VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-210 IOM (

JUL

09)

Page 19

should be taken to ensure that the Vyper

™

and the associated

piping and wiring do not obstruct access to service areas.

VYPER

™

COOLING CONFIGURATION

The Frick Vyper

™

is internally cooled with a factory cali-

brated liquid cooling circuit that offers many advantages

over traditional air-cooled systems. The liquid circuit pro-

vides precisely controlled coolant temperatures to the heat

generating components and delivers coolant into locations

that air-over fan systems could not penetrate. The Vyper

™

liquid-cooling arrangement performs independently of fluctu-

ating ambient conditions. The NEMA 4 indoor-rated cabinet

seals the internal electronics and piping from corrosive

refrigerant vapors while providing superior cooling for the

internal electronic components. Efficient liquid cooling also

allows for smaller cabinet size and longer component life

than traditional air-cooled units. Plant condenser water or a

facility-supplied glycol loop subsequently removes the heat

in the coolant via the heat exchanger located at the back of

the Vyper

™

cabinet.

VYPER

™

COOLING LOOP

While the compressor is running, the Quantum

™

LX control

panel monitors the temperature of Vyper

™

drive coolant. With

this information, the Quantum

™

LX delivers a 4-20 mA signal

to the 3-way mixing valve, based on the setpoints of a PID

loop output from the Quantum

™

LX. This signal will maintain

the Vyper

™

coolant temperature at the control setpoint for

the PID loop. This setpoint will be set at 110°F at the factory.

There are also low and high temp alarms and shutdowns as-

sociated with the Vyper

™

coolant temperature reading. These

wil also be factory set for a Low Temp. alarm and shutdown

at 85°F and 80°F with a 90 second delay, when running. The

High Temp. Alarm and shutdown will be factory set at 125°F

and 130°F with a 30 second delay when running. If the Vyper

™

coolant temperature drops too low, condensation may occur,

damaging vital electronic components.

In addition to controlling the Vyper

™

cabinet cooling system,

the Quantum

™

LX panel also monitors the temperature of four

components in the Vyper

™

cabinet. If any of these tempera-

tures reaches a critical threshold, the Quantum

™

LX panel will

enter a Stop Load condition, preventing either the slide valve

position or motor speed from increasing. If the temperature

continues to rise, the Quantum

™

LX panel will next go to a

Force Unload condition. In this situation, the slide valve will

unload to lower the motor torque required, in an effort to drop

the temperature in the panel. Table 7 shows the Stop Load

and Force Unload temperatures as well as the temperatures

where the Vyper

™

cabinet will automatically shut down.

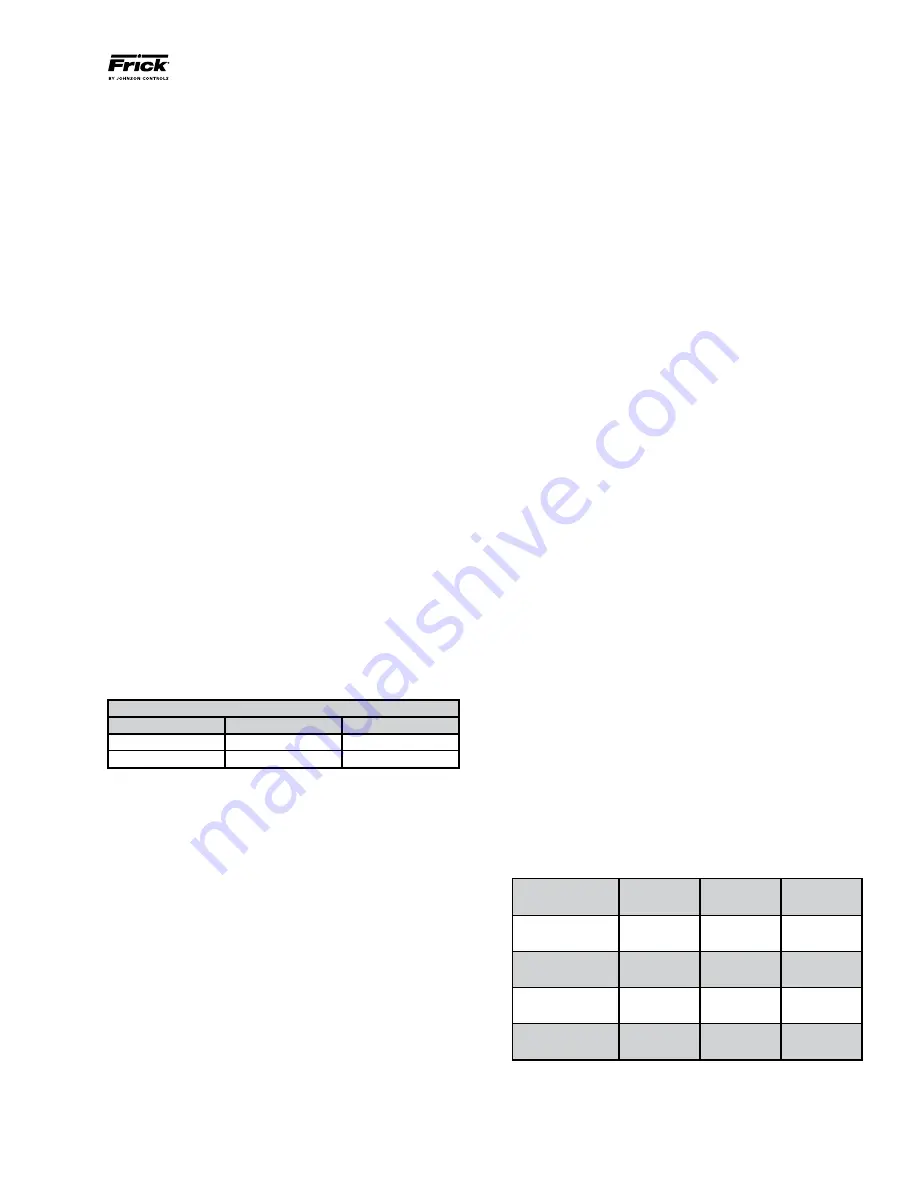

Location

Stop Load

Force

Unload

Shutdown

Baseplate Temp

Inverter

160°F

(71°C)

165°F

(74°C)

170°F

(77°C)

Heat Sink Temp

155°F

(68°C)

160°F

(71°C)

158°F

(70°C)

Harmonic Filter

130°F

(54°C)

135°F

(57°C)

145°F

(63°C)

Baseplate Temp

160°F

(71°C)

165°F

(74°C)

175°F

(79°C)

Table 7 – Vyper

™

Cabinet Component Temperature Thresholds

REMOTE MOUNTED UNITS

For the remote mounting method, the Vyper

™

cabinet is

mounted on a steel stand specifically designed for the VSD.

The primary requirement for mounting the Vyper

™

is that the

foundation must be able to support the weight of the cabinet

and stand. In addition, the remote stand and Vyper

™

cabi-

net must be located so that no more than fifty (50) feet (15

meters) of motor wiring length is needed between the VSD

cabinet and the package motor.

The remote-mounted units have fastener holes located on

the bottom feet for floor anchors and on the rear stand legs

for wall anchoring of the stand.

Anchor bolts are recommended to firmly mount the unit to

the foundation. Anchoring the cabinet to a firm foundation

by proper leveling and employment of fastening bolts is the

best assurance for trouble-free installation.

Foundations must be in compliance with local building codes

and materials must be of industrial quality. All electrical

conduits must be metallic, no PVC or other materials are

permitted. The remote-mounted Vyper

™

configuration is

shown in Figure 7. Table 6 provides the dimensions of the

unit and stand. The mounting location of remote-mount units

must be able to support the weight of the Vyper

™

. Dimen-

sions of the package-mount cabinets are identical except for

the elimination of the stand. Coolant connections to the heat

exchanger are 1½ in. NPT.

ENVIRONMENT

The Vyper

™

is housed in a NEMA 4 indoor class enclosure.

The electronics are sealed against ambient conditions, how-

ever it is recommended that the end user employ good stan-

dard practices in regard to moisture exposure and extreme

temperature conditions. It is recommended that the Vyper

™

be operated within the ambient temperature range of 41°F

(5°C) and 135°F (57°C) with the dew point no higher than

90°F (32°C). Refer to Table 6 for temperature limits.

Recommended Ambient Temperature Limits

Unit Status

Min

Max

Storage

-4°F (-20°C)

158°F (70°C)

Operating

41°F (5°C)

135°F (57°C)

Table 6 – Ambient Temperature Operating Limits.

The Vyper

™

can be used at altitudes up to 10,000 feet (3048

meters) without derating for units without the IEEE 519

Harmonic Filter. A Vyper

™

with the Harmonic Filter option

included can be operated up to 5,000 feet (1524 meters)

without derating. Remotely mounted units must have the

distance limited between the Vyper

™

and the compressor

motor to fifty (50) feet (15 meters) of wire or less. Problems

that may be encountered with wire lengths greater than fifty

feet are as follows:

• VSD picks up interference in the control wiring, causing

the VSD to intermittently trip.

• Voltage drop becomes excessive, rising above the 5%

voltage drop limit.

•

Peak voltage applied to the motor windings becomes

excessive and may cause premature motor failure.

• A

dV/dt filter must be installed on remote-mounted units

with motor power lead lengths between 3 to 50 feet (1 to

15 meters).

Adequate service clearances, including door swing, must

be maintained around the Vyper

™

. During installation, care