LM2A Wall Mounted Solution

Page

17

of

20

Fuji Electric Europe GmbH

4. Maintenance and Inspection

Perform daily and periodic inspections to avoid trouble and keep reliable operation of the inverter and components

for a long time.

4.1 Daily Inspection

Visually inspect the inverter and other components for operation errors from the outside without removing the covers

when the inverter is ON or operating.

-

Check that the expected performance (satisfying the standard specifications) is obtained.

-

Check that the surrounding environment satisfies the environmental requirements given in Chapter 2, Section

2.1.

-

Check that the keypad displays normally.

-

Check for abnormal noise, odor, or excessive vibration.

-

Check for traces of overheat, discoloration and other defects.

4.2 Periodic Inspection

Before starting periodic inspections, be sure to stop the motor, shut down the power, and wait at least 10 minutes.

Make sure that the charging lamp on the inverter is turned OFF. Further, make sure, using a multimeter or a similar

instrument, that the DC link bus voltage between the main circuit terminals P(+) and N(-) has dropped to the safe

level (+25 VDC or below).

For the complete list of inverter periodic inspection, refer to the FRENIC-Lift LM2A series Instruction Manual.

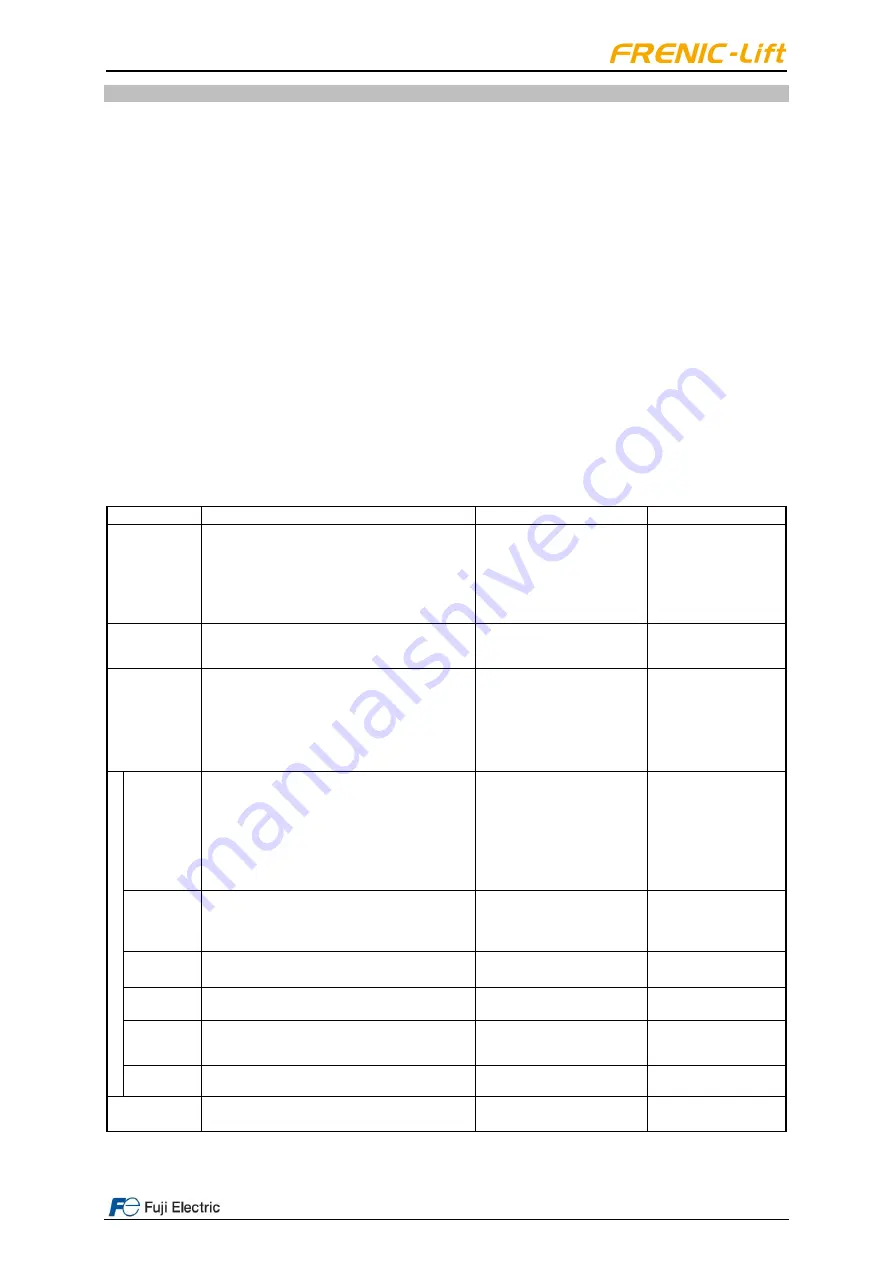

Table 4.1 List of Periodic Inspections

Check part

Check item

How to inspect

Evaluation criteria

Environment

1) Check the ambient temperature, humidity,

vibration and atmosphere (dust, gas, oil mist, or

water drops).

2) Check that tools or other foreign materials or

dangerous objects are not left around the

equipment.

1) Check

visually

or

measure using apparatus.

2) Visual inspection

1) The

standard

specifications must be

satisfied.

2) No

foreign

or

dangerous

objects

are left.

Input voltage

Check that the input voltages of the main and

control circuit are correct.

Measure the input voltages

using a multimeter or the like.

The

standard

specifications must be

satisfied.

Structure such

as frame and

cover

Check for:

1) Abnormal noise or excessive vibration

2) Loose bolts (at clamp sections).

3) Deformation and breakage

4) Discoloration caused by overheat

5) Contamination and accumulation of dust or

dirt

1) Visual or auditory

inspection

2) Retighten.

3), 4), 5)

Visual inspection

1), 2), 3), 4), 5)

No abnormalities

Ma

in

c

ir

c

u

it

Common

1) Check that bolts and screws are tight and

not missing.

2) Check the devices and insulators for

deformation,

cracks,

breakage

and

discoloration

caused

by

overheat

or

deterioration.

3) Check for contamination or accumulation of

dust or dirt.

1) Retighten.

2), 3)

Visual inspection

1), 2), 3)

No abnormalities

Conductors

and wires

1) Check conductors for discoloration and

distortion caused by overheat.

2) Check the sheath of the wires for cracks and

discoloration.

1), 2)

Visual inspection

1), 2) No abnormalities

Terminal

blocks

Check that the terminal blocks are not

damaged.

Visual inspection

No abnormalities

Reactor

Check for abnormal roaring noise and odor.

Auditory,

visual,

and

olfactory inspection

No abnormalities

Magnetic

contactors

1) Check for chatters during operation or

vibrations.

2) Check that contact surface is not rough.

1) Auditory inspection

2) Visual inspection

1), 2) No abnormalities

Main switch 1) Check that it is not damaged.

2) Check that it can change the position.

1),

2) Visual or auditory

inspection

1), 2) No abnormalities

Cooling

system

Check the heat sink, intake and exhaust ports

for clogging and foreign materials.

Visual inspection

No abnormalities

Remove dust accumulating on the inverter and other components with a vacuum cleaner. If a component is stained,

wipe it off with a chemically neutral cloth.