33

IOM, BS/BT Models

Enertech Global

•

It may be necessary to add some water into

the reservoir to keep the water level above the

return tee so that the solution does not foam.

•

The system must be run for 3 to 4 hours to mix

the antifreeze and water in the reservoir. The

fluid will not mix inside the loop.

•

Check the antifreeze level every so often to

insure that the proper amount was added to the

system (see antifreeze charging section).

Step 4: Final Pressurization of System

Once all of the air and debris has been removed,

and the antifreeze has been added and mixed, the

system is ready for final pressurization.

•

Turn one of the 3-way valves so that it is open

to all 3 ports, the unit, loop, and flush port. Turn

the other valve so it is only open to the loop and

flush port (pressure is also applied to the hose

kit in this arrangement).

•

Turn the flush cart pump on and allow the

system to start circulating.

•

With the pump running, turn the return line ball

valve to the off position on the flush cart, “dead

heading” the pump.

•

There should be a maximum of 1” to 2” inches of

drop in the water level in the reservoir. This only

takes about 3-5 seconds.

•

Next, turn the supply line ball valve to the off

position on the flush cart (isolates the flow

center from the flush cart).

•

Now that the system is isolated from the

reservoir the pump can be turned off. Do not

open the main flush cart ball valves yet.

•

Connect the water supply back to the discharge

line hose connection, and open the ball valve.

Turn on the water supply and leave it on for 20

to 30 minutes. This will stretch the pipe properly

to insure that the system will not have a “flat”

loop during cooling operation.

•

Once the loop is pressured (recommended

pressure on initial start up is 50 to 70 psi), turn

the water supply off. Turn off the discharge line

ball valve, and disconnect the water supply.

Maximum pressure should never

exceed 100

psi under any circumstance!

Section 6: Unit Piping Installation

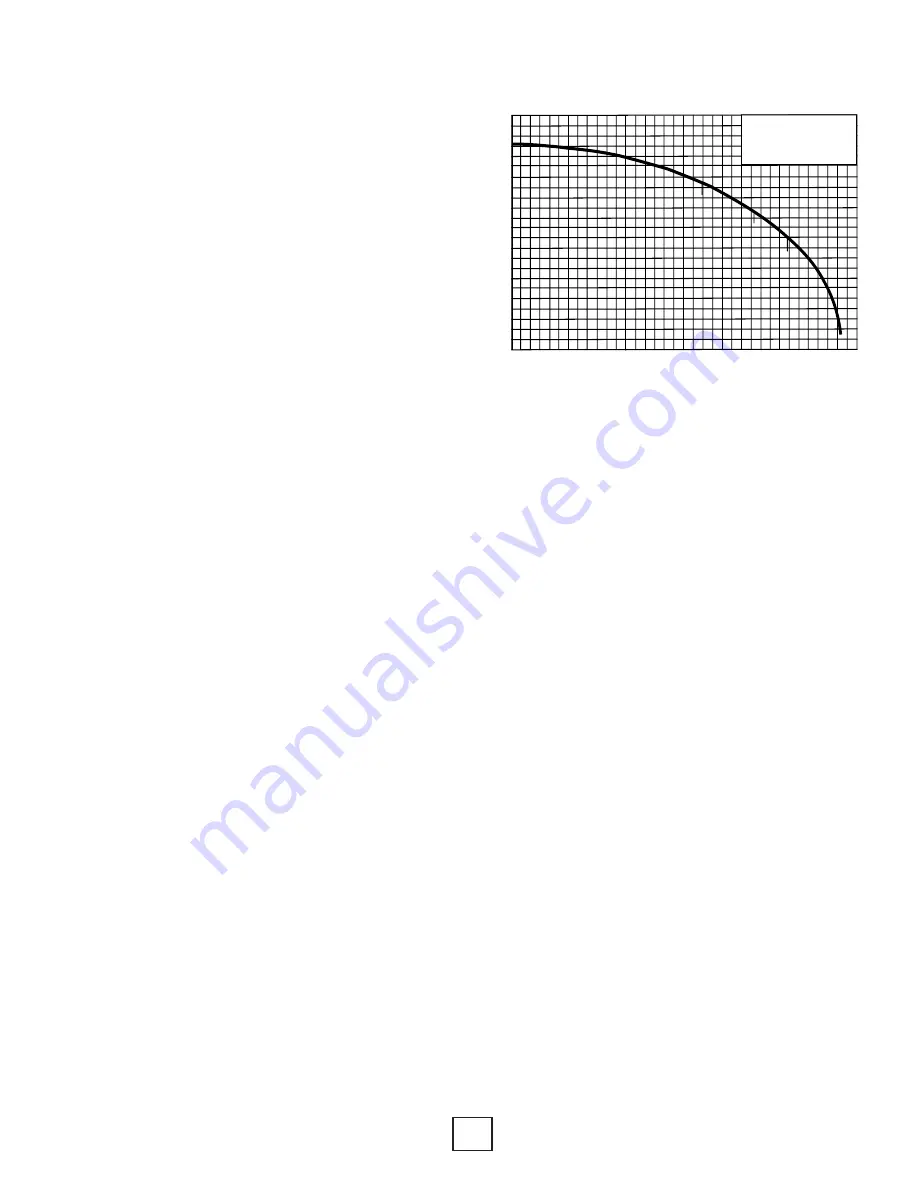

0 10 20 30 40 50 60 70 80 90

CAPACITY - U.S. GPM

120

110

100

90

80

70

60

50

40

30

20

10

Total H

ead in F

eet

SUCTION LIFT

25’

20’

15’

Meyers QP-15

1-1/2 HP Self-Priming

Centrifugal Pump

Figure 19: Flush Cart Pump Curve

•

Turn the 3-way valves on the flow center back

to the normal operation mode, which closes the

flush port connections.

•

Open the ball valves on the flush cart to relieve

pressure on the hoses. Disconnect the hoses

from the flow center.

Note:

Pressurized flow centers and Grundfos UP

series pumps need a minimum of 3psi on the

suction side of the pump to operate. Maximum

operating pressure is 100 psi.

Loop static pressure will fluctuate with the

seasons. Pressures will be higher in the winter

months than during the summer months. In

the cooling mode the heat pump is rejecting

heat, which relaxes the pipe. This fluctuation

is normal and needs to be considered when

charging and pressuring the system initially.

Typical operating pressures of an earth loop are

15 to 50 psi.