C156-E097-01EN

3 - 3

3.1.2

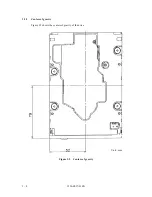

Temperature requirements and measuring method

Table 3.1 shows the temperature requirement at each measurement point shown in Figure 3.1.

Table 3.1

Temperature requirements at measurement points

Measurement point

Maximum surface temperature

Cartridge inside

55°C (*)

IC (controller) surface

75 °C

IC (read amp.) surface

85 °C

Note: * 60°C for the optical disk cartridge manufactured by Fujitsu.

Following procedure is for temperature measurement of inside cartridge.

1) Make a hole for the thermo couple as shown in Figure 3.1.

2) Disassemble the cartridge disk.

3) Cut off a part of the partition wall for the optical media as shown in Figure 3.1. (Cut off

width: 5 to 10 mm)

4) Fix the tip of the thermo couple to the cut portion of partition wall with an adhesive agent.

5) Pass the thermo couple through the hole at the cartridge case and assemble the cartridge disk.

When there is a gap between the hole and the thermo couple, fill the gap with the adhesive

agent.

Note:

1.

If the external environment temperature is higher than the specified value, the device

will automatically take an interval to respond to command, and then take protective

action to respond to the temperature increase.

2.

If the ambient temperature becomes higher than the measured temperature, the device

automatically operates to protect itself from rising temperatures.

3.1.3

Air flow

It is recommended that this optical disk drive be installed in a fanless cabinet. However, if the

power supply is incorporated into the same cabinet, it is recommended that it satisfy the

“Temperature Conditions” in 3.1.2 and that the air flow rate being drawn in by the device) at the

cartridge loading slot be 0.02 m

3

/min, 0.3 m/s or lower. Furthermore, if there is a system fan in a

system where this drive is being installed, the same conditions must be met.

Summary of Contents for MCE3064SS

Page 1: ...C156 E097 01EN MCE3064SS MCF3064SS OPTICAL DISK DRIVES PRODUCT MANUAL ...

Page 3: ...This page is intentionally left blank ...

Page 31: ...This page is intentionally left blank ...

Page 52: ...C156 E097 01EN 2 21 Figure 2 3 Example of alternate processing ...

Page 53: ...This page is intentionally left blank ...

Page 72: ...C156 E097 01EN 3 19 Figure 3 17 SCSI cable connector ...

Page 81: ...This page is intentionally left blank ...

Page 97: ...4 16 C156 E097 01EN Figure 4 5 SCSI connection check 2 ...

Page 99: ...This page is intentionally left blank ...

Page 113: ...This page is intentinally left blank ...

Page 119: ...7 2 C156 E097 01EN Host system A Host system B Figure 7 1 Example of SCSI configuration ...

Page 133: ...7 16 C156 E097 01EN Figure 7 6 ARBITRATION phase ...

Page 135: ...7 18 C156 E097 01EN µ Figure 7 7 SELECTION phase 30 30 30 30 ...

Page 141: ...7 24 C156 E097 01EN Figure 7 10 Transfer in asynchronous mode 18 18 ...

Page 145: ...7 28 C156 E097 01EN Figure 7 11 Transfer in synchronous mode 11 11 11 11 43 18 43 18 ...

Page 146: ...C156 E097 01EN 7 29 Figure 7 12 Transfer in FAST SCSI mode ...

Page 148: ...C156 E097 01EN 7 31 Figure 7 13 Data transfer rate in asynchronous mode ...

Page 158: ...C156 E097 01EN 7 41 Figure 7 17 RESET condition ...

Page 160: ...C156 E097 01EN 7 43 Figure 7 18 Bus phase sequence 1 of 2 ...

Page 161: ...7 44 C156 E097 01EN Figure 7 18 Bus phase sequence 2 of 2 ...

Page 167: ...This page is intentionally left blank ...

Page 171: ...This page is intentionally left blank ...

Page 181: ......