Series ’90 Hot Deli

Page

8

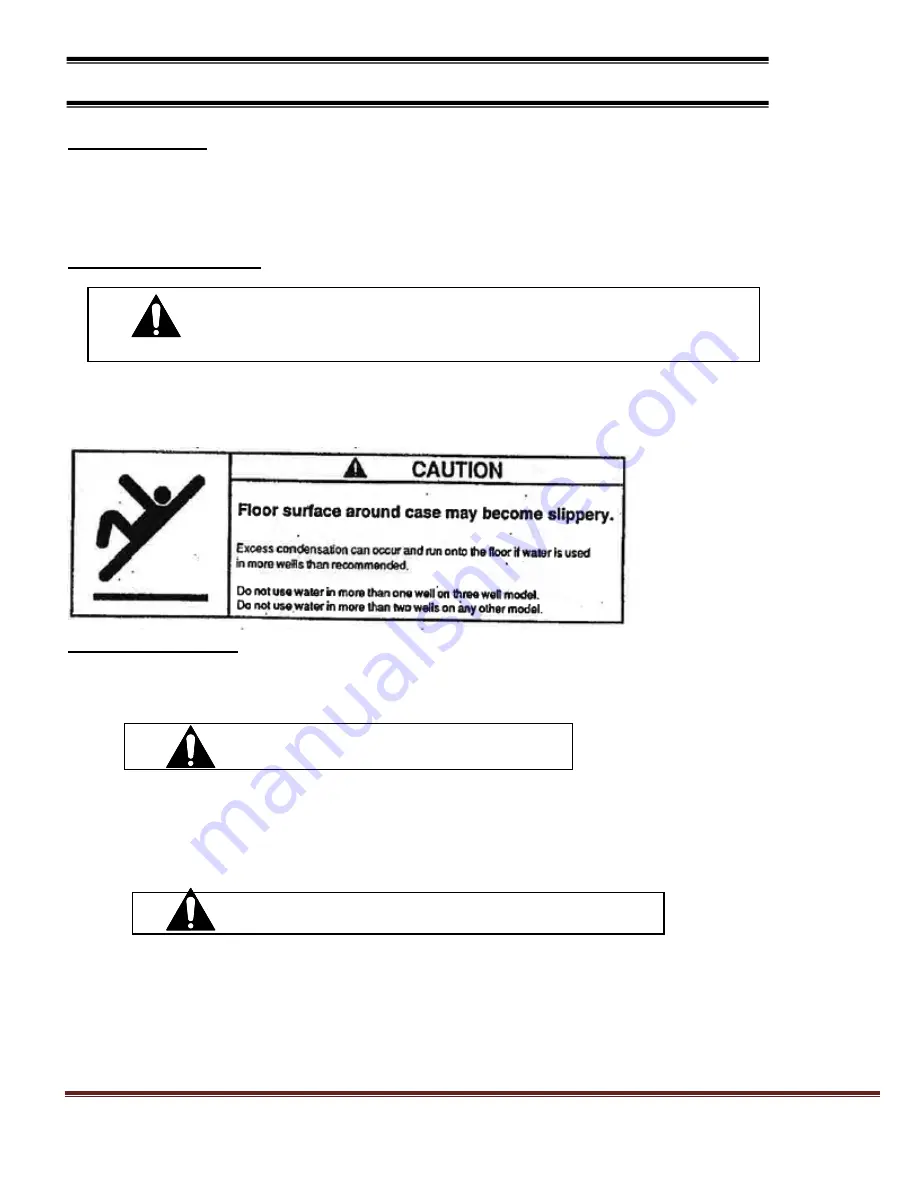

NOTICE:

This case should not be operated with water in all the wells.

Excess condensation can occur and run onto the floor

creating a slip/fall hazard around the case.

NOTICE:

Never allow wet wells to boil

NOTICE:

Never pour water into a heated, dry well.

OPERATING INSTRUCTIONS

Initial Start-Up

After all the checks outlined in the installation section of this manual have been made, the case is ready to be

put into service.

The case should be cleaned thoroughly before it is used for the first time.

Operating Guidelines

In operation, do not use water in more than one well. Using water in more wells than recommend will cause

excessive condensation that can run onto the floor and create a slip/fall hazard around the case.

Operation of Wells

The case will keep many products at the proper temperature without the use of water. The type of food

product being kept in the case is the determining factor as to whether water is used in the well. Any product

that can be run dry should be held in a dry well to prevent excessive condensation from forming on the glass.

Never allow wet wells to boil. A water temperature for 180F to 190F is recommended. The water level in a

wet well should always be high enough to touch the bottom of the pan holding the product.

The overhead infrared heater should be on when food product is being kept in the case. The heater helps to

maintain proper product temperature and prevents front glass from fogging.

Close the well drain valves located in the lower compartment for any well(s) to be run wet. Fill any well(s) to

be run wet with three to four inches of water utilizing the plumbed water supply or fill manually. The water

lever in a wet well should always be high enough to touch the bottom of the pan holding the product.