Milling programming:

Once the milling tool is installed in the machine, the robot welding gun and the milling process

are as follows:

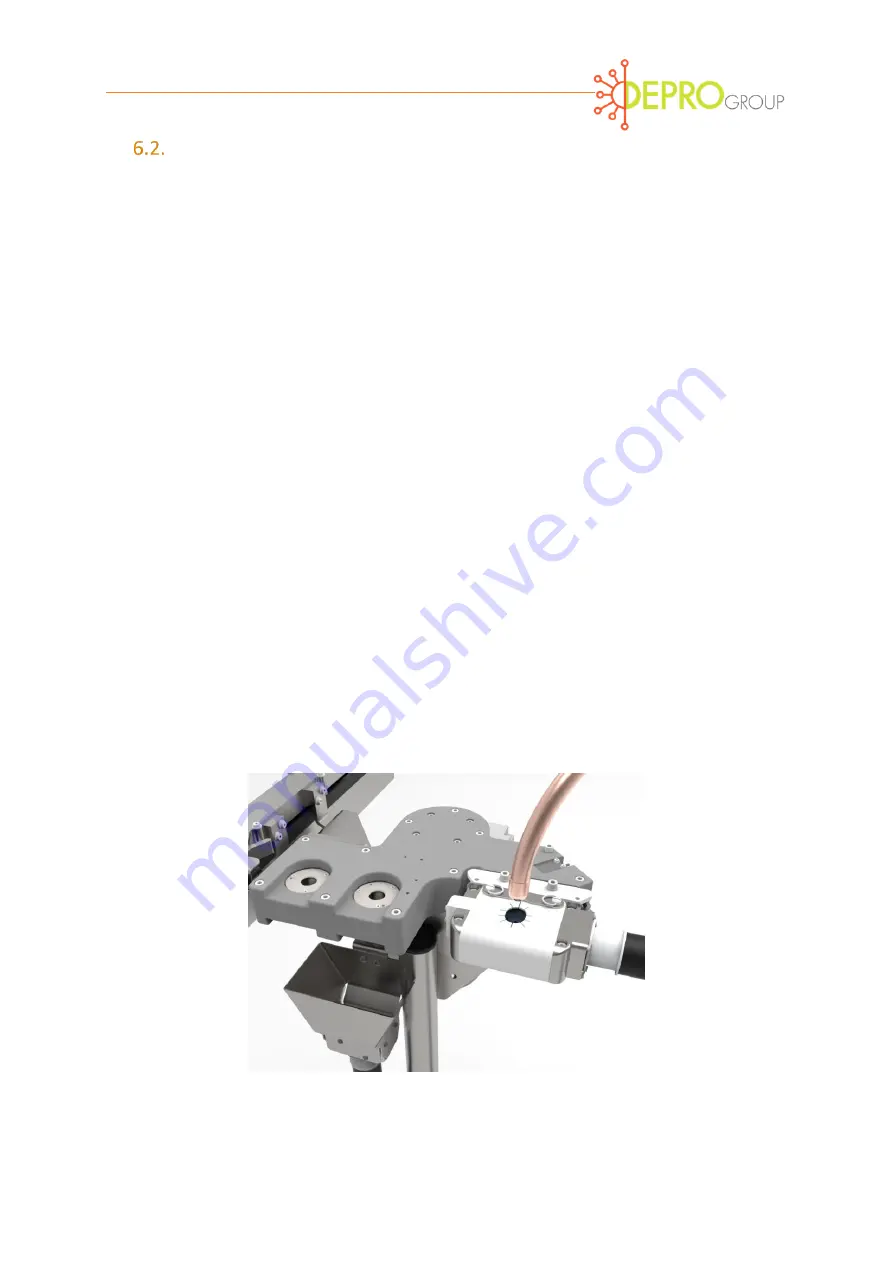

The welding electrodes are adjusted linearly to each other and to milling device as in

the welding position (figure 10). When using a C-guns at least one electrode should be

90 degrees to the electrode cutter.

The closing force for milling with Quattro blade tools is 1.5 kN (337.2 lbf) and single

cutting tools is 1 kN (224.8 lbf) (basic setting). Based on this value, the milling result

(material removal) can be optimized later.

The milling time is approx. 2 seconds. This value also can be changed later when

optimizing.

The milling tool should rotate before closing and after opening the welding gun. A lead

time of two seconds before and five seconds afterwards is recommended. During the

post milling process, chips are removed by blow-off and transported into the collection

container. Depending on the extent of the milled contaminants, the post milling

process can be increased up to ten seconds to accommodate additional blow-off.

During the milling operation the welding current must be disengaged as it can damage

the tool.

Figure 10 Position of the electrodes to the milling tool