82

REV. 07/2019

HYDRAULIC SYSTEM

7

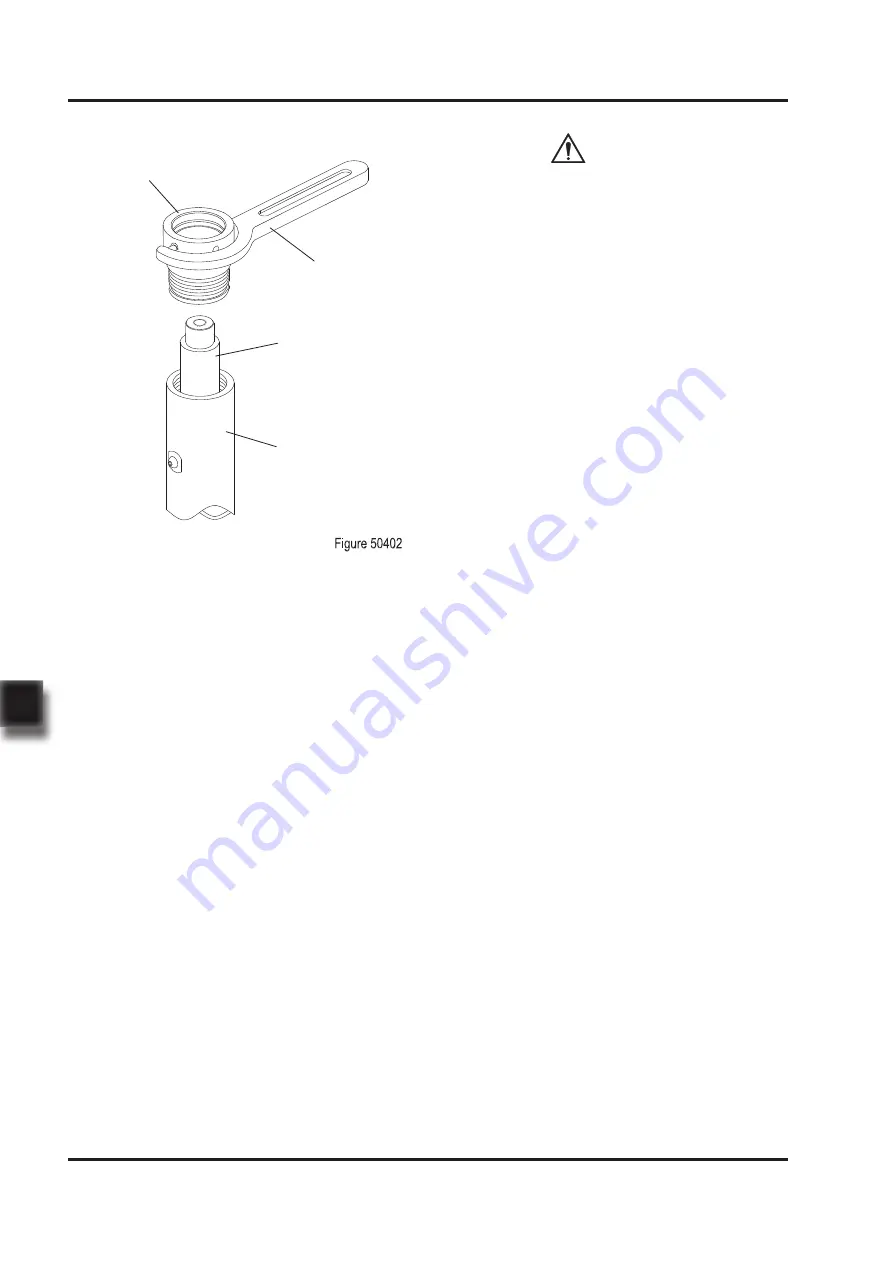

Cylinder Cap

Cylinder Wrenches

Piston Rod

Cylinder Tube

*

See Appendix A - Service Manual - Mast for

the removal of lift cylinder.

-

-

-

O-ring is quite flexible and easy to install,

but it must not be pulled up to the extent of

permanent deformation, nor scroll it while

installing;

Y-ring or X-ring needs to be identified if it is

for shaft or hole to avoid misplacement;

The removed O-rings and dust rings should

be replaced with new ones.

-

-

Cylinder parts must not be arbitrarily repla-

ced, the original products provided by the

manufacturer should be used;

After maintenance and assembly of the cylin-

der is completed, pressure leak testing must

be carried out before it can be put operation

once again.

Before the testing, discharge the air within

the cylinder, run the cylinder in a small range

of movement for several times, and pay

attention if it is moving without blocking and if

there is uneven resistance during the moving.

Upon the pressure testing, raise the pressure

slowly and observe carefully for leaks.

-

-

7.6.2 Cylinder Installation Precautions

All parts should be cleaned up before asse-

mbly, then to be assembled after being

dried;(during assembly, apply appropriate

amount of hydraulic oil for lubrication)

The tools used to install the seals must

be made of soft metal or suitable plastic,

without burrs and sharp edges on surfaces.

It is prohibited to use the tools that can

easily damage the surface of seals, such as,

screwdriver or other similar tools with hard

front edges.

Where the hydraulic seals to be installed

should be free of burrs, sharp edges and

cracks. If the installation of seals needs to

cross sharp edges, grooves or cuts, protective

devices must be used for protection. Before

installing, lubrication should be performed to

the seals and the mounting positions first with

hydraulic oil.

*

See Appendix A - Service Manual - Mast for

the installation of lift cylinder.

CAUTION

Summary of Contents for LIST JX0

Page 1: ...Service Manual JX0 Task Support Vehicle...

Page 2: ...Service Manual Task Support Vehicle JX0...

Page 14: ...1 1 1 INFORMATION SPECIFICATIONS...

Page 15: ...2 NOTE...

Page 23: ...10 2 2 MAINTENANCE...

Page 24: ...11 NOTE...

Page 34: ...21 3 3 STRUCTURE FUNCTIONS...

Page 35: ...22 NOTE...

Page 45: ...32 4 4 CHASSIS SYSTEM...

Page 46: ...33 NOTE...

Page 50: ...37 5 5 DRIVE SYSTEM...

Page 51: ...38 NOTE...

Page 68: ...55 6 6 OPERATING SYSTEM...

Page 69: ...56 NOTE...

Page 83: ...70 7 7 HYDRAULIC SYSTEM...

Page 84: ...71 NOTE...

Page 86: ...73 REV 07 2019 HYDRAULIC SYSTEM 7 7 1 1 Hydraulic Schematic Diagram...

Page 99: ...86 8 8 ELECTRICAL SYSTEM...

Page 100: ...87 NOTE...

Page 130: ...REV 07 2019 ELECTRICAL SYSTEM 8 117 operational...

Page 169: ...REV 07 2019 ELECTRICAL SYSTEM 8 156 8 16 Electrical Schematic Diagrams...

Page 170: ...REV 07 2019 ELECTRICAL SYSTEM 8 157...

Page 172: ...REV 07 2019 ELECTRICAL SYSTEM 8 159...

Page 173: ...160 9 9 TROUBLESHOOTING...

Page 174: ...161 NOTE...

Page 179: ...166 APPENDIX...

Page 180: ...167 NOTE...

Page 181: ...168 A A SERVICE MANUAL MAST...

Page 182: ...169 NOTE...

Page 185: ...172 REV 07 2019 SERVICE MANUAL MAST A...

Page 187: ...174 REV 07 2019 SERVICE MANUAL MAST A...

Page 190: ...177 B B SERVICE MANUAL BATTERY...

Page 191: ...178 NOTE...

Page 204: ...191 C C SCHEDULE...

Page 205: ...192 NOTE...