77

6.7 Malfunction and troubleshooting

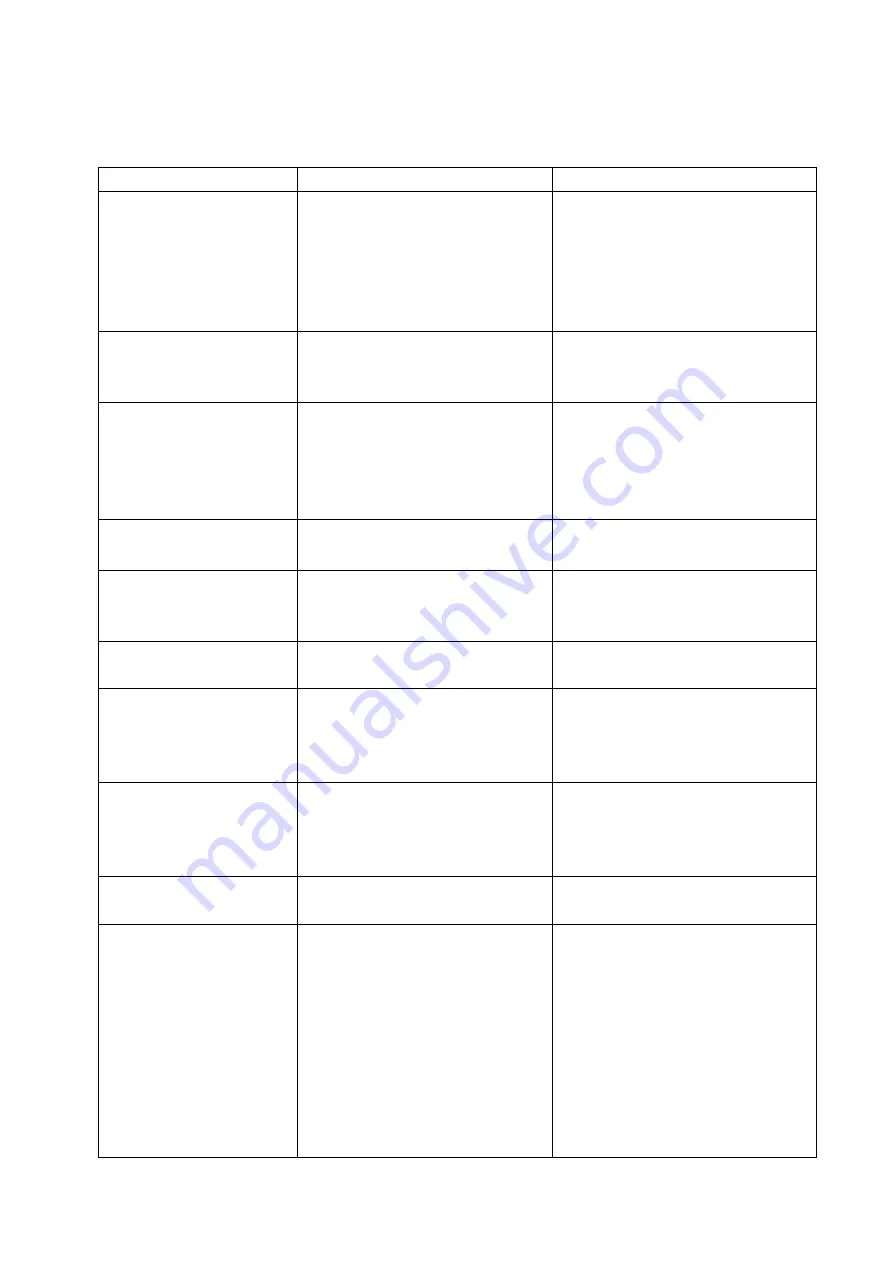

Table 6-6 Malfuction and troubleshooting

Trouble

Causes

Solution

1. Temperature of extruder

barrel fails to reach the

required temperature.

Steam conditioning temperature is low.

Steam pipeline of Jacket is blocked.

The inlet of steam pipeline in extrude

barrel is blocked

Raise conditioning temperature to make

material temperature to 80

℃

-90

℃

after

conditioning

Clean the steam pipeline of jacket.

Clean the steam pipeline into extruder

barrel.

2. Temperature of conditioning

fails to meet the requirement.

Steam pressure is not sufficient

Steam pipeline is blocked

Check steam pressure.Adjust it to normal

4bar.

Clean the steam pipeline

3. Products look rough with

uneven lengths.

Poor conditioning.

Some die plate holes are blocked

Ground particle size too coarse

Bad quality of die plate.

Enhance material conditioning.

Stop production and clean the die plate.

Improve grinding for finer particles.

Use the die plate made by the reputable

manufacturer.

4.Throughput decreases

Pressure ring or wear ring is worn out;

Screw head is seriously worn out.

a) Replace wear ring or pressure ring

b) Replace screw head

5.Material

cannot

be

discharged in a sudden during

normal operation

Excessive feeding in short-time or

feeding cut-off.

Blocked die holes.

Stop production to check and correct.

6.Uneven

intermittent

discharge

Low filling degree of extruder barrels

Increase feeding.

7.Insufficient expansion

Insufficient gelatinization

Increase feeding.

Raise conditioning temperature.

Raise jacket heating temperature.

Increase rotary speed of main motor.

8.Excessive expansion

Excessive temperature

Rotation speed of main motor too high.

Opening area of die plate does not

match the output

Decrease temperature.

Reduce the rotating speed.

Change the open area of die plate or

adjust the output.

9.Product length too long or

too short

Cutter speed too low or too high

Adjust the cutting transmission speed

10.Poor product forming

Improper raw material formula

Processing temperature too high or too

low.

Unstable feeding

Product moisture content too high or too

low.

Incorrect cutting speed.

Blade is worn out.

Ground particles too coarse.

Change formula of raw materials

Reconfigure the components in machine

barrels.

Adjust to even feeding.

Reduce or increase water or steam

addition.

Adjust the rotating speed appropriately.

Replace blade.

Grind the raw materials to obtain the

defined granularity.