Ferm

65

OPERATION

Before setting up, repair or maintenance of the

appliance you must always turn off the operating

switch and pull out the mains plug!

Before initial operation

-

Check if the rated voltage and rated frequency of the

mains supply correspond to the details of the type

plate.

-

Place the workbench on a stable and even base.

Operation

-

To adjust the planing depth, turn the control knob

(Fig. 1, A) in a clockwise direction. On the control

knob there is a pointer (Fig. 1, A) which shows the

planing depth in mm. Turn the control knob until the

desired planing depth is shown.

Never alter the planing depth during an operating

cycle, otherwise this will result in an uneven

surface. To prevent operating errors turn the control knob

back to “0” when planing is completed.

-

Secure the work piece with clamps or similar.

-

Place the front sole on the edge of the work piece in

such a way that the planing tool does not yet touch

the work piece. The work piece must be level.

-

Now insert the mains plug into the socket. To switch

on, first press the release button (Fig. 1,E), keep it

pressed down while you press the operating switch

(Fig. 1,D). The appliance is now switched on and you

can let go of the release button.

-

When the machine has reached full speed it can be

pushed to the front over the work piece. At the

beginning of the planing operation, put some

pressure on the front and at the end of the operation,

on the rear of the appliance. This results in the

appliance remaining flat on the work piece and

prevents the corners from getting rounded off.

-

To obtain a level and smooth surface use a greater

planing depth when rough planing and a lesser planing

depth when planing a layer. Hold the electric tool

straight during the operation, otherwise you will

obtain an uneven surface. After the operation switch

off the electric tool and remove the mains plug.

WARNING!

1. Take care that your hand never comes in contact

with the work piece during the operation.

2. Only use the electric plane on the upper side of the

work piece, never from below or from the side.

3. Store the appliance only after it has come to a

complete standstill.

-

Use a suction device to suck off wood shavings or

dust. For this use the connecting pipe

and connect a suction pipe to it.

-

Use a holding device to work on small work pieces.

CARE AND MAINTENANCE

Before undertaking any care or maintenance

always remove the mains plug from the socket.

The planing tool becomes worn after a period of

operation. If you use a blunt or damaged planing tool

operational efficiency is reduced and the electric motor

might become overloaded. Check the planing tool

regularly with regard to wear or damage. Depending on

its condition, the planing tool will have to be replaced.

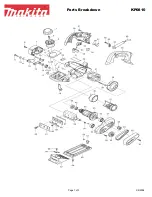

REMOVAL OF PLANE BLADE (FIG. 2)

Use the enclosed open-jawed spanner (Accessories).

First unscrew the three clamping screws (6) with the

open-jawed spanner and remove the plane blade (3), the

plane blade holder (2) and the plane blade support (4)

from the holding shaft (1).

INSTALLATION OF PLANE BLADE (FIG. 2)

Take the new plane blade (3) and position it between the

plane blade support (4) and the plane blade holder (2).

Now turn the clamping screws (6) as far as possible into

the plane blade support.

But not so far that the plane blade and the plane blade

holder become detached again from the plane blade

support. Afterwards put the plane blade, plane blade

holder and plane blade support together into the holding

shaft. The plane blade support, plane blade and plane

blade holder will now be fastened together in the holding

shaft by releasing the clamping screws with the open-

jawed spanner and thus the plane blade, plane blade

support and plane blade holder are clamped in position.

ATTENTION:

Unscrew clamping screws as fas as possible so that a

sufficient attachment is ensured.

WARNING!

1. When installing and removing the plane blade, care

has to be taken that all parts (plane blade, plane blade

holder, plane blade support and holding shaft) are

clean. Dirt or possible existing layers of dirt have to

be removed.

2. The Allen screws (5) are secured with an adhesive.

These screws must not be adjusted. The position of

these screws may only be altered by the

manufacturer!

Check regularly if the clamping screws are

tightened firmly. Always tighten screws firmly.

REPLACEMENT OF THE CARBON BRUSHES

The carbon brushes can become worn after frequent

use. A regular check after about every 100 running hours

is therefore necessary. If the carbon brushes are shorter

than 4 mm then these will have to be replaced with new

ones.

-

Remove the cover on the right.

-

Take out the carbon brushes and check these.

-

Replace the carbon brushes.

-

Replace the two screws and screw them tight.

4

Ferm