent limescale formation in the pipework. Water softeners

provide the advantages of soft water, as well as preventing scale build up on taps and

shower heads.

Water softeners and any mains fed system must be of adequate capacity and should be

installed with suitably sized hoses to prevent any possibility of flow reduction.

1-4.8 Frost Protection

When planning the installation location of both the accumulator and the unvented

cylinder, consideration must be given to the risk of frost and the use of frost protection.

The design of the accumulator gives it a degree of frost protection enabling it to be

located within the dwelling, loft space or garage without further protection.

The cylinder can also be installed within the dwelling or loft space without further

protection.

Cylinders or accumulators must have frost protection when they are installed where low

temperatures could be a potential problem. Cylinders can be protected by a frost

thermostat.

To comply with Building Regulations, all necessary pipework must be suitably lagged.

1-4.9 Handling and Storage

The Electrastream system will be delivered fully wrapped and palleted.

Lift the package carefully using a safe and suitable lifting method.

Keep the packaging intact and store in a secure dry and weatherproof area prior to

installation.

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

INTRODUCTION 1

1-5

Tri-core Heater Operation

The three elements of the tri-core heater are switched on and off by the Electrasteam

Control Unit. They have a staggered switch on sequence that prevents sudden high load

on the power supply.

The control unit also limits the use of the elements for efficiency.

When the hot water within the cylinder is within 2° of the set (8) Target 65°C, only one

element will be on.

When the hot water within the cylinder is between 2° and 4°C below the set (8) Target

65°C, then two elements will be on.

When the hot water within the cylinder is below 6°C of the set (8) Target 65°C, then all

three elements will be on.

Note

When a water softener is fitted, the take-

offs for heating system fill, drinking water

and outside tap (when applicable), must

be positioned before the water softener.

Note

Refer to 2-2.2 for display settings.

GAH offer a range of quality Water

Softeners, for information contact

GAH (HEATING PRODUCTS) LTD.

IMPORTANT

On twin coil cylinders the

Electrastream tri-core heater must

be fitted to the upper immersion

heater tapping.

11111

Summary of Contents for Electrastream

Page 55: ...55 ...