3-5

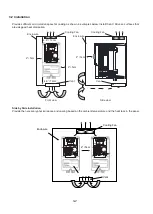

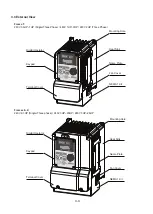

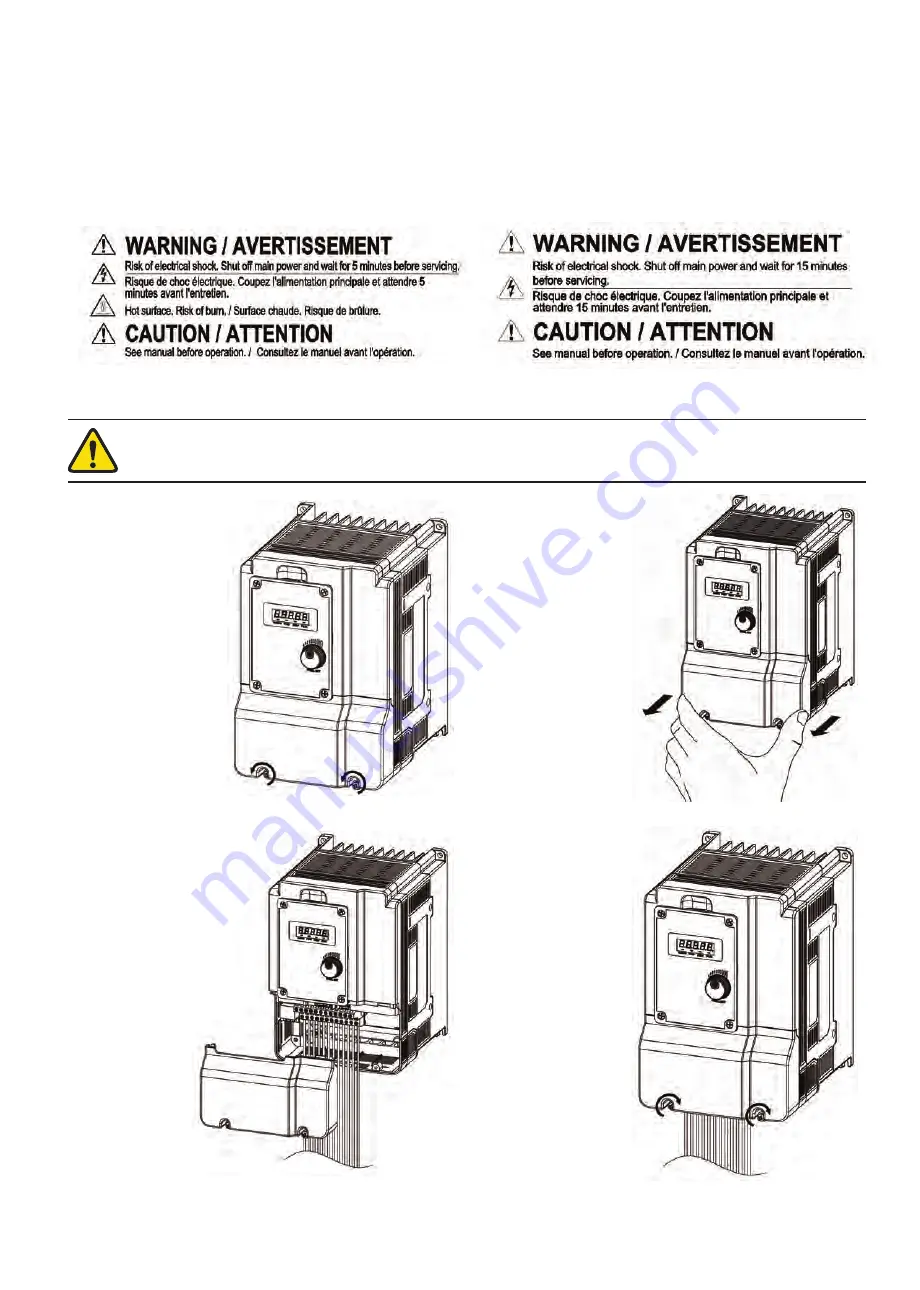

3.4 Warning Labels

Important:

Warning information located on the front cover must be read upon installation of the AC Drive.

240V 0.5HP–20HP / 480V 1HP–25HP

240V 25HP–40HP / 480V 30HP–75HP

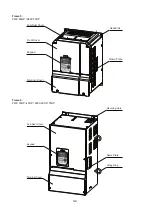

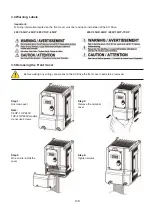

3.5 Removing the Front Cover

Before making any wiring connections to the AC Drive the front cover needs to be removed.

Step 1:

Unscrew cover

Note:

0.5HP–1HP 240V,

1HP–2HP 480V models

do not use screws.

Step 2:

Remove the terminal

cover

Step 3:

Wire and re-install the

cover

Step 4:

Tighten screws