omnigrad MTR 44, TR 45

Hauser

5

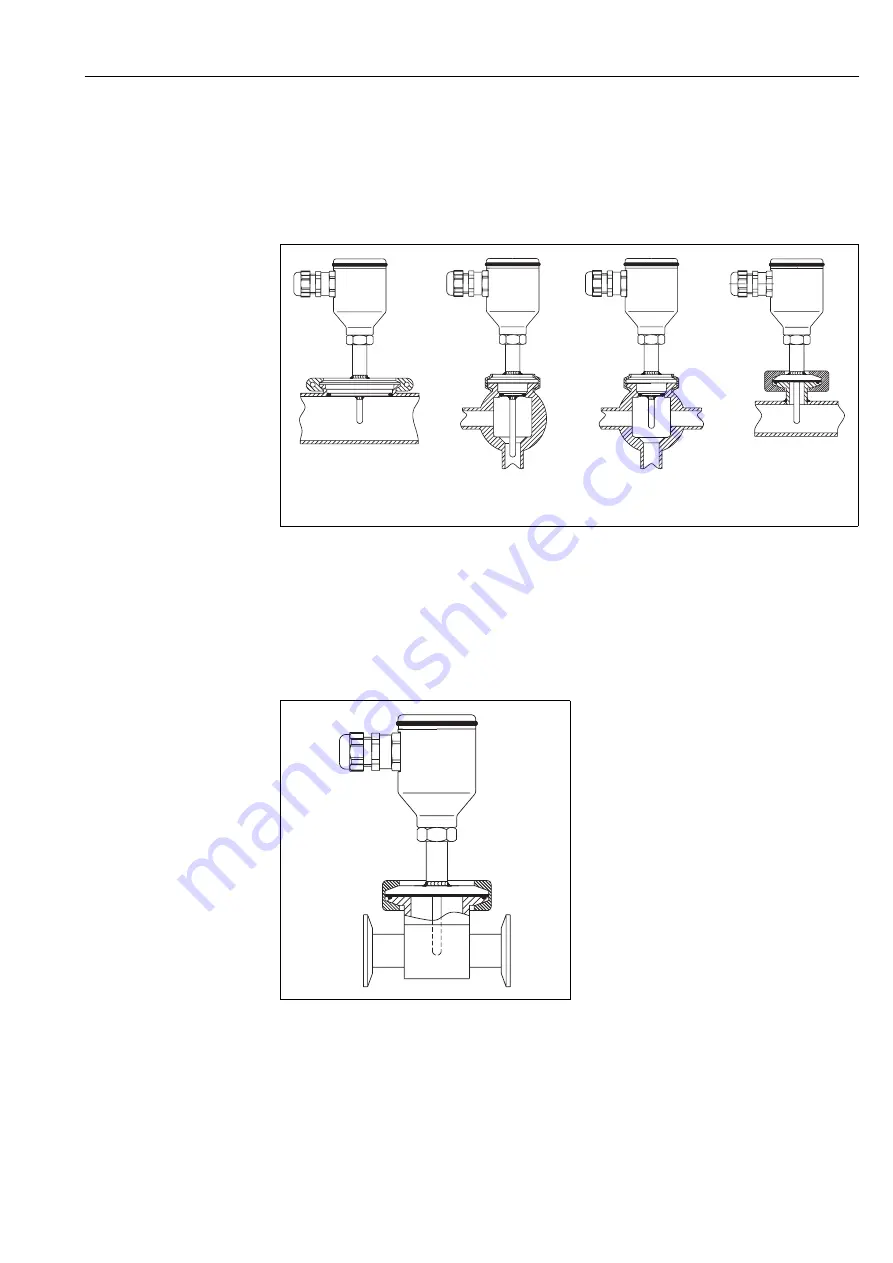

Suitable solutions for the installation of the sensors in small pipes are shown in figure 3.

In hygienic applications, a good, strict, installation rule consists in not to leave any dead spaces along the flow

of the process fluid.

The required flush-mounting can be achieved by the connection Varivent

®

, G1" Liquiphant M type (+ purpose

built adaptor).

The clamp flanges can also partly fulfil this requirement, if the Tri-Clamp

®

components 7IMPS or TL7IWWMS

(Instrument Tees) are used (see the related figure 4).

Fig. 3:

Installation solutions in small pipes

For other connection arrangements, the diagram in figure 2 should be followed [h <= d/2].

For weld-in connections, care should be taken by the user in the execution of the welding on the process side

(suitable weld material, welding radius > 3 mm, absence of pits, folds, crevices, …).

The use of purely threaded, Ingold and metal-to-metal joints is not recommended by some hygienic design

standards (i.e. 3-A

®

Standard 74-02 and Document 8 from EHEDG). This is the reason why E+H Temperature

division doesn't suggest those solutions in "sanitary" applications. Moreover often metal-to-metal couplings can

only be used effectively once.

Regarding corrosion, the basic material of the wetted

parts (SS 316L/1.4435) is capable to tolerate com-

mon corrosive media up to high temperatures.

When disassembling the sensors, new gaskets equiv-

alent to the originals and specific torques must be

employed for the re-assembling procedure. This will

ensure the stated IP (Ingress Protection) grade of the

enclosures.

To avoid problems due to condensation when the

ambient has a high humidity rate and the process is at

a low temperature, a plastic housing (i.e. model

TA20B) can be an effective choice.

Fig. 4:

Installation with the Tri-Clamp

®

component 7IMPS

Varivent D=50 mm

for pipes DN25

Varivent D=31 mm

for pipes DN10/15

Microclamp

or miniclamp