Summary of Contents for CSH-83

Page 1: ...COLOR SCANNING SONAR MODEL CSH 83 84 Back ...

Page 6: ...This page is intentionally left blank ...

Page 11: ...3 2 Heater Heat insulator Figure 3 2 Typical sonar compartment ...

Page 68: ...A 10 ...

Page 77: ...A 19 ...

Page 78: ...A 20 ...

Page 79: ...A 21 ...

Page 80: ...A 22 ...

Page 81: ...A 23 ...

Page 82: ...A 24 ...

Page 83: ...A 25 ...

Page 84: ...A 26 ...

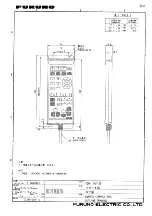

Page 85: ...D 1 ...

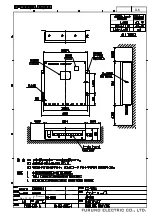

Page 86: ...D 2 ...

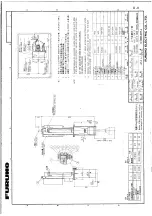

Page 87: ...Y Hatai D 3 ...

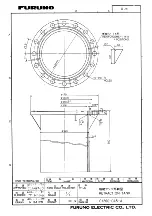

Page 88: ...D 4 ...

Page 89: ...Oct 31 03 D 5 ...

Page 90: ...Dec 10 02 D 6 ...

Page 91: ...D 7 ...

Page 92: ...D 8 ...

Page 93: ...D 9 ...

Page 94: ...D 10 ...

Page 95: ...D 11 ...

Page 96: ...D 12 ...

Page 97: ...D 13 ...

Page 98: ...D 14 ...

Page 99: ...D 15 ...

Page 100: ...D 16 ...

Page 101: ...D 17 ...

Page 102: ...D 18 ...

Page 103: ...D 19 ...

Page 104: ...D 20 ...