EPSON Perfection 4490 Photo

Revision B

OPERATING PRINCIPLES

Digital ICE Function Operation

23

2.2 Digital ICE Function Operation

This scanner features Digital ICE for Film, an image correction process that uses a

combination of hardware and software to detect and eliminate physical flaws, dust or

dirt, either on the Film or the scanner itself.

(Film includes color or monochrome

negative, and color positive.)

2.2.1 Digital ICE for Film Overview

Because of its longer wavelength, infrared light normally passes completely through

film media, such as negatives or slides, during a scan. Physical flaws or dust, however,

do block infrared light. When a film document with dust or physical flaws is scanned

using infrared light, the light is physically blocked by the flaw or dust, and the resulting

image clearly shows only the dust and/or flaws present. By superimposing the images

scanned with infrared light and visible light, the Film-ICE software is able to detect the

inconsistency in the digitized data caused by the flaw and automatically remove it

using interpolated image data to overwrite and correct the image. Because of the

difference in wavelength between infrared light and visible light, a secondary lens

("Glass Plate" in the images below) must be employed during the Film-ICE visible-

light scan to compensate for the resulting difference in the size of the images so that

they can be superimposed accurately. The Glass Plate is moved into and out of position

by a solenoid.

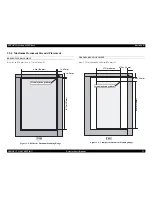

Figure 2-7. Refraction of Infrared Light and Visible Light

Digital ICE for Film Process Sequence

1. Read the visible light position. Two holes in the upper housing are scanned with

visible light in order to register the home position of image being scanned.

2. Move the secondary lens (Glass Plate) into position and scan the film in visible-

light.

3. Retract the secondary lens and scan the film in infrared-light.

4. Electronically superimpose the images obtained from each light source and

identify the physical flaws and/or foreign matter.

5. Replace the "flaw" image data with image data interpolated from adjacent areas.

Figure 2-8. Extraction/Correction of Dust by Film-ICE Function

Lens

CCD

Glass

Plate

Infrared

Light

Lens

CCD

Glass

Plate

Visible

Light

Dirt

on

the

Slide

After

Correction

Summary of Contents for Perfection 4490 Photo

Page 8: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 18: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 25: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 29: ...C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 57: ...C H A P T E R 5 ADJUSTMENT ...

Page 59: ...C H A P T E R 6 MAINTENANCE ...

Page 63: ...C H A P T E R 7 APPENDIX ...

Page 66: ...Model GT X750 Perfection 4490 Photo Board Main Board Rev A Sheet 1 1 ...

Page 68: ...Model GT X750 Perfection 4490 Photo Board DRV Board Assy Rev A Sheet 1 1 ...

Page 69: ...Model GT X750 Perfection 4490 Photo Board Image Sensor Board Rev B Sheet 1 1 ...

Page 70: ...Model GT X750 Perfection 4490 Photo Board SUB Board Rev A Sheet 1 1 ...

Page 71: ...Model GT X750 Perfection 4490 Photo Board SUB C Board Rev A Sheet 1 1 ...

Page 72: ...Model GT X750 Perfection 4490 Photo Board SUB D Board Rev A Sheet 1 1 ...

Page 74: ...GT X750 Perfection 4490 Photo NO 1 Rev 02 B176 ACCE 0012 10 20 30 40 400 401 ...

Page 76: ...R ev 01 B176 CAS E 002 GT X750 Perfection 4490 Photo NO 3 110 111 101 102 ...