36

Enertech Global

IOM, BS/BT Models

Section 6: Unit Piping Installation

APSMA Pump Sharing Module

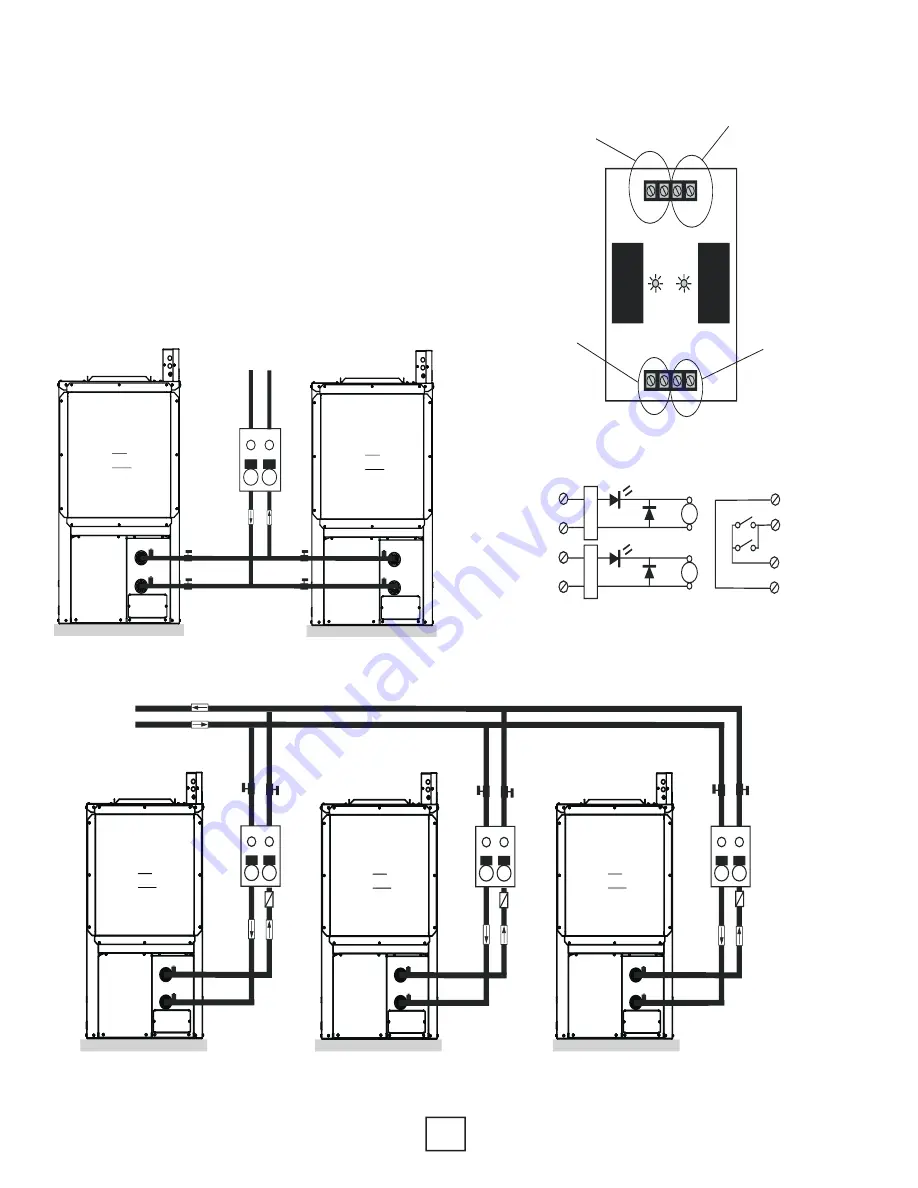

The pump sharing module, part number

APSMA, is designed to allow two units to share

one flow center. With the APSMA module,

either unit can energize the pump(s). Connect

the units and flow center as shown in the example

below. Figure 21 includes a schematic of the board.

The module must be mounted in a NEMA enclosure

or inside the unit control box.

Local code supersedes any recommendations

in this document.

Flow

Center

Hose

Kit

Loop Field

P/T Ports

air

coil

Source Out

Source In

P/T Ports

P/T Ports

air

coil

Source Out

Source In

P/T Ports

~

~

Shut O

ff

Valves

Shut O

ff

Valves

Equipment Pad

2” Polyethylene Foam

Equipment Pad

2” Polyethylene Foam

Single Shared Flow Center. Dual Unit Piping

Example:

Flow

Center

Loop Field

P/T Ports

air

coil

Source Out

Source In

P/T Ports

~

Shut O

ff

Valves

Flow

Center

P/T Ports

air

coil

Source Out

Source In

P/T Ports

Shut O

ff

Valves

Flow

Center

P/T Ports

air

coil

Source Out

Source In

P/T Ports

Shut O

ff

Valves

~

Check

Valve

Direction

of Flow

Check

Valve

Check

Valve

Direction

of Flow

Direction

of Flow

of Flow

Equipment Pad

2” Polyethylene Foam

Equipment Pad

2” Polyethylene Foam

Single Shared Loop Field, Individual Flow Center and Unit Piping Example

Drawing represents typical unit installation, connection location, type and appearance may differ per other

models

+

-

DC

Bridge

LED

Diode

RY1

24VAC input

from unit #1

+

-

Diode

RY2

24VAC input

from unit #2

RY1

RY2

240VAC input

240VAC to pump(s)

24VAC 24VAC

Figure 2: Board Schematic

240V IN 240V OUT

Relay

Relay

240VAC

Power Source

240VAC

to Pump(s)

24VAC

connection

to unit #2

(Y1 & C From Thermostat)

24VAC

connection

to unit #1

(Y1 & C From Thermostat)

Figure 21: APSMA Module Layout

Figure 22: APSMA Module Wiring Schematic