LM2A Wall Mounted Solution

Page

5

of

20

Fuji Electric Europe GmbH

Installation

Wiring

•

If there

isn’t zero-phase current (Earth leakage current) detective device, such as a ground-fault relay in

the upstream power supply line, which is to avoid undesirable system shutdown. Install a residual-

current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) individually to break the

individual inverter’s power supply line.

Otherwise, a fire could occur.

•

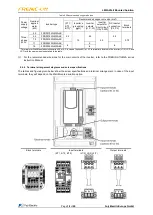

When wiring the inverter to the power source, insert a recommended molded case circuit breaker (MCCB)

or residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) (with

overcurrent protection) in the path of each pair of power lines to inverters. Use the recommended devices

within the recommended current capacity.

•

Use wires in the specified size.

•

Tighten terminals with specified torque.

Otherwise, a fire could occur.

•

When there is more than one combination of an inverter and motor, do not use a multicore cable for the

purpose of running their wirings together.

•

Do not connect a surge killer to the inverter's output (secondary) circuit.

Doing so could cause a fire.

•

Be sure to ground the inverter's grounding terminals G.

Otherwise, an electric shock or a fire could occur.

•

Qualified electricians should carry out wiring.

•

Be sure to perform wiring after turning the power OFF.

Otherwise, an electric shock could occur.

•

Be sure to perform wiring after installing the cabinet unit.

Otherwise, an electric shock or injuries could occur.

•

Ensure that the number of input phases and the rated voltage of the product match the number of phases

and the voltage of the AC power supply to which the product is to be connected.

Otherwise, a fire or an accident could occur.

•

Do not connect the power supply wires to the inverter output terminals (U, V, and W or U0, V0, and W0).

Doing so could cause fire or an accident.

•

Do not place flammable object nearby.

Doing so could cause fire.

•

Do not support the cabinet by its front cover during transportation.

Doing so could cause a drop of the inverter and injuries.

•

Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

cabinet, specially into the inverter or from accumulating on the heat sink.

•

When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or an accident might result.

•

Do not install or operate an inverter that is damaged or lacking parts.

Doing so could cause fire, an accident or injuries.