Printing |

33

Feature type

Minimum value

Notes

Pin diameter

0.8 mm/800 μm

A wire is a feature whose length is at least two times greater

than its width. Wires or pins with a diameter less than 0.8 mm

width may deform or break during the print. Take extra care

when separating printed parts with thin wires from the powder

cake, as they can easily be damaged.

Hole diameter

0.8 mm/800 μm

Holes with a diameter of less than 0.8 mm in the X-, Y-, and

Z-axes may close during printing. The accuracy of a hole not

only depends on the diameter of the hole, but also on the

thickness of the wall through which the hole is printed. The

thicker the wall section, the less accurate the hole will be.

Through holes must also allow for line-of-sight clearance to

ensure all material is cleared during post-processing.

Moving part

clearance

0.4 mm/400 μm

Clearance is the distance between two parts of a model (e.g.,

the distance between a pair of gears). Parts that are part of an

assembly may fuse if clearance is less than 0.4 mm.

5.3

Setting up a print

For detailed guidance and visual assistance, visit

support.formlabs.com

.

Fuse 1 print jobs can be set up using PreForm, the dedicated print preparation software for

Formlabs printers. To start, open OBJ or STL files in PreForm, orient and layout multiple models

into a complete build, then send the print job to the machine.

5.3.1

Downloading or updating PreForm

Visit the PreForm product webpage to download the latest version:

formlabs.com/software

.

Learn how to use PreForm from the tutorials available in the software. Click

Help

>

Show

Onboarding Tutorial

from PreForm’s menu bar.

5.3.2

Preparing the file for printing

Use PreForm software to process STL or OBJ files. Prepare, save, and upload FORM files to the printer.

5.3.2.1 Adding a model

Import multiple part files into PreForm to print multiple parts in a single build chamber.

To add a model:

1. In the menu bar, click

File

>

Open

. The

Open File

window opens.

2. Select at least one file.

3. Click Open . The selected models appear in PreForm.

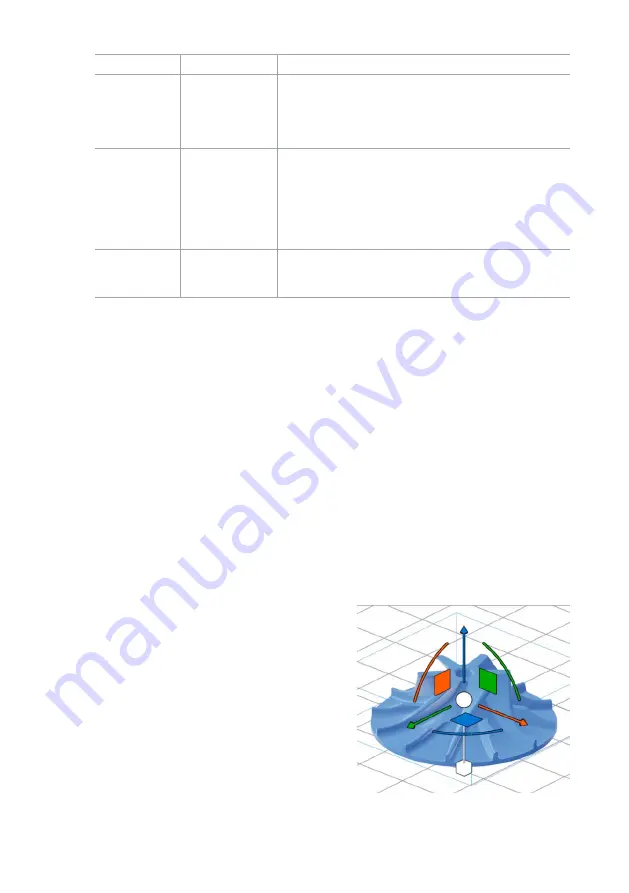

5.3.2.2 Orienting a model

The unsintered powder in the build chamber

inherently supports parts, regardless of their

orientation. However, depending on the

geometry of the parts being printed, certain

part orientations may minimize the visibility of

print layers or to pack parts more densely into a

complete print job.

To orient a model:

1. Select the model using the left mouse button.

Manipulators appear over the model.

Summary of Contents for Fuse 1

Page 1: ...Manual Fuse 1 ...

Page 2: ......

Page 6: ......

Page 64: ...Original English instructions January 2021 Formlabs ...