35

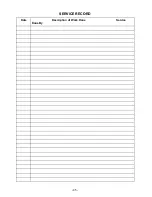

FIGURE 14

THROTTLE TENSION

5.2.8

Electric Clutch Adjustment:

No adjustment necessary.

5.2.9

Reverse Indicator Adjustment:

a) Stop engine, wait for all moving parts to stop, and remove key.

b) Unhook seat latch and tilt seat forward.

c) Begin with either the left or right motion control lever. Move lever to the

neutral position and pull lever back until the clevis pin (on arm below pivot

shaft) contacts the end of the slot (just beginning to put pressure on

spring), See Figure 15.

d) Check where lever is relative to notch in console (should be centered

allowing lever to pivot outward to the neutral lock position).

e) If adjustment is needed, loosen the nut against the yoke and while applying

slight rearward pressure on the motion control lever, turn the head of the

adjustment bolt in the appropriate direction until lever is centered (keeping

rearward pressure on the lever will keep the pin at the end of the slot and

allow the adjustment bolt to move the lever to the appropriate position).

Tighten lock nut.

f)

Repeat on opposite side of unit.

5.2.10

Motion control linkage adjustment.

WARNING

POTENTIAL HAZARD

♦

Engine must be running and drive wheels must be

turning so motion control adjustment can be performed.

WHAT CAN HAPPEN

♦

Contact with moving parts or hot surfaces may cause

personal injury.

HOW TO AVOID THE HAZARD

♦

Keep fingers, hands, and clothing clear of rotating

components and hot surfaces.

Summary of Contents for Laser Z CT

Page 1: ...For Serial Nos 540 000 Higher Part No 103 9180 ...

Page 45: ...40 8 BRIGGS STRATTON ELECTRICAL DIAGRAM ...

Page 46: ...41 9 HYDRAULIC DIAGRAM ...

Page 48: ... 43 NOTES ...

Page 49: ... 44 NOTES ...

Page 50: ... 45 SERVICE RECORD Date Description of Work Done Service Done By ...

Page 51: ... 46 ...