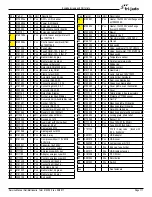

Page 108

Trouble Shooting

Service Manual Deli Multisserie form 9123560 rev. 02/2017

Description of part

Symptoms

Possible cause

Action

Sensor

Temperature read-out on

LCD is not stable.

Upper sensor defect.

Wire loose.

Check sensor and wiring.

See also input test in service

menu

Product over cooked.

Cooking takes more time.

Uneven cooking.

Upper or lower sensor de-

fect. (resistance too low)

Check sensor and wiring.

See also input test in service

menu

Cooking takes more time

Upper or lower sensor de-

fect. (resistance too high).

Check sensor and wiring.

See also input test in service

menu

Uneven cooking (difference

between lower and higher

racks)

Upper or lower sensor

defect.

Offset parameter not

right adjusted. See service

menu.

Check sensor and wiring.

See also input test and para-

meters in service menu.

Sliding contact (on

rotor)

Baking program ends too

soon

Bad or no contact (resi-

stance too high).

Clean contact or replace.

Illumination

Less display effect

One or more lamps defect

Calcifying or greasing of

lamp glasses

Broken lamp gasket

Replace lamps.

Clean or replace lamp glas-

ses.

Replace gasket

Air exhaust valve (Vent)

Steam blows along the

doorgaskets.

Trumpet sound when clo-

sing the door

Whisle sound at the exhaust

Product too wet

Product too dry

Air exhaust valve clogged

Air Exhaust valve mal-

function

Check and or clean exhaust

pipe and valve

Check valve motor

Check position switches on

valve motor

Watervalve

Product too dry.

Product too wet.

Product not well proofed.

(Bake version).

Cleaning not ok.

Watervalve coil defect.

Filter clogged.

Dirt in watervalve.

Reducer in watervalve

clogged.

Reducer in watervalve not

well mounted.

Check coil.

Clean valve if possible.

Replace valve AND reducer.

Water supply

Product too dry.

Product not well proofed.

(Bake version).

Cleaning not ok.

Water tap closed.

Water pressure too low

(<2bar).

Filters blocked.

Kink in hose.

Open tap.

Check pressure.

Check filters

Search for a kink in the hose.

Tubes calcified

Product too dry.

Product not well proofed.

(Bake version)

Supply water not decal-

cified.

Decalcifying equipment

not ok.

Decalcifying filter satura-

ted.

Check water hardness.

Change filter.

Door switch

Message door open appears

while door is closed

Reed contact door shor-

ted.

Wiring shorted.

Check reed contact and/or

wiring. Replace if necessary

Blowers,heaters and ro-

tor stay on while door is

opened.

Reed contact defect.

Wiring loose.

Check reed contact and/or

wiring. Replace if necessary