6 TIG WELDING

0460 896 274

- 38 -

© ESAB AB 2013

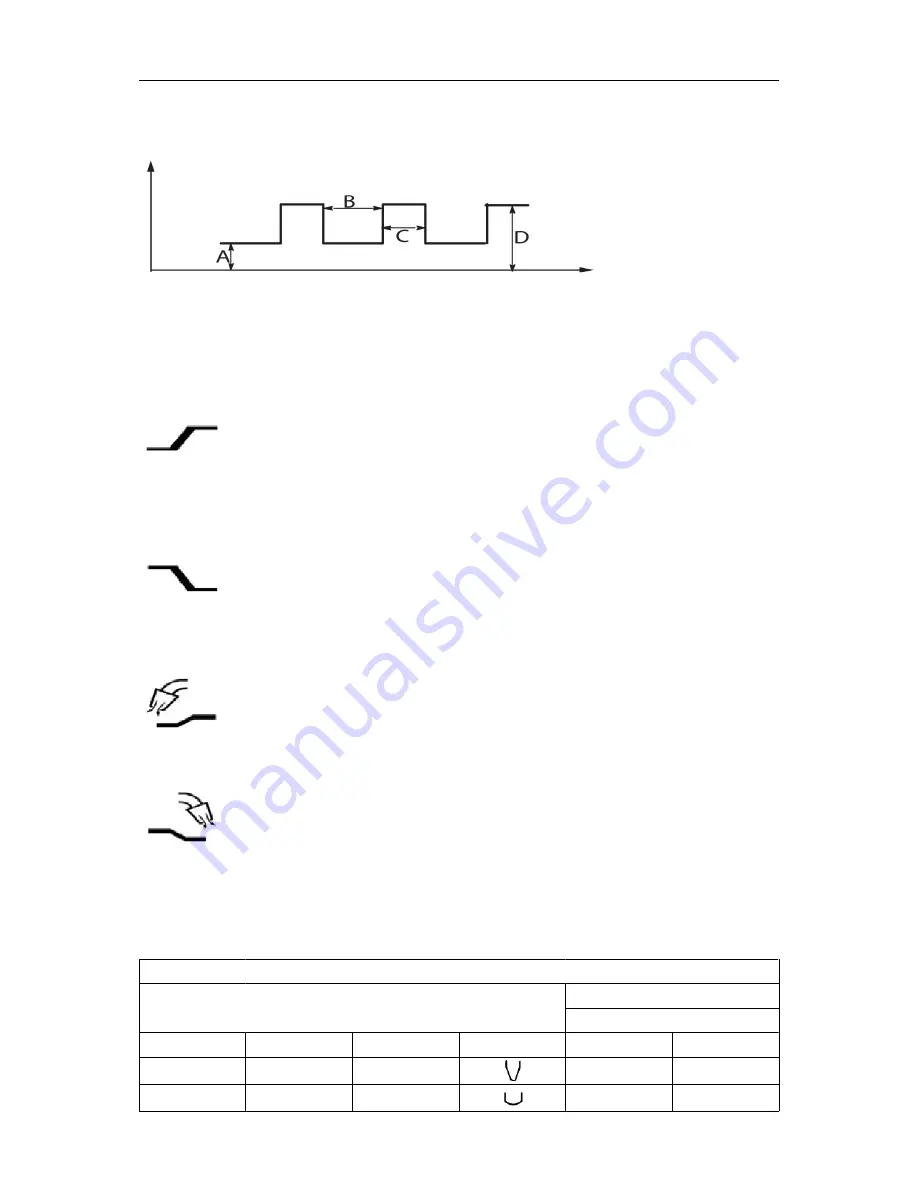

Current

Time

TIG welding with pulsing.

A = Background current

B = Background time

C = Pulse time

D = Pulse current

Slope up

The slope up function means that, when the TIG arc strikes, the current rises

slowly to the set value. This provides `gentler' heating of the electrode, and

gives the welder a chance to position the electrode properly before the set

welding current is reached.

Slope up is set in the weld data setting menu.

Slope down

TIG welding uses “slope down”, by which the current falls 'slowly' over a

controlled time, to avoid craters and/or cracks, when a weld is finished.

Slope down is set in the weld data setting menu.

Gas pre-flow

This controls the time during which shielding gas flows before the arc is struck.

Gas pre-flow is set in the weld data setting menu.

Gas post-flow

This controls the time during which shielding gas flows after the arc is

extinguished.

Gas post-flow is set in the weld data setting menu.

Automatic start pulse

This function is used to achieve a stable arc rapidly.

Preheating

Tungsten electrode

Setting value

Shielding gas

Ø

Colour

Type

Ar

Ar + 30% He

1.6

Green

WP

-

-

1.6

Green

WP

30

35

Summary of Contents for Aristo U82

Page 1: ...Aristo Instruction manual 0460 896 274 GB 20130902 Valid from program version 1 15A U82 ...

Page 80: ...MENU STRUCTURE 0460 896 274 80 ESAB AB 2013 MENU STRUCTURE ...

Page 81: ...MENU STRUCTURE 0460 896 274 81 ESAB AB 2013 ...

Page 82: ...MENU STRUCTURE 0460 896 274 82 ESAB AB 2013 ...

Page 83: ...MENU STRUCTURE 0460 896 274 83 ESAB AB 2013 ...

Page 84: ...MENU STRUCTURE 0460 896 274 84 ESAB AB 2013 ...