possible, the pump and piping system must be drained

completely of water to prevent possible damage.

Decide how to seal the well from surface contamination

as required by local authorities. The most common device

for this purpose is the Sanitary Well Seal. If the pipes

from the well have to be kept below the frost line, either

bury the wellhead or use a Pitless Adapter that leaves the

wellhead exposed for servicing while providing sealed

openings in the well casing below the frost line.

GENERAL PIPING

Follow all state and local plumbing codes.

Plan your piping layout before starting the installation so

that the correct pipe and fittings are on hand to complete

the job.

Keep the pipes clean, since pebbles and other foreign

material can block the injector or pump impeller.

Make sure that the bottom of your suction pipe is at least

3’ below the lowest dynamic water level in the well, and

not closer than 3’ from the bottom of the well.

If you use poly pipe with barbed adapters we recommend

two hose clamps at every fitting connection to protect

against leaks.

HORIZONTAL OFFSET PIPING (Horizontal piping

between the top of the well and the pump)

A jet pump performs best when installed close to the well

because suction lift and friction losses are kept to a

minimum. Although an installation near the water source

is preferred, it may be necessary or more convenient to

locate the pump away from the well. High spots in the

piping between the top of the well and the pump will

create air pockets and make priming the system very

difficult. To avoid air pockets slope horizontal pipes

continuously upward from water source to pump by at

least 1 vertical inch for every 30” of Horizontal run. When

the pump is offset from the well, the horizontal offset

suction piping may have to be increased in diameter to

reduce pressure loss. The pressure loss in a system

increases:

1.) As the flow rate increases

2.) As the piping size decreases

Consult included friction loss tables (Appendix III) to

determine the amount of head loss for a given

application.

DISCHARGE PIPING

When the pump is located a long distance from points of

water use, it may be necessary to increase the discharge

pipe size in order to reduce pressure loss. The pressure

loss in a system increases:

1.) As the flow rate increases

2.) As the piping size decreases

Consult included friction loss tables (Appendix III) to

determine the amount of head loss for a given application.

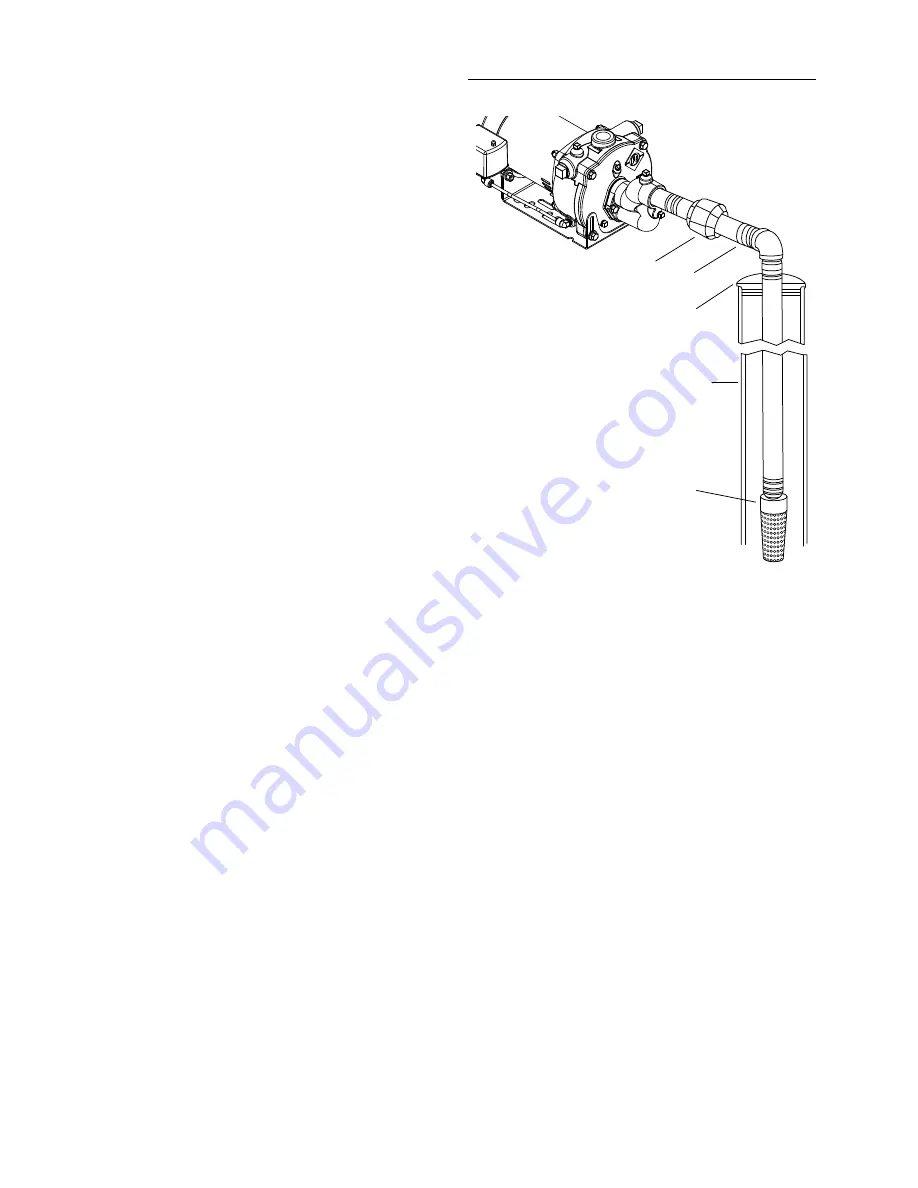

SHALLOW WELL INSTALLATION (FIGURE 1 & 2)

SHALLOW WELL SUCTION PIPING (FIGURE 1)

Suction tapping on the pump is 1-1/4” (FNPT) in size.

Suction pipe diameter should never be smaller than the

suction tapping. Use of smaller pipe reduces flow and

pressure in the system. We recommend increasing the

suction line size as the length of horizontal offset piping

increases (see “HORIZONTAL OFFSET PIPING” above).

Shallow well operation, suitable for depths not exceeding

25 feet, requires only a single pipe to the water source.

Typical water sources are wells, lakes, ponds, streams,

or rivers. Support the suction pipe, so its weight is not

carried by the pump. Installation should include a foot

valve in the well (preferred) or a check valve as close to

the water level as possible. A check valve is necessary

for pumping from a drive point well where the suction line

is driven into the ground to extract the surrounding

groundwater. A foot valve is more suitable for a cased/

dug well. Either can be used for pumping from a lake or

stream, provided the end of the suction pipe is also

protected by a strainer. Special care should be taken to

ensure that all suction fittings are tight and sealed.

Otherwise, the pump cannot be primed or will lose prime

over a period of time.

1-1/4

”

Suction Pipe

Sanitary

Well Seal

Well

1-1/4

”

Foot Valve

Union