43

【

Retrieving and input of calibration value

】

1. Connect APH550 and the PC.

2. Start up the hyper terminal and match the

setting of the PC with the one of APH550.

※

The setting procedures of the hyper terminal.

①

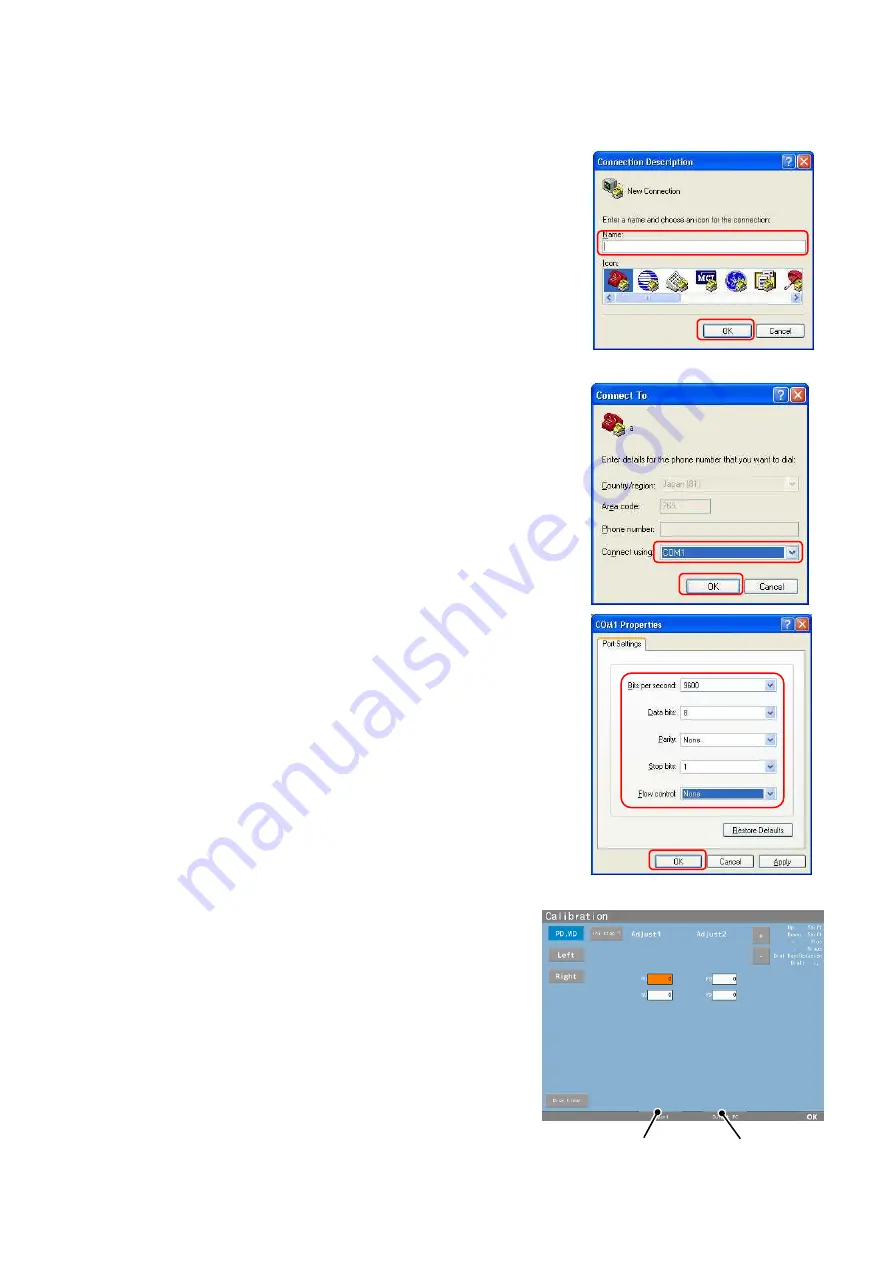

Start up the hyper terminal of PC, input

the setting name in “Name” and press “OK”.

②

Select the port which connects the cable

from “Connect using” and press “OK”.

③

Set the details of “Port Settings” same

with the ones of APH550 and press “OK”.

Setting of APH550

Bits per second :9600 or 115200

Data bits

:8

Parity

:None

Stop bits

:1

Flow control

:None

3. Press the “Output PC button”.

The data is output to the PC.

4. Save the output data as the text data.

5. Overwrite and save it after matching the

saved data values with the values for the

repair parts.

Output PC button

Import button

Summary of Contents for APH 550

Page 1: ...Automatic Phoropter Maintenance Manual V1 09 2016...

Page 9: ...7 3 Connection Diagram...

Page 10: ...8...

Page 78: ...76...