66

04-2017 5325 00

7. Reassemble the powder drawers and

the powder funnels after having carefully

rinsed and dried them.

8. Reposition the mixer.

Check that the water funnel has been

correctly inserted.

Fig. 44

9. Turn the water funnel locking ring anti-

clockwise in order to secure the mixer to

the appliance.

After reassembling the components, it

is necessary to:

Wash the mixer and add a few drops of the

sanitising solution into the various funnels

and rinse thoroughly to remove any resi-

dues from the solution that has been used.

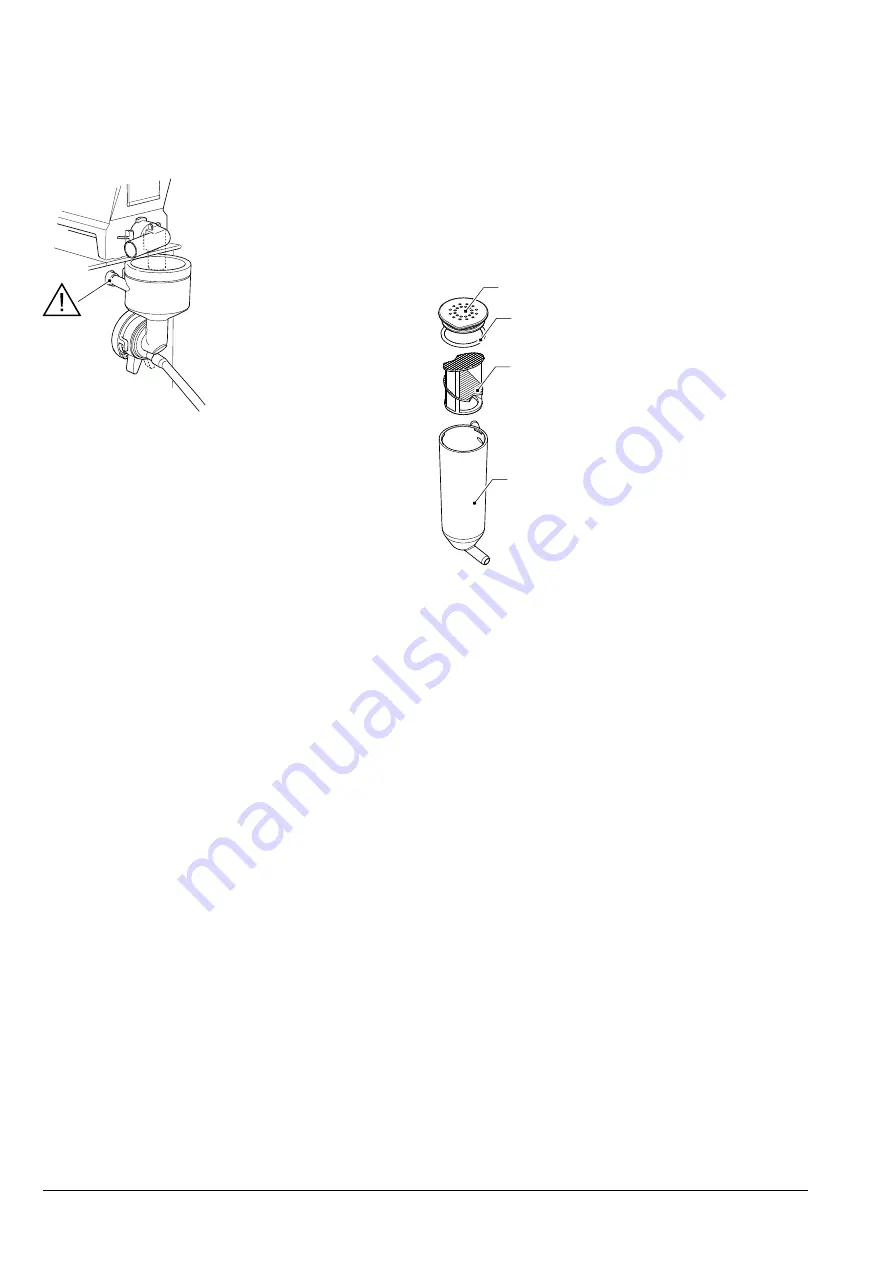

DiffusEr

NozzlE

For models with the Z4000 ESFB brewing

unit only.

1. Unhook the diffuser nozzle from the sup-

port bracket.

2. Separate the diffuser nozzle compo-

nents.

3. Check that the seal does not have any

tears or has not lost its elasticity; if nec-

essary, replace it.

3

2

1

4

Fig. 45

1. Cover

2. Seal

3. Diffuser

4. Diffuser nozzle body