EX355

T5-6-1

ELECTRICAL SYSTEM INSPECTION

PRECAUTIONS FOR INSPECTION AND

MAINTENANCE

1. Disconnect the power source.

Be sure to remove the negative terminals from the

batteries first when taking wire harnesses and

connectors off for repair or replacement work.

Failure to do so can result in damage to the wire

harnesses, fuses, and fusible links and, in some

cases, cause fire due to short circuiting.

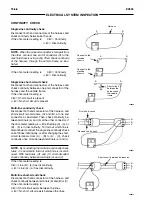

2. Wire harnesses identification.

The wire harnesses used on electrical system of

the machine are of three colours: red, white and

brown.

– The wire harnesses red coloured are used for

the main power supply distribution and for direct

connection to the positive not controlled by key

switch.

– The wire harnesses white coloured are used

for the all other functions.

– The wire harnesses brown coloured are used

for ground connection.

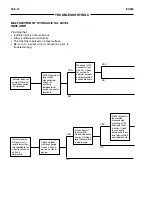

Each wire is identified by a four digit numerical

coding printed on the whole lenght every 20 to 30

mm (A).

This coding is also shown on the wiring diagrams of

electrical system (B).

On the general electrical system diagram attached,

numbers and letters are shown before the four digit

coding.

Numbers mean the wire section shown in mm

2

.

The following letters indicate the wire colours;

where W stands for white, R for Red and Br for

Brown. See detail (C).

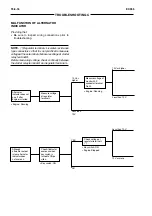

3. Precautions for connecting and disconnecting ter-

minal connectors.

1)

When disconnecting harnesses, grasp them

by their connectors. Do not pull on the wire

itself. Be sure to release the lock first before

attempting to separate connectors, if a lock is

provided. (Refer to “Instructions for Discon-

necting Connector” on page T5-6-3.)

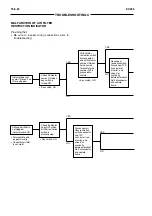

2)

Water-resistant connectors keep water out so

that if water enters them, water will not easily

drain from them. When checking water-resi-

stant connectors, take extra care not to allow

water to enter the connectors. In case water

should enter the connectors, reconnect only

after the connectors are thoroughly dried.

3)

Before connecting terminal connectors, check

that no terminals are bent or coming off. In

addition, as most connectors are made of

brass, check that no terminals are rusting.

4)

When connecting terminal connectors pro-

vided with a lock, be sure to insert them to-

gether until the lock “clicks.”

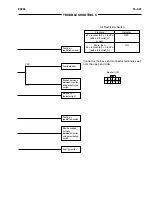

Right

Wrong

Right

Rust

Wrong

(deformation)

Wrong

(Separation)

SM0651

SM0652

A

0511

0511

0511

20 ÷ 30 mm

B

0511

0511

C

2.5 R 0679

Summary of Contents for EX355 Tier2

Page 22: ...T1 2 10 EX355 COMPONENT LAYOUT NOTES ...

Page 37: ...T2 1 14 EX355 CONTROL SYSTEM NOTES ...

Page 47: ...T2 2 10 EX355 HYDRAULIC SYSTEM NOTES ...

Page 73: ...T2 3 26 EX355 ELECTRICAL SYSTEM NOTES ...

Page 86: ...T3 1 12 EX355 PUMP DEVICE NOTES ...

Page 94: ...T3 2 8 EX355 SWING DEVICE NOTES ...

Page 134: ...T3 4 10 EX355 PILOT VALVE NOTES ...

Page 146: ...T3 5 12 EX355 TRAVEL DEVICE NOTES ...

Page 156: ...T3 7 4 EX355 OTHER COMPONENTS Undercarriage NOTES ...

Page 195: ...T4 2 6 EX355 STANDARD NOTES ...

Page 199: ...T4 3 4 EX355 ENGINE TEST NOTES ...

Page 215: ...T4 4 16 EX355 EXCAVATOR TEST NOTES ...

Page 237: ...T4 5 22 EX355 COMPONENT TEST NOTES ...

Page 265: ...T5 2 12 EX355 COMPONENT LAYOUT NOTES ...

Page 325: ...T5 4 52 EX355 TROUBLESHOOTING B ...

Page 372: ...EX355 T5 6 9 ELECTRICAL SYSTEM INSPECTION ...

Page 385: ...T5 6 22 EX355 ELECTRICAL SYSTEM INSPECTION NOTE ...

Page 425: ...W1 1 4 EX355 PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY NOTES ...

Page 450: ...W2 3 8 EX355 MAIN FRAME NOTES ...

Page 454: ...W2 4 4 EX355 PUMP DEVICE SM5510 ...

Page 456: ...W2 4 6 EX355 PUMP DEVICE SM5510 ...

Page 458: ...W2 4 8 EX355 PUMP DEVICE ASSEMBLE PUMP DEVICE SM6205 SM6206 ...

Page 460: ...W2 4 10 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 462: ...W2 4 12 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 464: ...W2 4 14 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 468: ...W2 4 18 EX355 PUMP DEVICE SM6210 ...

Page 470: ...W2 4 20 EX355 PUMP DEVICE SM6210 ...

Page 472: ...W2 4 22 EX355 PUMP DEVICE SM6210 ...

Page 474: ...W2 4 24 EX355 PUMP DEVICE SM5511 SM6219 ASSEMBLE MAIN PUMP ...

Page 476: ...W2 4 26 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 478: ...W2 4 28 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 480: ...W2 4 30 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 482: ...W2 4 32 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 484: ...W2 4 34 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 486: ...W2 4 36 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 498: ...W2 4 48 EX355 PUMP DEVICE NOTES ...

Page 532: ...W2 5 34 EX355 CONTROL VALVE NOTES ...

Page 540: ...W2 6 8 EX355 SWING DEVICE SM6277 31 18 17 20 19 21 3 24 27 25 26 10 ...

Page 542: ...W2 6 10 EX355 SWING DEVICE SM6277 31 19 2 1 23 22 ...

Page 566: ...W2 7 12 EX355 PILOT VALVE 11 19 17 18 1 2 3 8 13 14 16 15 SM1114 ...

Page 572: ...W2 7 18 EX355 PILOT VALVE 8 6 7 1 3 4 5 9 21 2 SM1119 ...

Page 586: ...W2 7 32 EX355 PILOT VALVE NOTES ...

Page 592: ...W2 8 6 EX355 PILOT SHUT OFF VALVE NOTES ...

Page 602: ...W2 10 6 EX355 SOLENOID VALVE UNIT NOTES ...

Page 621: ...W3 2 10 EX355 TRAVEL DEVICE SM5108 44 8 13 12 1 45 46 28 27 25 26 24 36 38 30 31 32 ...

Page 627: ...W3 2 16 EX355 TRAVEL DEVICE SM5502 3 4 5 20 7 8 9 10 12 14 13 16 11 6 ...

Page 643: ...W3 2 32 EX355 TRAVEL DEVICE NOTES ...

Page 651: ...W3 3 8 EX355 CENTER JOINT NOTES ...

Page 655: ...W3 4 4 EX355 TRACK ADJUSTER 8 14 13 11 17 12 SM6284 ...

Page 657: ...W3 4 6 EX355 TRACK ADJUSTER 3 4 8 10 16 15 14 SM6284 ...

Page 659: ...W3 4 8 EX355 TRACK ADJUSTER 3 6 4 8 10 9 SM6284 18 ...

Page 667: ...W3 4 16 EX355 TRACK ADJUSTER NOTES ...

Page 671: ...W3 5 4 EX355 FRONT IDLER 1 SM6290 2 4 3 5 6 8 12 7 6 3 4 1 2 9 10 11 ...

Page 689: ...W3 6 14 EX355 UPPER AND LOWER ROLLER NOTES ...

Page 708: ...W4 1 10 EX355 FRONT ATTACHMENT NOTES ...

Page 716: ...W4 1 18 EX355 FRONT ATTACHMENT NOTES ...

Page 744: ...W4 2 28 EX355 CYLINDERS NOTES ...

Page 763: ...EX355 W5 1 17 GENERAL INFORMATION Oil Pan N m kgf m Ib ft SM7010 ...

Page 765: ...EX355 W5 1 19 GENERAL INFORMATION Water Pump N m kgf m Ib ft SM7012 ...

Page 815: ...EX355 W5 3 35 ENGINE OVERHAUL Disassembly SM7093 1 Camshaft gear 2 Knock pin 3 Camshaft ...

Page 883: ...EX355 W5 3 103 ENGINE OVERHAUL Reassembly 1 Crankshaft 3 Crankshaft gear 2 Pin SM7239 ...

Page 894: ...W5 3 114 EX355 ENGINE OVERHAUL NOTE ...

Page 938: ...W5 7 6 EX355 ENGINE INDUCTION NOTE ...